Double-station automatic line drawing machine for shoe materials

An automatic line drawing, double-station technology, applied in the direction of shoe-making machinery, footwear, clothing, etc., can solve the problems of increased labor cost, high labor intensity, and difficult operation, saving computing time and improving processing efficiency. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

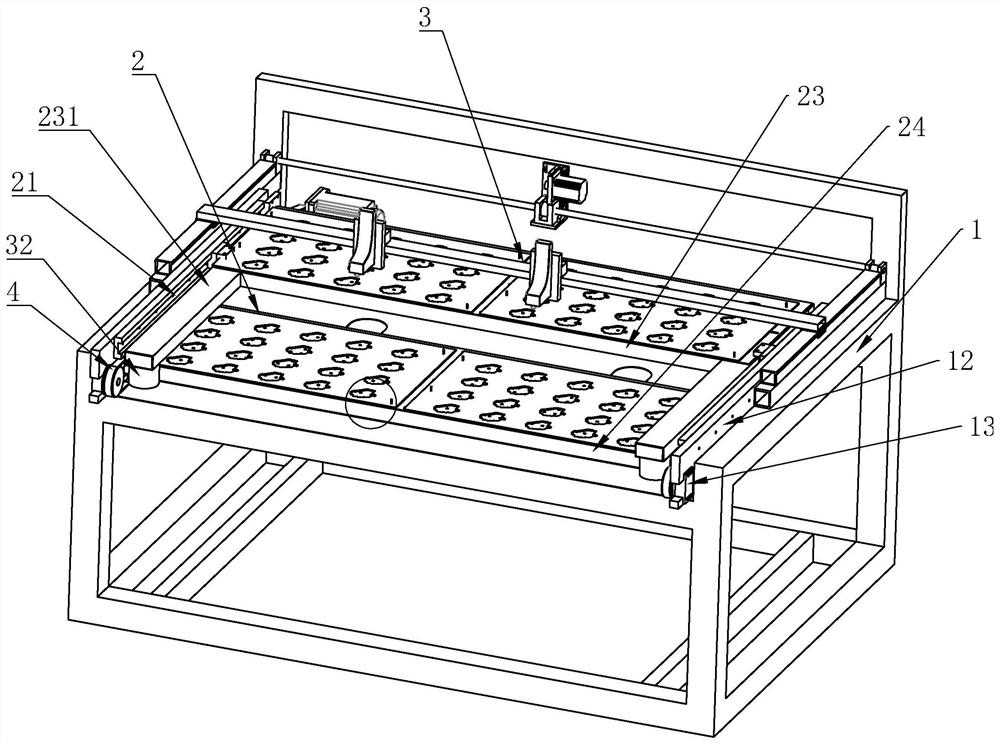

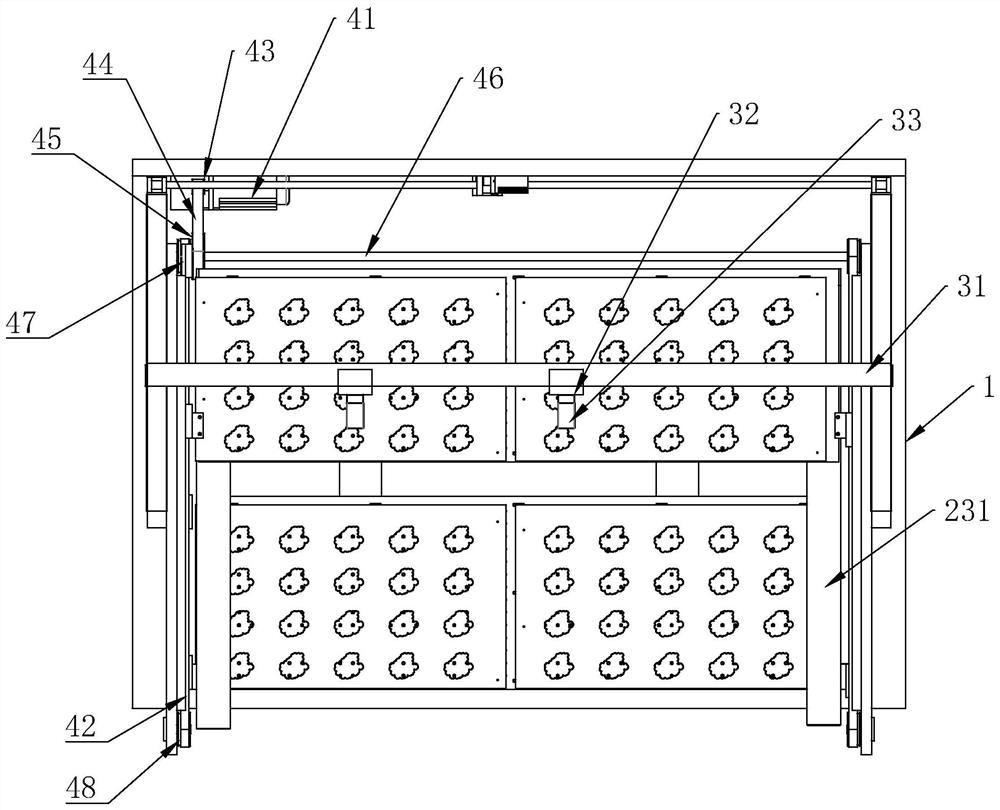

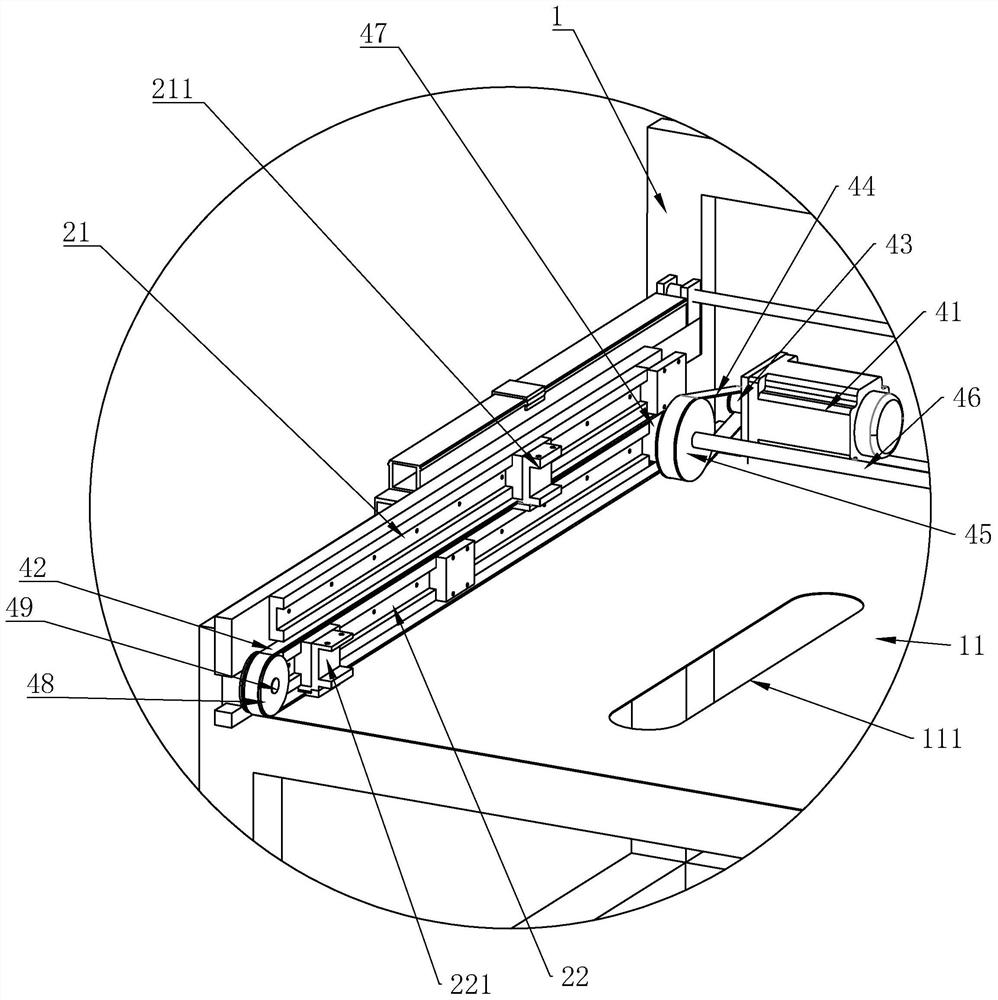

[0034] Referring to the accompanying drawings: a double-station automatic line-drawing machine for shoe materials in this embodiment includes a frame 1, a workbench 2 is arranged on the frame 1, and a line-drawing device 3 is arranged above the workbench 2, and the workbench 2. It includes two hollow structure vacuum adsorption plates arranged up and down on the frame 1. Several adsorption holes 25 are arranged on the upper surface of the vacuum adsorption plate. A template 26 is fixed on the vacuum adsorption plate. There are several holes hollowed out on the template 26. A positioning frame 27 for placing shoe materials, the positioning frame 27 exposes the adsorption hole 25, and the frame 1 is provided with a double-station switching mechanism, and the double-station switching mechanism includes a guide rail slider mechanism and Belt transmission mechanism 4, described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com