Bolt and self-locking nut assembly

A self-locking nut and bolt technology, used in nuts, bolts, threaded fasteners, etc., can solve problems such as short service life, difficult disassembly, and reduced connection strength, and achieve improved corrosion resistance, good corrosion resistance, and use. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

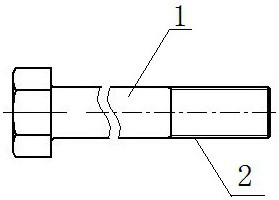

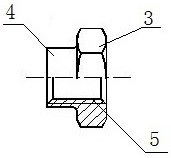

[0023] The bolt and self-locking nut assembly of the present invention, such as Figure 1 to Figure 2 As shown, it includes a bolt 1 and a self-locking nut 3, the bolt 1 is provided with an external thread 2, and the self-locking nut is provided with an internal thread 5, so that the bolt 1 and the self-locking nut 3 can be screwed together. The opening of one end of the self-locking nut 3 along the axial direction is also provided with a closing structure 4. The closing structure 4 is a quadrilateral when viewed from the side, so that the bolt 1 and the self-locking nut 3 are screwed to a certain degree. Structure 4 The mutual extrusion and friction between the inner thread and the outer thread 2 of the bolt prevent the bolt 1 and the self-locking nut 3 from loosening, thereby achieving the self-locking effect. In other embodiments, the closing structure may be other structures, such as other non-circular structures such as an ellipse viewed from a side view.

[0024] In ord...

specific Embodiment 2

[0046] The difference from Example 1 is that the electroplated anti-corrosion layer is an electroplated zinc-nickel alloy layer, and the electroplated zinc-nickel alloy layer has better corrosion resistance, and is suitable for harsh industrial environments and severe marine environments.

specific Embodiment 3

[0048] The difference from Example 1 is that the lubricating layer includes a graphite layer and a cetyl alcohol layer, and the graphite layer also has a certain lubricating effect and has better chemical stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com