Liquid storage barrel for optical grinding and polishing machine

A technology for optical grinding and polishing machines, which is applied to optical surface grinding machines, grinding/polishing equipment, and parts of grinding machine tools. Grinding, good filtering effect, avoiding the effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

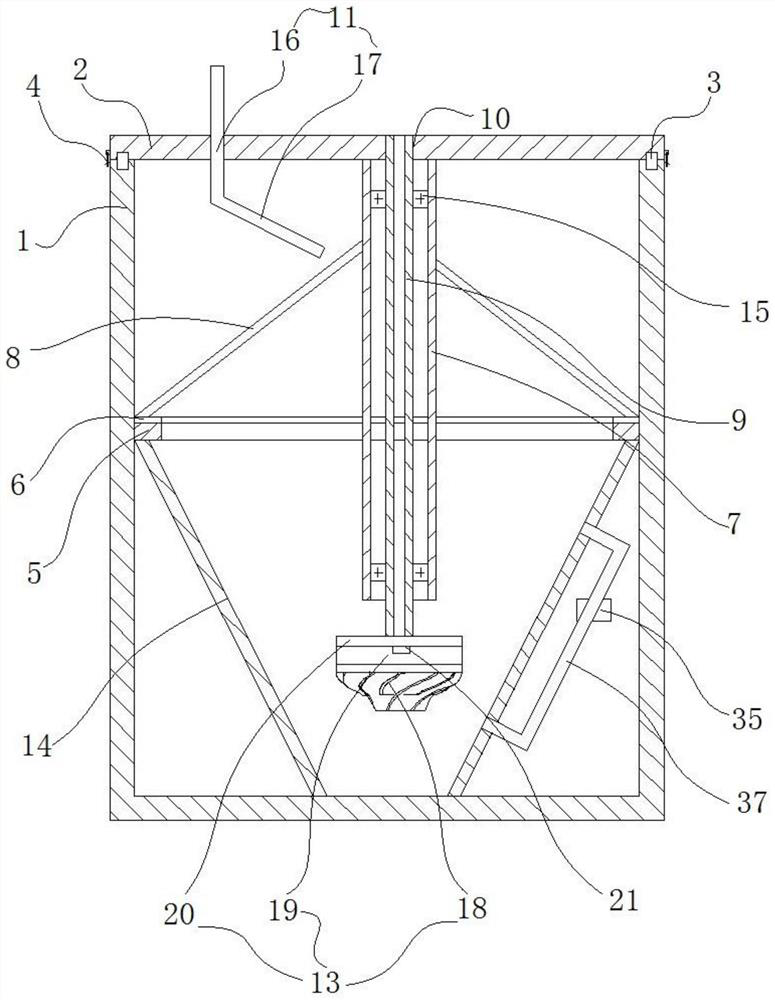

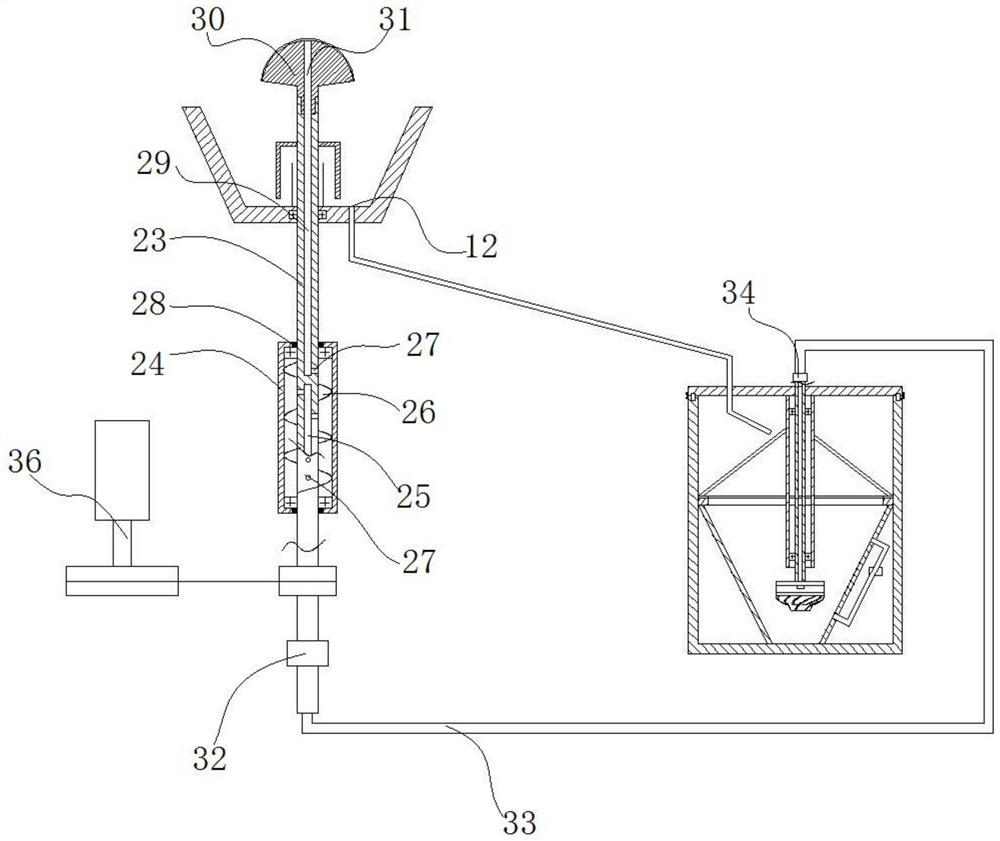

[0030] This embodiment discloses a liquid storage barrel for an optical grinding and polishing machine. 1 Realize detachable connection;

