Flat wire stator assembly and driving motor

A flat wire stator and wire stator technology are applied in the field of flat wire stator components and drive motors, which can solve the problems of increased additional copper loss, large asymmetry, and high material cost, and achieve reduced additional copper loss and small asymmetry. , optimize the effect of the connection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

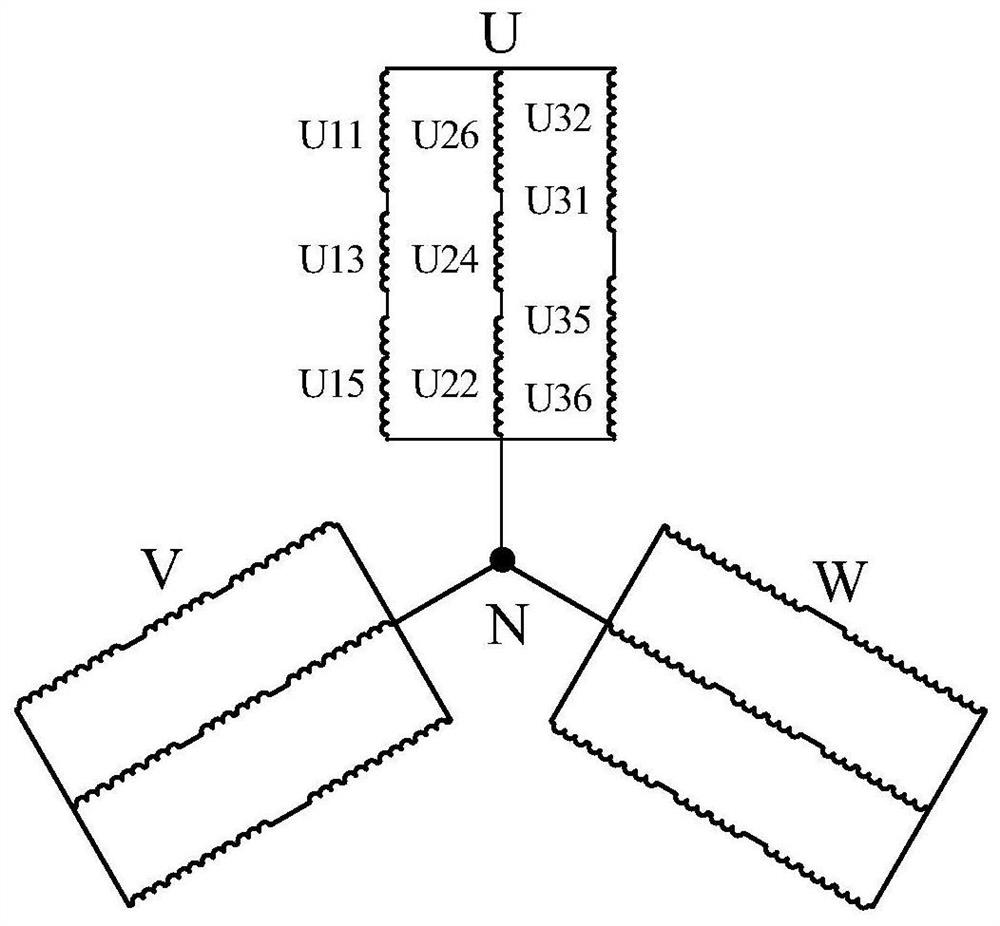

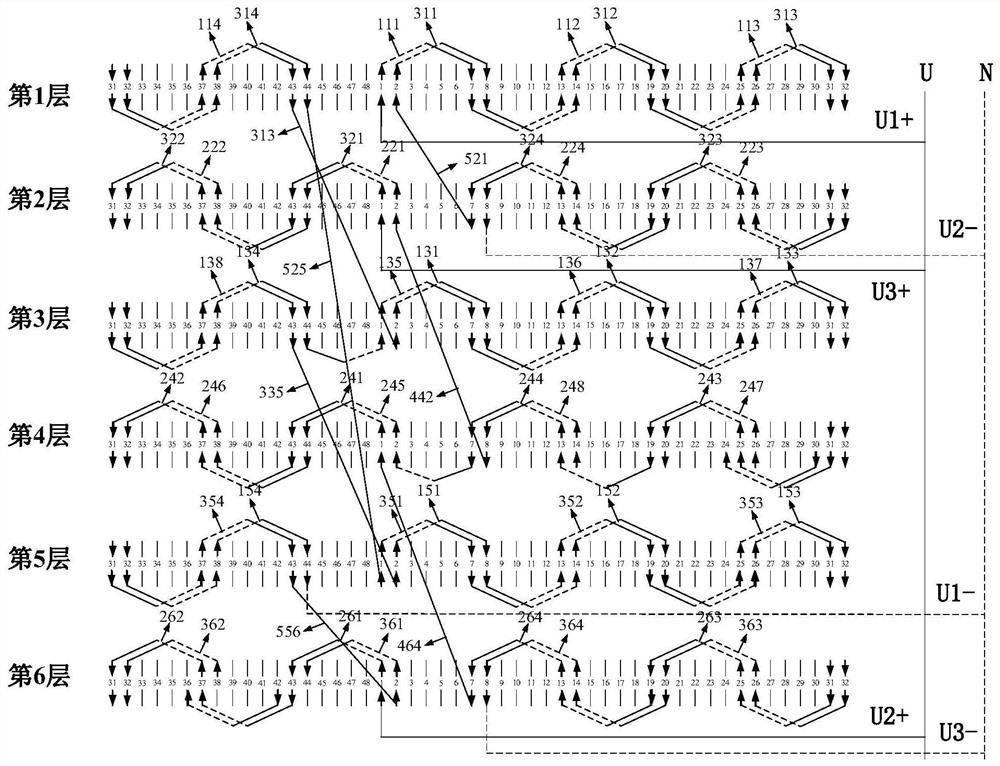

[0056] The three sub-windings of each phase of the stator winding include the first sub-winding, the second sub-winding and the third sub-winding, and the three-phase stator winding is wound in the following way:

[0057] The first sub-winding of the stator winding of each phase includes 3n / 8 coils distributed in the first layer L1 and the second layer L2 of the stator slot 7, and 3n / 8 coils distributed in the third layer L3 and the fourth layer L4 of the stator slot 7. n / 4 coils, and 3n / 8 coils distributed in the fifth layer L5 and the sixth layer L6 of the stator slot 7 .

[0058] The second sub-winding of the stator winding of each phase includes 3n / 8 coils distributed in the first layer L1 and the second layer L2 of the stator slot 7, and 3n / 8 coils distributed in the third layer L3 and the fourth layer L4 of the stator slot 7. n / 4 coils, and 3n / 8 coils distributed in the fifth layer L5 and the sixth layer L6 of the stator slot 7 .

[0059] The third sub-winding of the st...

Embodiment 2

[0061] The three sub-windings of each phase of the stator winding include the first sub-winding, the second sub-winding and the third sub-winding, and the three-phase stator winding is wound in the following way:

