Construction method of mixed plastic runway

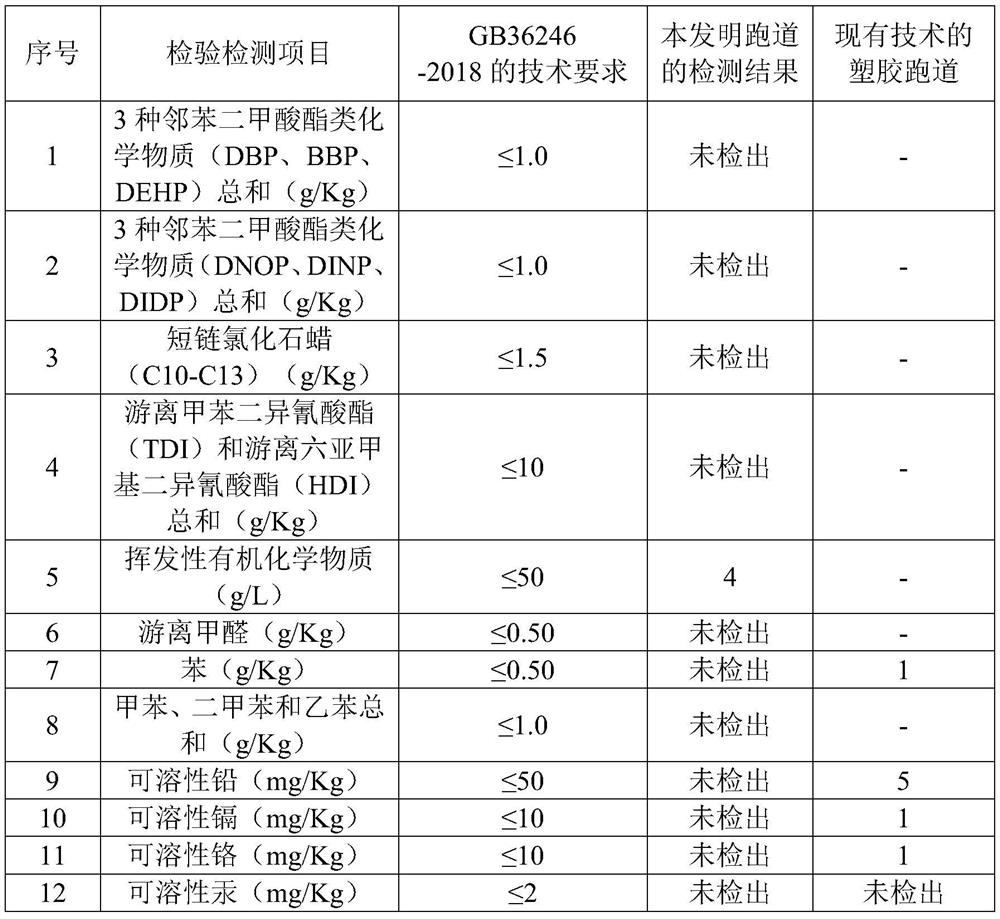

A construction method and technology of plastic runway, applied in the direction of roads, roads, road repair, etc., can solve the problems of complex process, high content of harmful chemical substances, many laying processes, etc., and achieve long service life, less chemical toxic substances, and reduce repairs. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A construction method for a hybrid plastic runway, comprising the following steps:

[0031] (1) Preparatory work before construction:

[0032] (1) cleaning site

[0033] Clean up the excess dirt on the site and the powder left over from grinding and other impurities that affect the construction of the plastic runway, sprinkle water on the ground, check and mark the waterlogged parts with chalk.

[0034] (2) Determination of ground moisture

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com