Catalyst for synthesizing N, N-diethyl propargylamine and preparation method thereof

A technology of diethylpropargylamine and catalyst is applied in the field of catalyst for synthesizing N,N-diethylpropargylamine and its preparation field, and can solve the problem of reducing the yield and purity of N,N-diethylpropargylamine , The copper salt catalyst is not easy to recover, the catalyst is rapidly deactivated, etc., to reduce the probability of side reactions, shorten the reaction time, and improve the selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

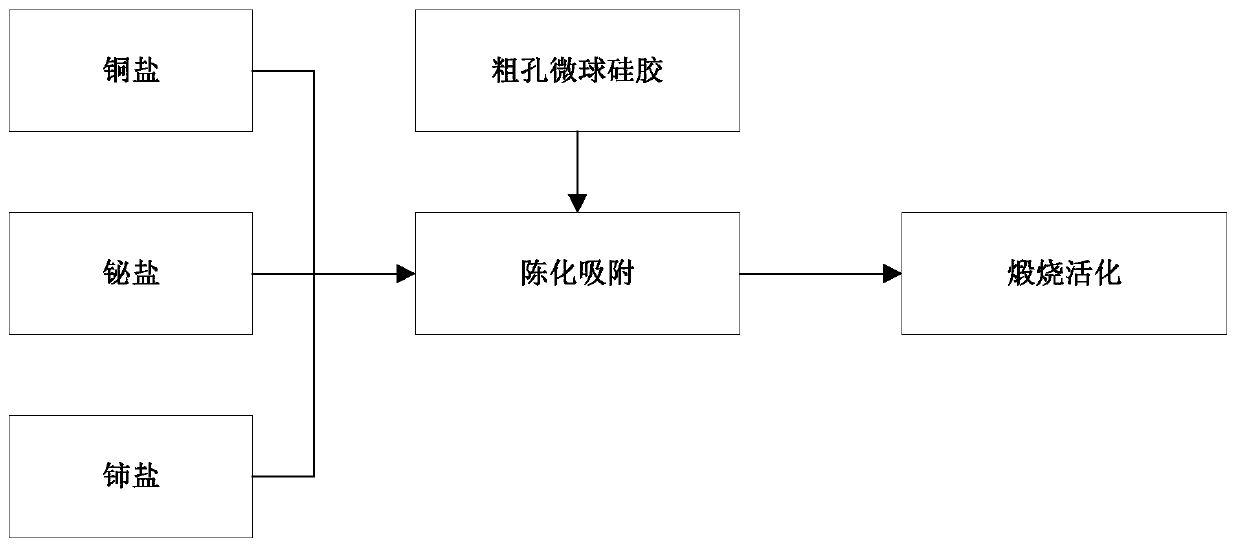

[0017] The present invention also provides a method for preparing a catalyst for synthesizing N,N-diethylpropynylamine, comprising the following steps: after dissolving the mixture of copper salt, bismuth salt and cerium salt, a metal salt solution is obtained, and the The coarse-porous microsphere silica gel after calcining and expanding the pores is aged and adsorbed in the metal salt solution, and then calcined and activated to obtain the finished product.

[0018] As a preferred embodiment of the present invention, the mass of the coarse-porous microsphere silica gel is 1 to 8 times the mass of the mixture of copper salt, bismuth salt and cerium salt; the metal salt solution uses deionized water as a solvent, and the deionized The quality of water is 5 to 20 times that of the mixture of copper salt, bismuth salt and cerium salt; by optimizing the amount of coarse-pore microsphere silica gel and metal salt solution, the catalytic efficiency of the catalyst can be improved an...

Embodiment 1

[0024] Example 1 of the present invention provides a catalyst for synthesizing N,N-diethylpropynylamine, in which the molar ratio of copper salt, bismuth salt and cerium salt is 1:0.0253:0.0324.

[0025] The catalyst is prepared as follows:

[0026] (1) Add 250g of deionized water to a 500ml single-necked flask, add 20g of copper sulfate, 1g of bismuth chloride and 1g of cerium chloride to the single-necked flask in turn under stirring at room temperature, then raise the temperature to 60°C, heat and dissolve for 2 to 4 hours, to obtain a metal salt solution;

[0027] (2) After calcining 100 g of coarse-pore microsphere silica gel in a muffle furnace at 400 ° C for 4 hours, cool to room temperature, then add the calcined and expanded coarse-pore microsphere silica gel into the well-insulated metal salt solution, and age chemical adsorption for 30h;

[0028] (3) Dry the coarse-porous microsphere silica gel aged in step (2) to remove water, and then calcinate and activate it i...

Embodiment 2

[0031] Example 2 of the present invention provides a catalyst for synthesizing N,N-diethylpropynylamine, in which the molar ratio of copper salt, bismuth salt and cerium salt is 1:0.0223:0.0206.

[0032] The catalyst is prepared as follows:

[0033] (1) Add 300 g of deionized water to a 500 ml single-necked flask, add 30 g of copper chloride, 2 g of bismuth nitrate and 2 g of cerium nitrate to the single-necked flask successively under stirring at room temperature, then raise the temperature to 60° C., heat and dissolve for 2 to 4 hours, and obtain Metal salt solution;

[0034] (2) After calcination of 120 g of coarse-pore microsphere silica gel in a muffle furnace at 400 ° C for 6 hours, cool to room temperature, then add the calcined and expanded coarse-pore microsphere silica gel into the well-insulated metal salt solution, and age chemical adsorption for 24h;

[0035] (3) Dry the coarse-porous microsphere silica gel aged in step (2) to remove water, and then calcinate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com