A high-efficiency engine oil filter that avoids clogging

A technology for avoiding blockage and oil filtration, applied in the field of oil filtration, can solve problems such as affecting normal use, difficult to remove filter residues, and small filtration area, and achieve the effect of preventing oil leakage, improving life, and enhancing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

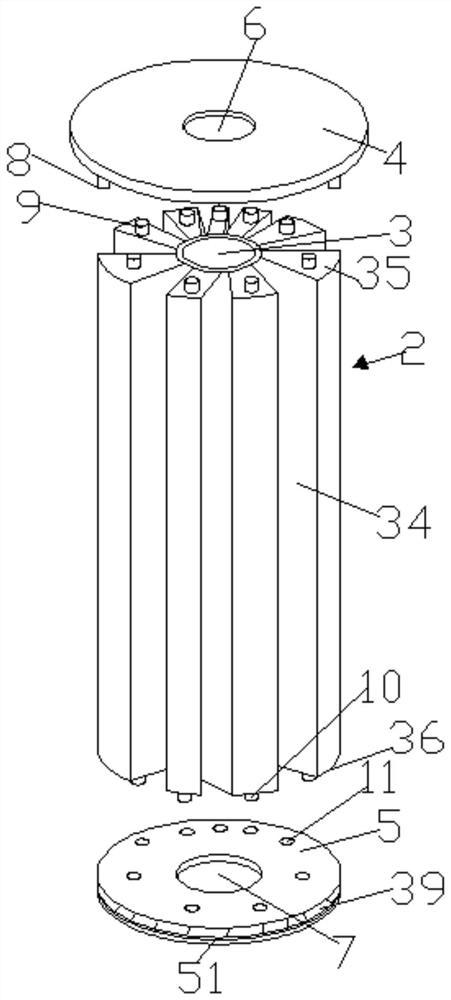

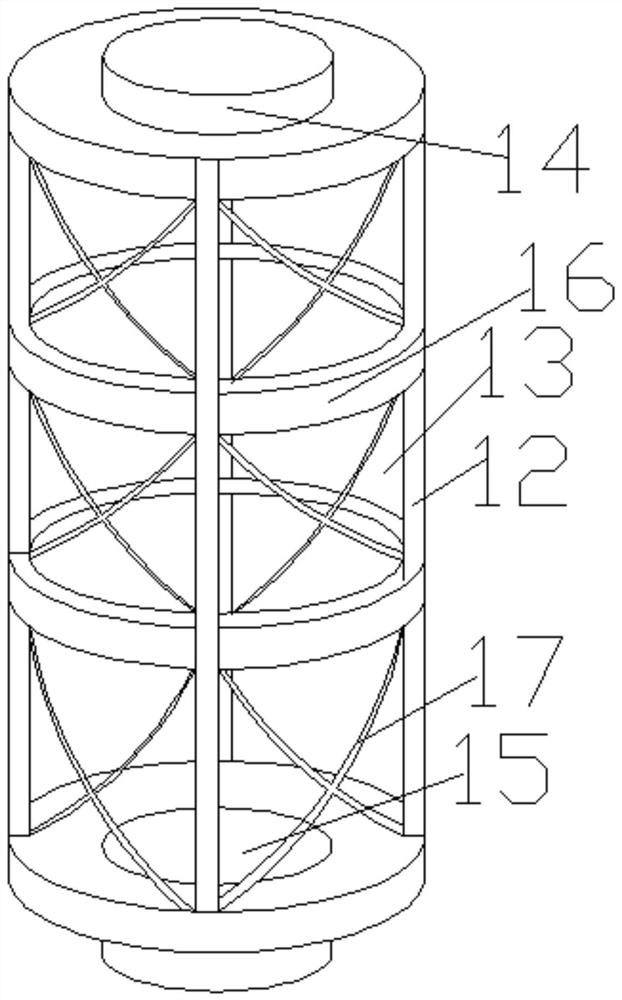

Embodiment 1

[0032]SeeFigure 1-7In accordance with an embodiment of the present invention, an air filter 2 is avoided, including housing 1 and filter 2, and the cartridge 2 is opened, and the filter 2 is connected to the top cover 4, The filter cartridge 2 is attached to the lower end cap 5, and the upper end cover 4 is opened, and the first through hole 6 that matches the oil flow chamber 3 is opened, and the lower end cover 5 is opened on the oil flow cavity. 3 Matching the second through hole 7, the lower end cap 5, the upper end cover 4 and the filter cartridge 2 secure a plurality of positioning blocks 8 at the bottom side of the upper end cap 4, the upper end cap 4 The filter cartridge 2 is located between several positioning blocks 8, and the filter cartridge 2 is connected to the positioning block 8, and a plurality of first circular blocks 9 are uniformly fixed at the top end of the filter 2, the filter cartridge. 2 The bottom end is uniformly fixed, and several second circular blocks 1...