[0062] The first sub-winding of the stator winding of each phase includes n / 4 coils distributed in the first layer L1 and the second layer L2 of the stator slot 7, and n / 4 coils distributed in the third layer L3 and the fourth layer L4 of the stator slot 7. 3n / 8 coils, and 3n / 8 coils distributed in the fifth layer L5 and the sixth layer L6 of the stator slot 7 .

[0063] The second sub-winding of the stator winding of each phase includes 3n / 8 coils distributed in the first layer L1 and the second layer L2 of the stator slot 7, and 3n / 8 coils distributed in the third layer L3 and the fourth layer L4 of the stator slot 7. 3n / 8 coils, and n / 4 coils distributed in the fifth layer L5 and the sixth layer L6 of the stator slot 7 .

[0064] The third sub-winding of the sta...

Embodiment 3

[0066] The three sub-windings of each phase of the stator winding include the first sub-winding, the second sub-winding and the third sub-winding, and the three-phase stator winding is wound in the following way:

[0067] The first sub-winding of the stator winding of each phase includes 3n / 8 coils distributed in the first layer L1 and the second layer L2 of the stator slot 7, and 3n / 8 coils distributed in the third layer L3 and the fourth layer L4 of the stator slot 7. 3n / 8 coils, and n / 4 coils distributed in the fifth layer L5 and the sixth layer L6 of the stator slot 7 .

[0068] The second sub-winding of the stator winding of each phase includes 3n / 8 coils distributed in the first layer L1 and the second layer L2 of the stator slot 7, and 3n / 8 coils distributed in the third layer L3 and the fourth layer L4 of the stator slot 7. 3n / 8 coils, and n / 4 coils distributed in the fifth layer L5 and the sixth layer L6 of the stator slot 7 .

[0069] The third sub-winding of the st...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap