Micro pulse fluidized bed device applied to ultrafine powder fluidization

A pulsed flow, ultra-fine powder technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve problems such as poor response speed, complex gas supply system, and difficulty in adapting to micro-chemical systems, and achieve easy regulation and no movement. Components, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

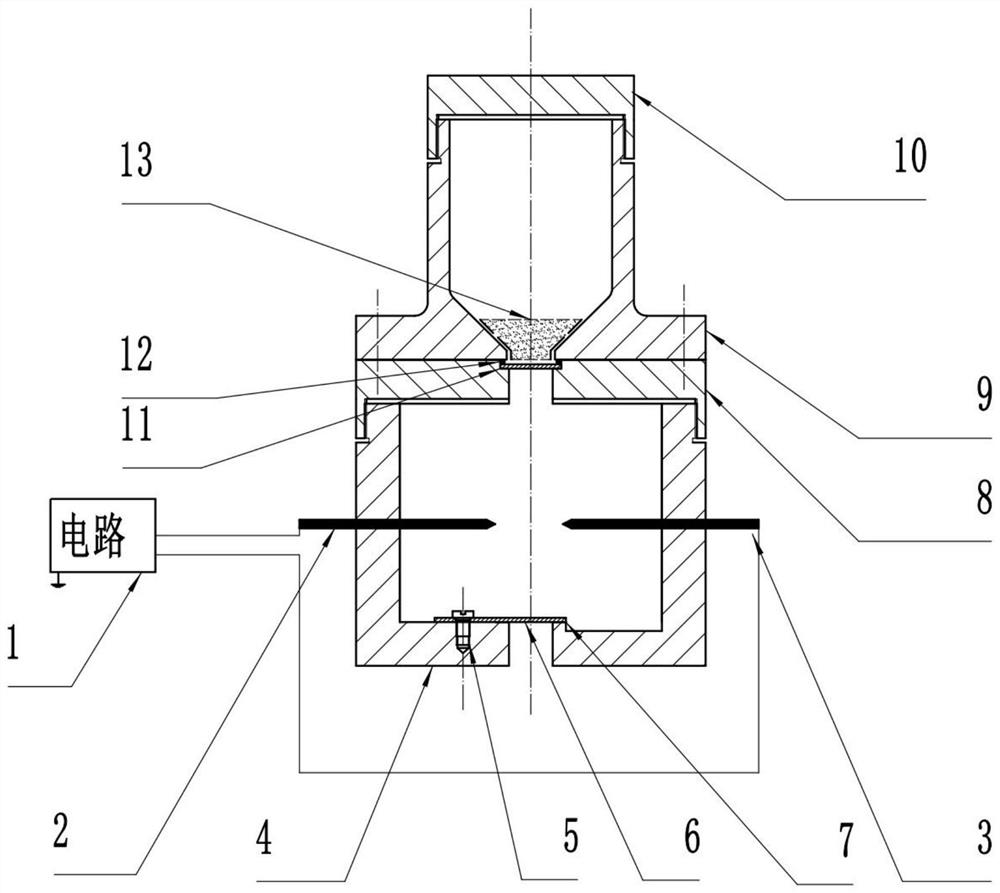

[0030] This embodiment relates to a micro-pulse fluidized bed device applied to ultrafine powder fluidization, and its structure is shown in the attached figure 1 As shown: the device includes: a circuit 1, a first discharge electrode 2, a second discharge electrode 3, a discharge cup 4 and a fluidized bed body 9;

[0031] in,

[0032] The circuit 1 is connected to the first discharge electrode 2 and the second discharge electrode 3;

[0033] The discharge cup 4 is provided with a discharge cup end cover 8, and the discharge cavity is formed by screw connection;

[0034] The first discharge electrode 2 and the second discharge electrode 3 are arranged in the middle of the discharge cup 4 .

[0035] There is a discharge gap between the first discharge electrode 2 and the second discharge electrode 3 .

[0036] The center of the bottom of the discharge cup 4 is provided with an air inlet.

[0037] The elastic sheet 6 is covered above the air inlet hole.

[0038] One end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com