Fully-automatic kraft paper packing machine

A kraft paper, fully automatic technology, applied in packaging, transportation packaging, wrapping objects, etc., can solve the problems of slow packaging speed and high cost, and achieve the effect of convenient folding and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

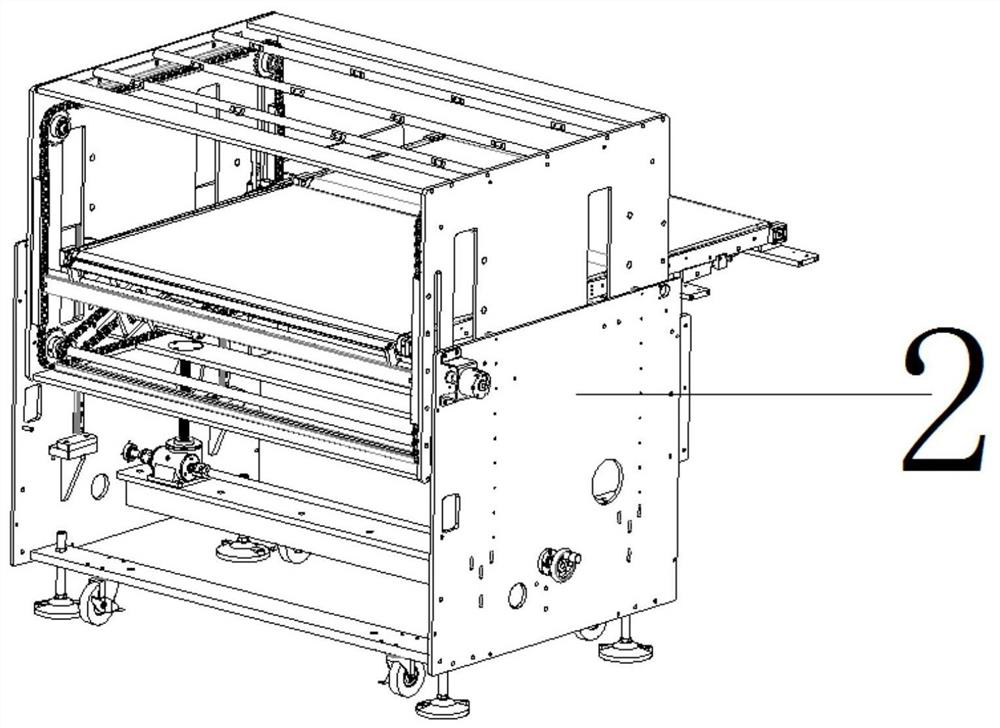

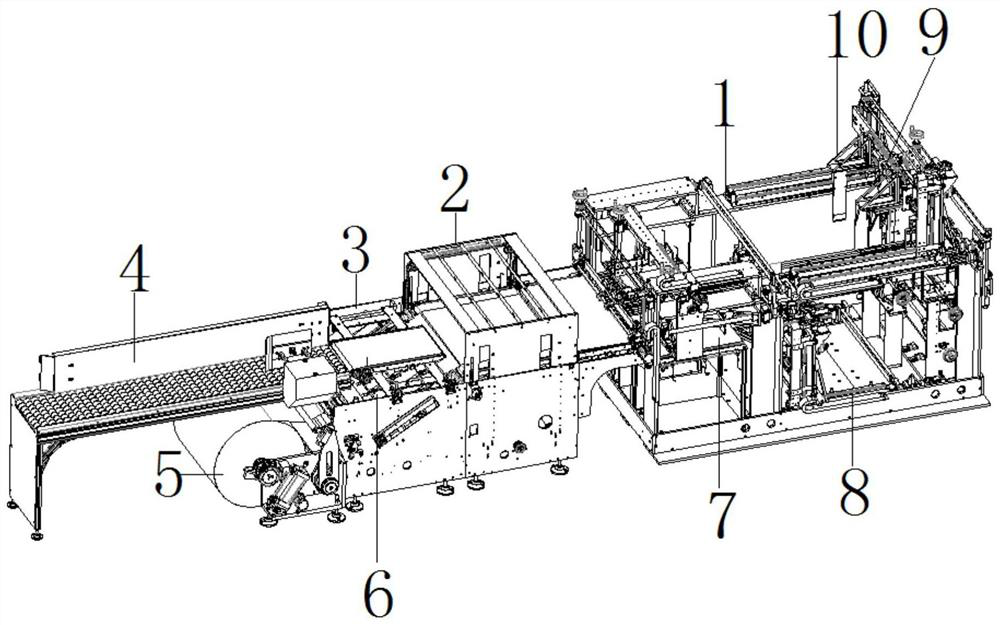

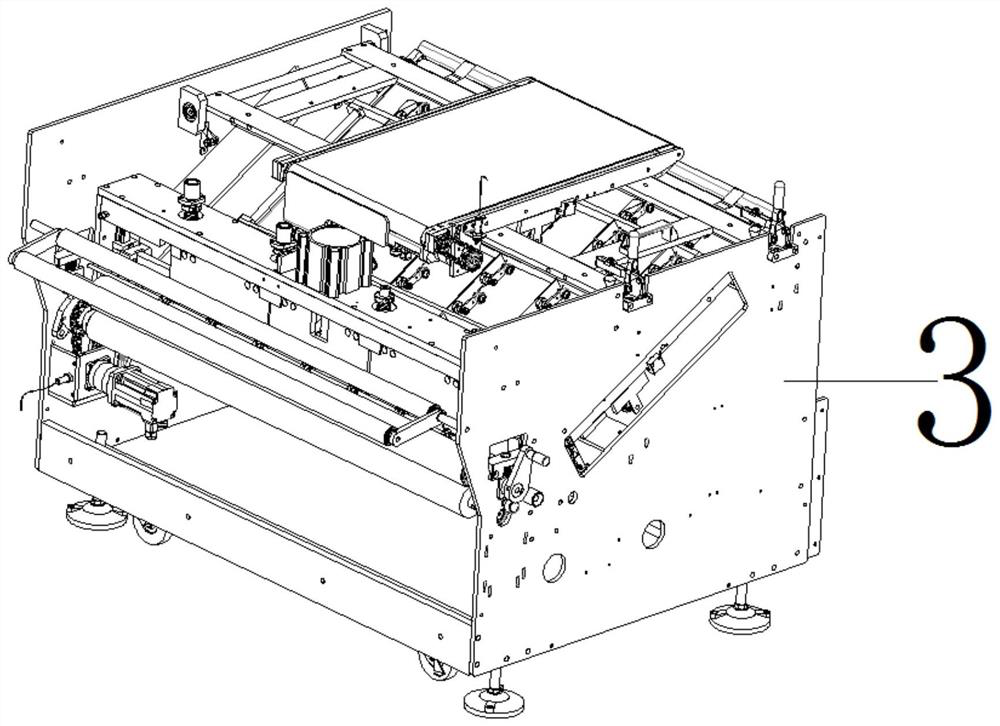

[0029] see figure 1 , 2 , 3, 4, 9, a fully automatic kraft paper automatic packing machine, including the folding module assembly 1 and the main conveyor belt, the folding module assembly 1 is connected to the left side of the coating module 2, and the coating module 2 is composed of the main conveyor belt and the driving lever Composition, the lever is fixed by a 180-degree rotatable structure, the left side of the coating module 2 is connected with a cutting and conveying module 3, the cutting and conveying module 3 is composed of a blade and a cylinder 12, and the front and rear ends of the blade are connected to the cylinder 12 through screws , the left side of the cutting and conveying module 3 is connected with the material buffer drum line module 4, and the roll paper feeding module 5 is arranged under the material buffer drum line module 4, and the roll paper feeding module 5 is composed of a feeding device 11, a motor 13 and a cylinder 12 , the front and rear ends of...

Embodiment 2

[0032] see figure 1 , 5 , 6, 7, 8, a fully automatic kraft paper automatic packing machine, including the folding module assembly 1, the folding module assembly 1 includes the first folding XY module 7, the second folding XYZ module 8, the first folding Three XYZ modules 10 and adhesive cloth modules 9, the first hemming XY module 7 is fixed on the left side of the second hemming XYZ module 8, the second hemming XYZ module 8 is fixed on the third XYZ At the bottom of the module 10, the third XYZ module 10 is connected with the adhesive tape module, and the first folding XY module 7 includes an X axis and a Y axis, and the X axis and the Y axis are fixed with baffles by screws, and the X axis and The Y-axis is driven by the motor 13 to move the threaded shaft. The second folding XYZ module 8 is composed of the X-axis, Y-axis and Z-axis. The X-axis, Y-axis and Z-axis are all fixed with baffles by screws. , Y-axis and Z-axis are all driven by the motor 13 to move the threaded s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com