Supercritical fluid foaming method of thermoplastic elastomer and its products and applications

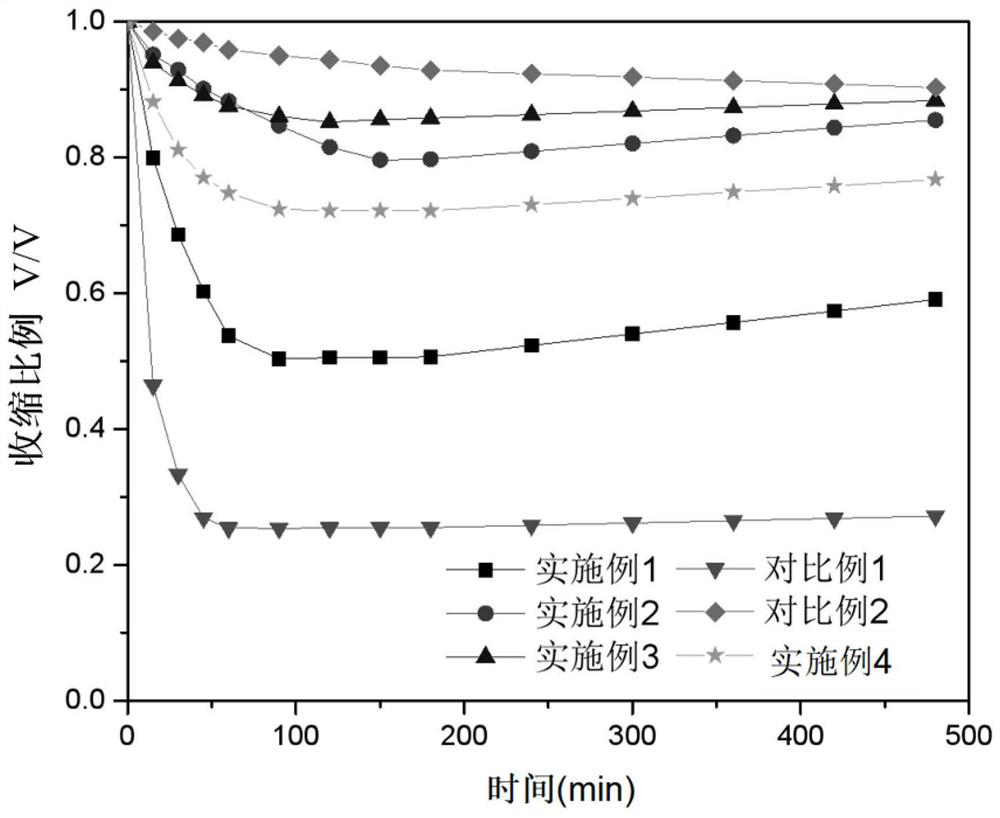

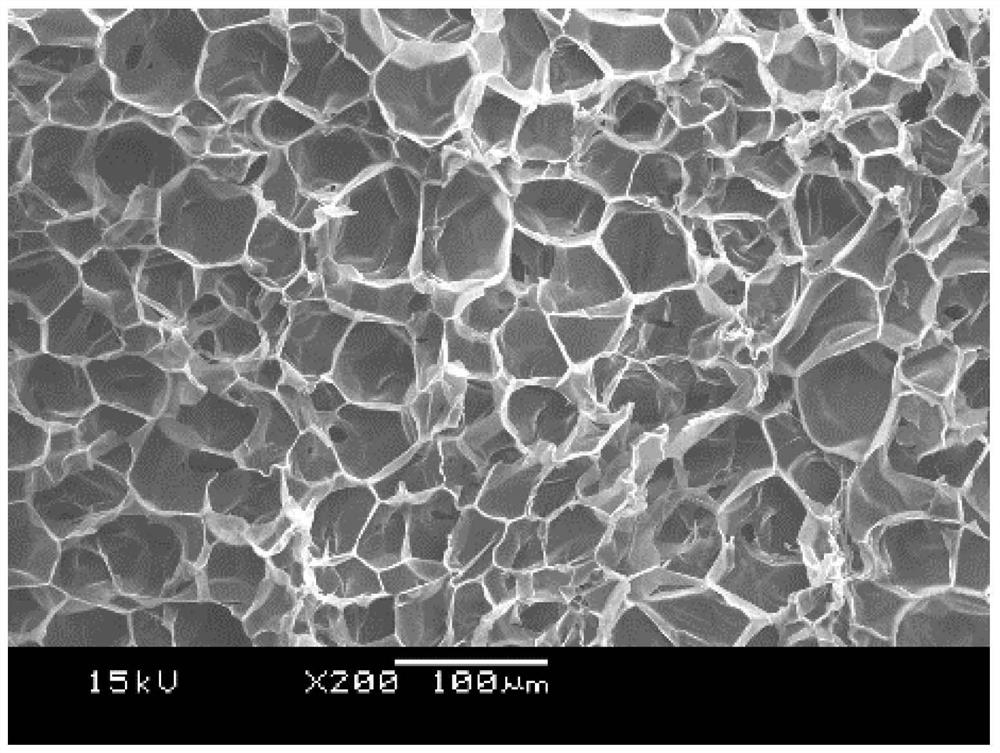

A thermoplastic elastomer and supercritical fluid technology, which is applied in the field of polymer preparation, can solve the problems of thermoplastic elastomer foaming materials such as decreased mechanical properties, large shrinkage rate, and complicated process, and achieves short saturation time, small shrinkage rate, and process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] The preparation of embodiment 1TPU foam material

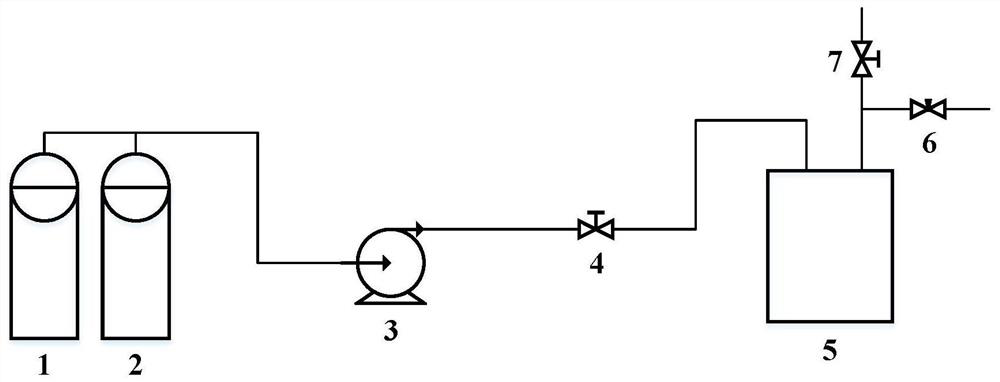

[0090] (1) Place the TPU sheet in the mold cavity 5, and heat the mold cavity 5 with programmed temperature control at a heating rate of 10°C / min to a foaming temperature of 150°C;

[0091] (2) Open the first ball valve 4, start the syringe pump 3, and supercritical N 2 Inject into the mold cavity 5, the cavity pressure after injection is 5MPa, then supercritical CO 2 Inject in the mold cavity 5, the mold cavity pressure is 15MPa after injecting, close the first ball valve 4, keep supercritical state 90min; Wherein, N 2 and CO 2 The pressure ratio is 1:2;

[0092] (3) Open the second ball valve 7 to quickly relieve the pressure on the mold cavity 5 at a rate of 400 MPa / s to obtain a TPU microcellular foaming material.