Embodiment 2

[0034]Seefigure 1 For the oil flow chamber 3, the oil flow chamber 3 extends in the center axial direction of the filter 2, and the oil flow chamber 3 penetrates both ends of the filter 2.

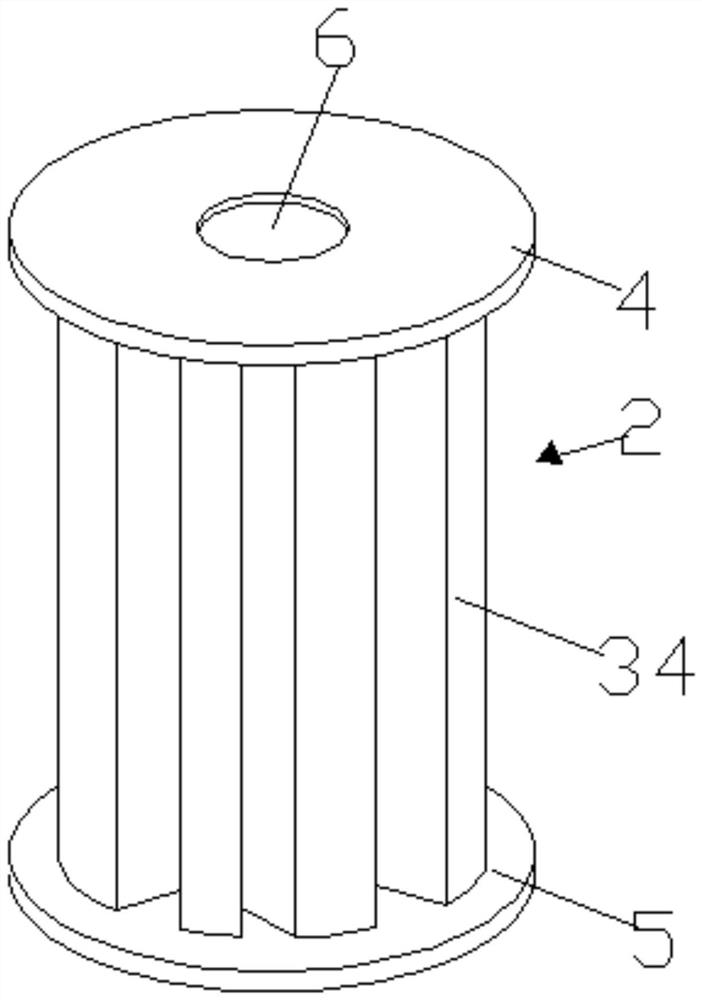

Embodiment 3

[0036]Seefigure 1 For the filter cartridge 2, the filter cartridge 2 is wound by a wavy filter paper, and the filter cartridge 2 has a plurality of filter paper folded 34, which is radially arranged by a central axis, which is folded. The upper fold 35 of 34 is connected to the upper end cover 4, and the lower fold 36 of the filter paper fold 34 is connected to the top end cap 5, and the lower end cover 5 is equal to the filter 2. The diameter, the upper end cover 4 diameter is larger than the diameter of the filter 2, and several first circular blocks 9, several second circular blocks 10, and the filter 2 material are all consistent and integrated. Several first circular blocks 9 are disposed on the corresponding upper fold 35, and several second circular blocks 10 are disposed on the corresponding lower fold 36.

[0037]Through the above-described above scheme of the present invention, it is advantageous effect: the area where the contact is increased, and the stability of the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com