[0031] A boss 5 is arranged in the middle of the barrel body 1, a first sealing strip 6 is arranged on the boss 5, a rotating shaft jacket 7 is connected to the barrel cover 2, and a filter plate 8 in an umbrella-shaped structure is arranged on the outside of the rotating shaft jacket 7 , the filter plate 8 is provided with a spiral step, and the filter plate 8 is provided with a micro-filter hole; a hollow rotary rod 9 is provided through a bearing 15 in the rotary shaft outer cover 7, a liquid outlet 10 is provided on the barrel cover 2, and a hollow rotary rod 9 The bung 2 can be stretched out from the outlet hole 10, and a return pipe 11 is also arranged on the bung 2, and the return pipe 11 is used to be connected with the polishing fluid return passage 12 of the polishing machine; Suction device connection;

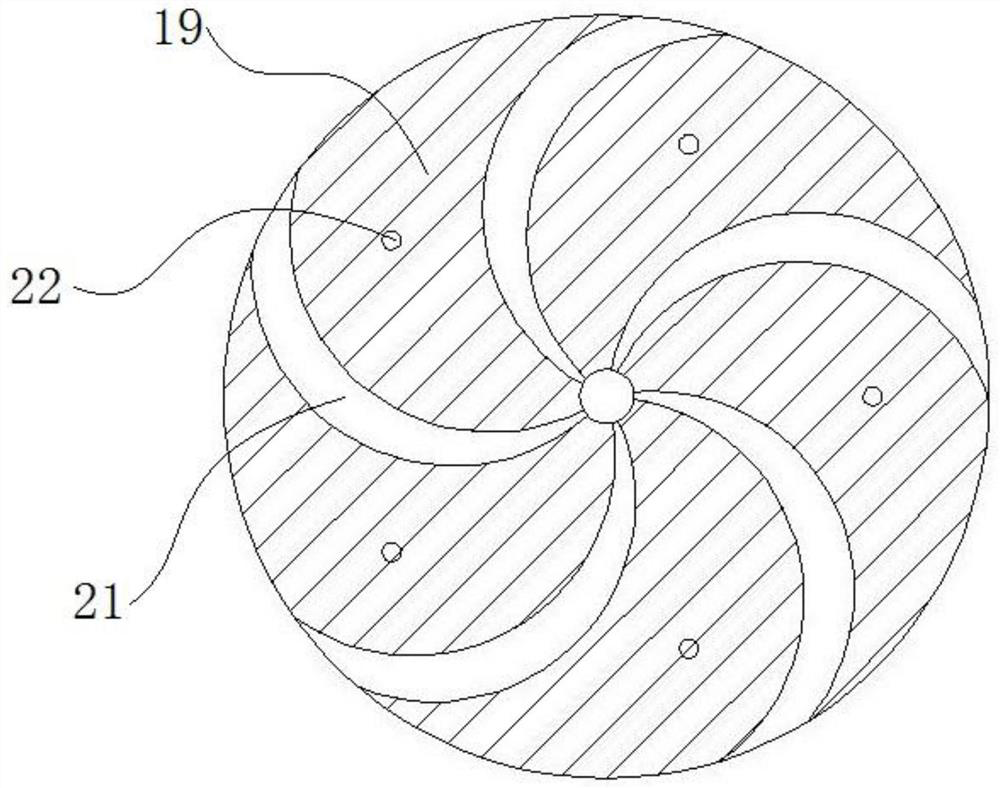

[0032] An impeller asse...

Embodiment 2

[0048] This embodiment is further optimized on the basis of Embodiment 1. In this embodiment, a liquid level detection device 35 is provided on the bucket body 1, and the liquid level detection device 35 is connected with an alarm.

[0049] It is further defined that the liquid level detection device 35 is a liquid level detection sensor; in this way, it can give an alarm in time when the polishing liquid is lower than the preset liquid level line, so as to avoid dry grinding due to insufficient polishing liquid.

[0050] In this embodiment, the liquid level detection sensor includes a light source generator and a light source receiver, and a communication pipe 37 is arranged on the side wall of the water guide cylinder 14. The light source generator and light source receiver are arranged on the communication pipe 37, and the light source generator emits ultraviolet light. light, when there is polishing liquid in the connecting pipe 37, the ultraviolet light cannot pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com