Multi-layer composite sound-absorbing plate beneficial to air transmission and sound insulation

A multi-layer composite and sound-absorbing panel technology, which is applied in the field of noise reduction, can solve the problems of sound-absorbing panels such as weakened air permeability, narrow tuning frequency, and large floor space, so as to reduce floor space, improve acoustic radiation impedance, and improve The effect of the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

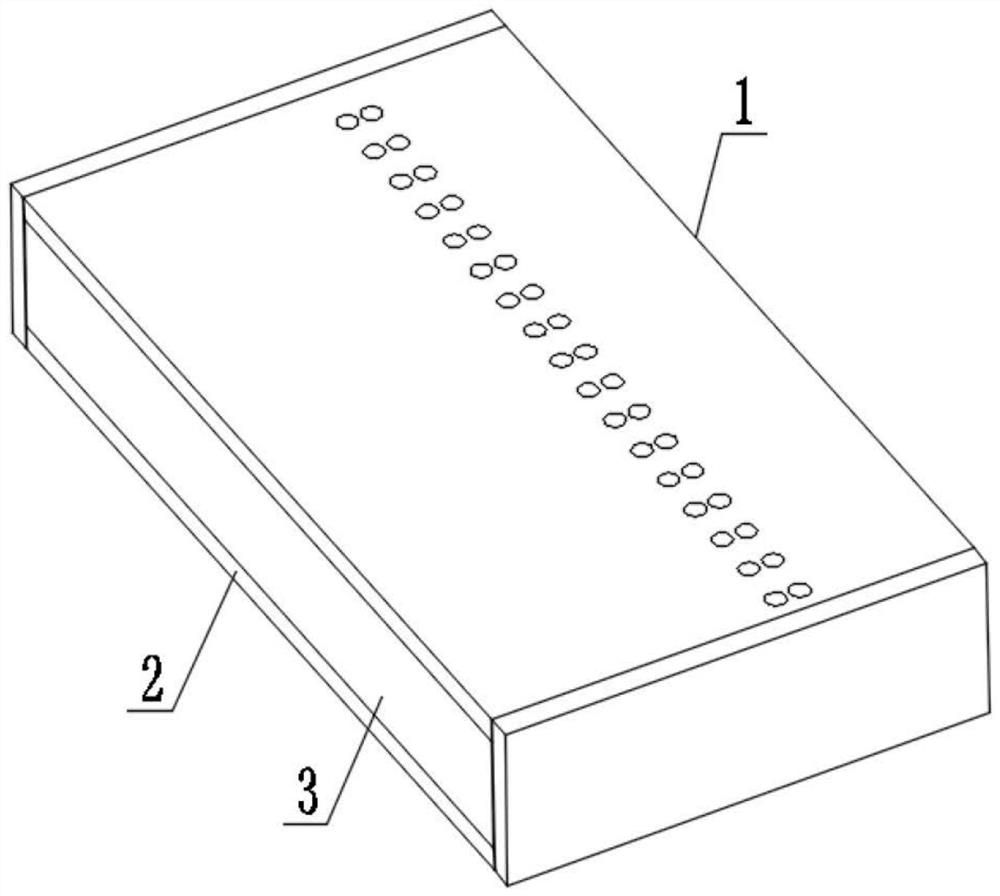

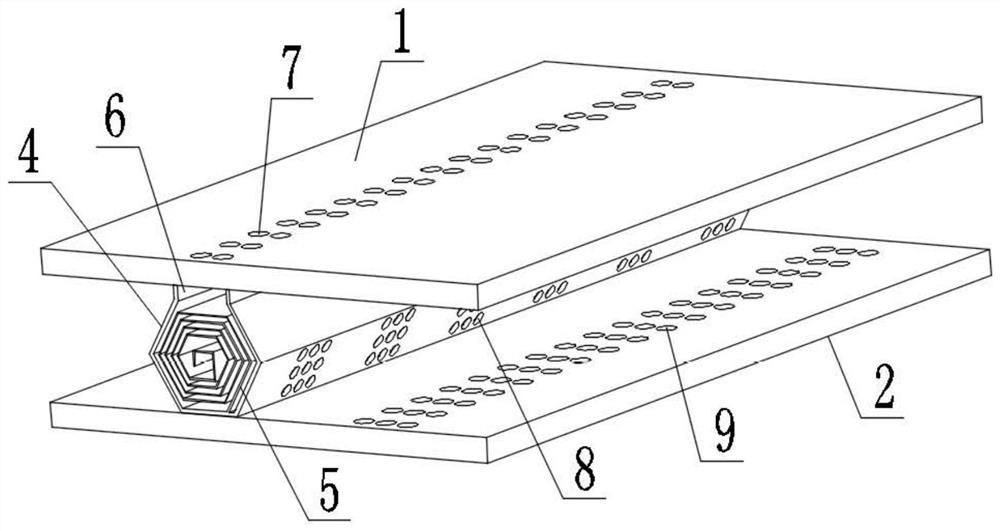

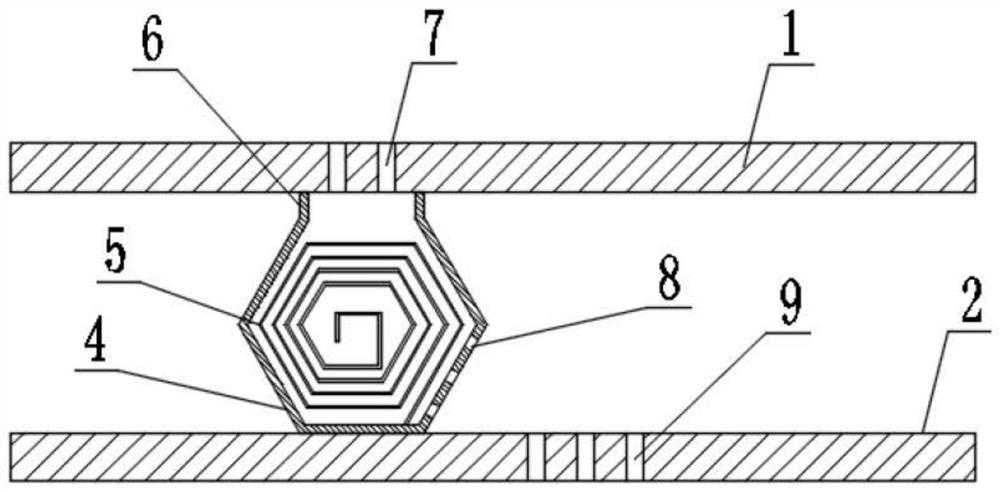

[0021] Such as figure 1 and figure 2 As shown, a multi-layer composite sound-absorbing panel that is conducive to air permeability and sound insulation includes a sound-absorbing panel with an open structure, and the sound-absorbing panel includes an upper top board 1 and a lower bottom board 2, and the A side plate 3 with closed side ends; a cylinder 4 with the same length as the sound-absorbing panel is arranged between the upper top plate 1 and the lower bottom plate 2, the bottom of the cylinder 4 is fixed to the lower bottom plate 2, and the top of the cylinder 4 is open and set There is a sound guide channel 6 fixed to the upper roof 1, and a spiral plate 5 having the same cross-sectional shape as the cylinder 4 is arranged inside the cylinder 4, and the starting end of the spiral plate 5 is located at the bottom and fixed to the bottom of the cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap