Formula of kerb, production device of kerb and assembly line production method

A production line and production device technology, applied in the direction of chemical instruments and methods, supply devices, unloading devices, etc., can solve the problems of high efficiency, short cycle, low porosity, consistent color difference, smooth finish, high smoothness, consistency Good, smooth and delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

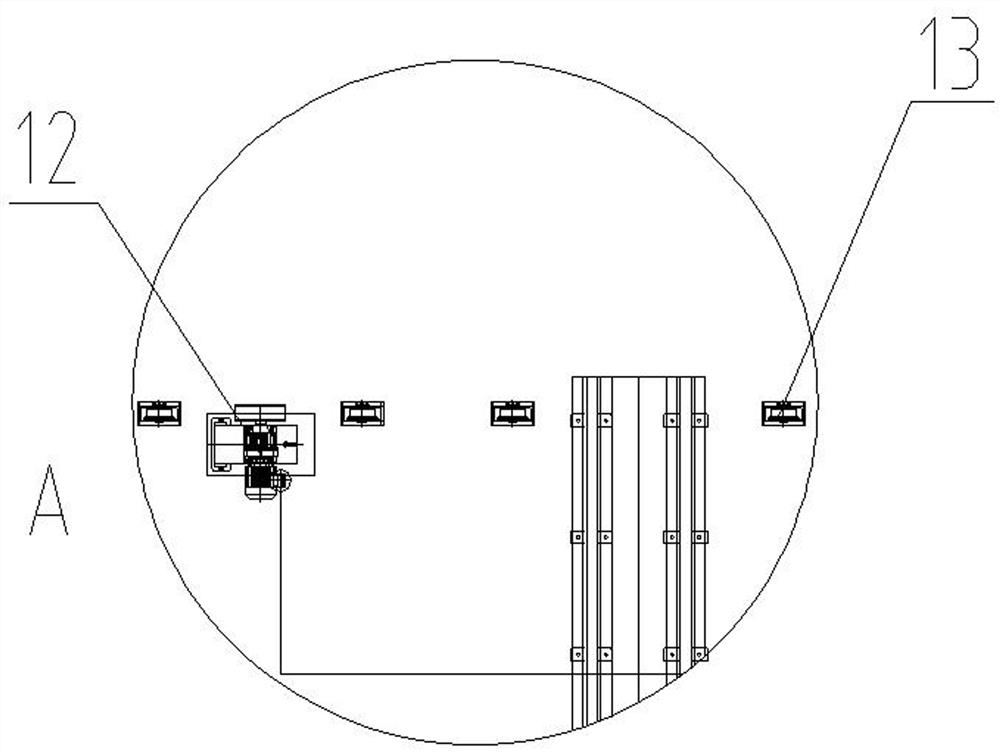

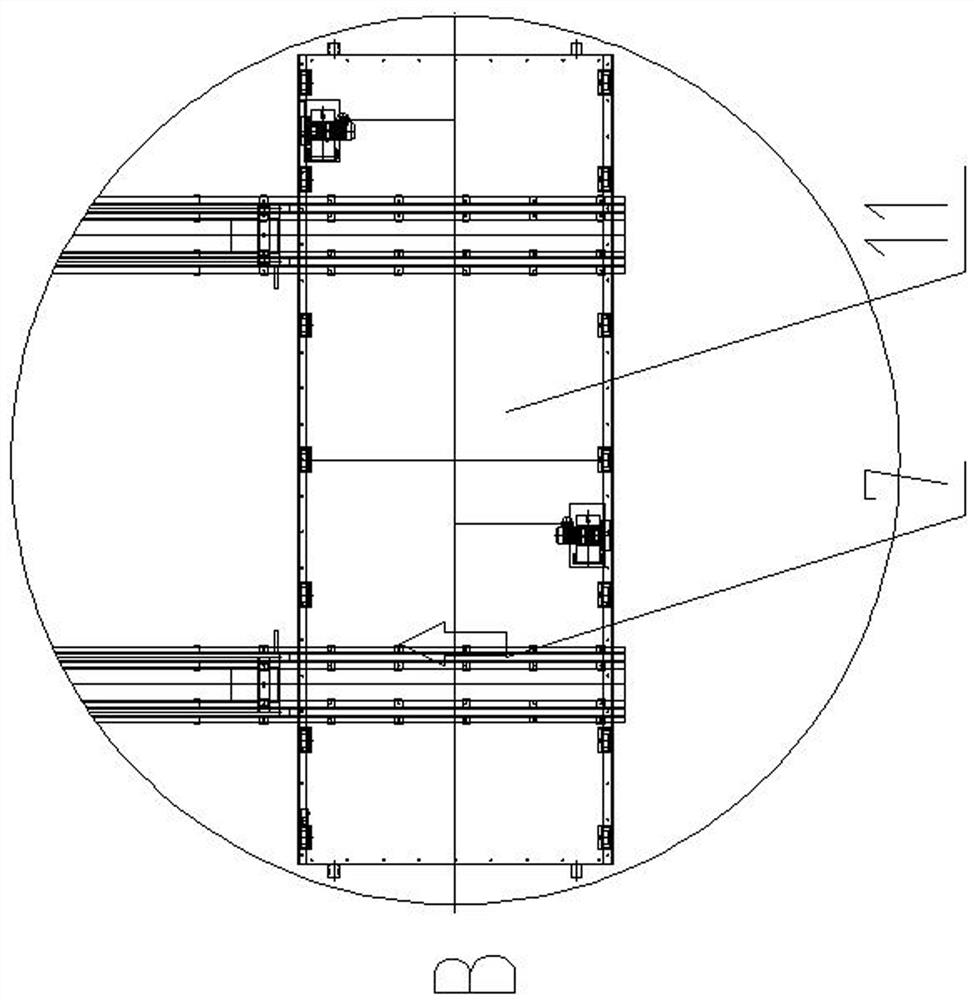

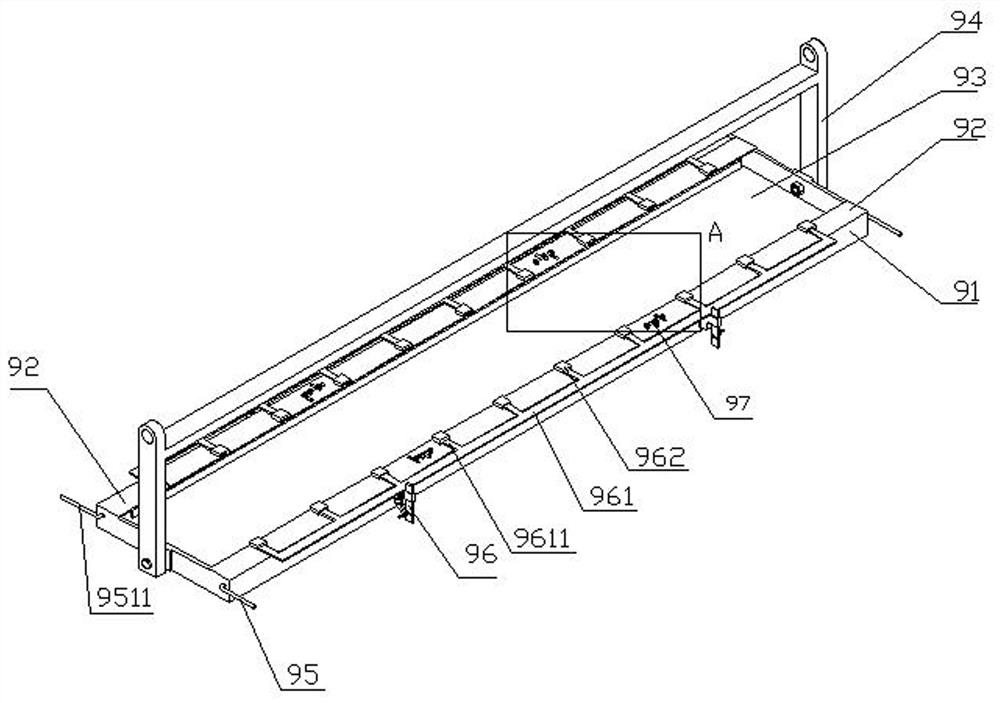

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

[0046] The formula of a kind of road curb of the present invention comprises cementitious material, admixture, fine aggregate, coarse aggregate, water, and the weight sum of above-mentioned material cementitious material, admixture, fine aggregate, coarse aggregate and water is 100%. , the ratio of each material is as follows: cementitious material 16-22% by mass, admixture 0.32-0.66% by mass, fine aggregate 30-35% by mass, and coarse aggregate 40-45% by mass , water accounts for 6.5-7.5% by mass; the admixture in this embodiment is an aliphatic water reducer; the cementitious material includes cement, fly ash and mineral powder, wherein the model of the mineral powder is mineral powder S95; fine aggregate The quality of the aggregate includes sand, and the coarse aggregate includes stones. In this embodiment, the curbstones include standing stones and flat stones. 1m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com