Embodiment 2

[0093] The preparation of embodiment 2TPU foam material

[0094] In the step (2) of embodiment 2, supercritical N 2 Inject into cavity 5, the cavity pressure after injection is 10MPa, wherein, N 2 and CO 2 The pressure ratio is 2:1; Other process conditions are all with embodiment 1.

Embodiment 3

[0095] The preparation of embodiment 3TPU foam material

[0096] (1) Place the TPU sheet in the mold cavity 5, and heat the mold cavity 5 with programmed temperature control at a heating rate of 10°C / min to a foaming temperature of 150°C;

[0097] (2) Open the first ball valve 4, start the syringe pump 3, and supercritical N 2Inject into the mold cavity 5, the cavity pressure after injection is 10MPa, and then the supercritical CO 2 Inject in the mold cavity 5, the mold cavity pressure is 15MPa after injecting, close the first ball valve 4, keep the supercritical state 10min; Wherein, N 2 and CO 2 The pressure ratio is 2:1;

[0098] (3) Open the needle valve 6, slowly release the pressure to the mold cavity 5 to 0MPa, the pressure relief rate is 0.03MPa / s, and close the needle valve 6;

[0099] (4) Open the first ball valve 4, start the syringe pump 3, and supercritical N 2 Inject into the mold cavity 5, the cavity pressure after injection is 10MPa, and then the supercrit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com