Production method of low polycyclic aromatic hydrocarbon capsanthin

A production method and a technology for polycyclic aromatic hydrocarbons, which are applied in the field of food additive refining, can solve the problems that the yield of capsicum red cannot be guaranteed, cannot be satisfied, and the industrialization development of capsicum red is affected, and the industrial production is convenient, the operation is simple, and the process is simplified. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

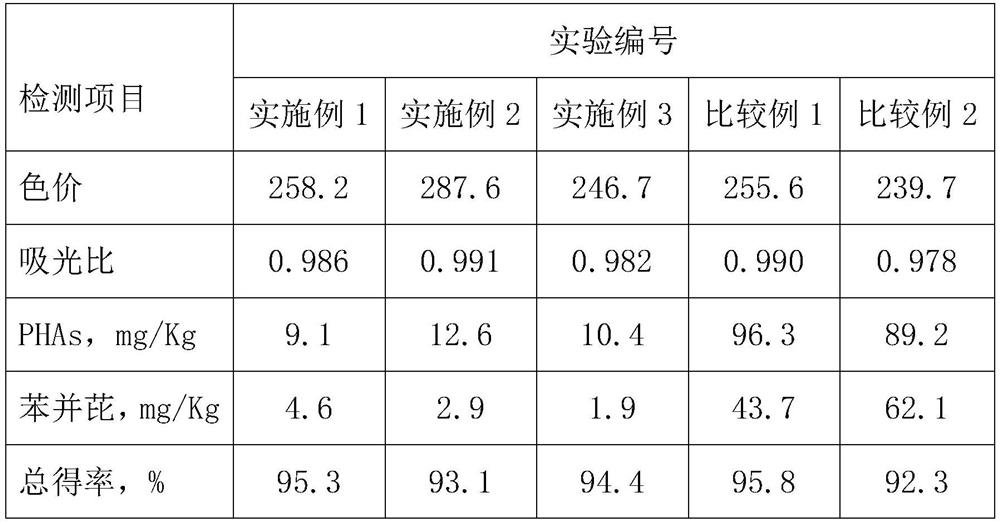

Examples

Embodiment 1

[0023] a) Dry the mature peppers at 30°C, crush them, and granulate them to obtain pepper granules. Take 3000Kg of pepper granules (with a color value of 16.6) and use a flat-rotating continuous extractor to extract the vegetable oil as an extraction solvent. solvent, the spraying temperature is 45°C, the spraying volume is 1000L / h, and the pigment leachate is obtained by extraction. Mix the pigment leachate with 70% ethanol in a liquid-liquid extractor at 45°C and 200r / min to remove the spicy substance, and the flow rate of the pigment leachate is 1m 3 / h, 70% ethanol flow rate is 2m 3 / h, to obtain the off-pepper pigment extract.

[0024] b) The despiced pigment leachate is subjected to chromatographic column adsorption with 100 mesh activated carbon and 100 mesh diatomaceous earth mixed in 5:1 as filler at a flow rate of 1Bv / h, and the amount of chromatographic column filler is 30kg, collected The lower port effluent is obtained to remove the capsanthin solution of polycy...

Embodiment 2

[0027] a) Dry the mature peppers at 30°C, crush them, and granulate them to obtain pepper granules. Take 3000Kg of pepper granules (with a color value of 17.6), use a flat-rotating continuous extractor, and use vegetable oil as an extraction solvent. solvent, the spraying temperature is 45°C, the spraying volume is 1000L / h, and the pigment leachate is obtained by extraction. Mix the pigment leachate and 70% ethanol in a liquid-liquid extractor at 45°C and 200r / min to remove the spicy substance, the flow rate of the pigment leachate is 1m3 / h, and the flow rate of the 70% ethanol is 2m3 / h to obtain Despiced pigment extract.

[0028] b) The depigmented pigment leachate is mixed with 100 mesh activated carbon, activated clay and diatomaceous earth at a flow rate of 1.5Bv / h in a 4:1:1 ratio for chromatography column adsorption as filler, the amount of chromatography column filler 50kg, collect the lower port effluent to obtain the capsanthin solution for removing polycyclic aromat...

Embodiment 3

[0031] a) Dry the mature peppers at 30°C, crush and granulate to obtain pepper granules, take 3000Kg of pepper granules (color value is 16.9), use a flat-rotating continuous extractor, and use vegetable oil extraction solvent as extraction solvent, the spraying temperature is 45°C, the spraying volume is 1000L / h, and the pigment leachate is obtained by extraction. Mix the pigment leachate with 70% ethanol in a liquid-liquid extractor at 45°C and 200r / min to remove the spicy substance. The flow rate of the pigment leachate is 1m3 / h, and the flow rate of the 70% ethanol is 2m 3 / h, to obtain the off-pepper pigment extract.

[0032] b) The depigmented pigment leachate is subjected to chromatographic column adsorption mixed with 200 mesh activated carbon and 80 mesh activated clay at a rate of 1.2Bv / h in a ratio of 7:1 as filler, and the amount of chromatographic column filler is 70kg. The lower port effluent is obtained to remove the capsanthin solution of polycyclic aromatic hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com