A glass canned food packaging and capping line

A technology for canned food and glass jars, applied in the field of glass jar packaging and capping machinery, can solve the problems of putting in, the glass jar cannot be centered, the glass jar slipping, etc., and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

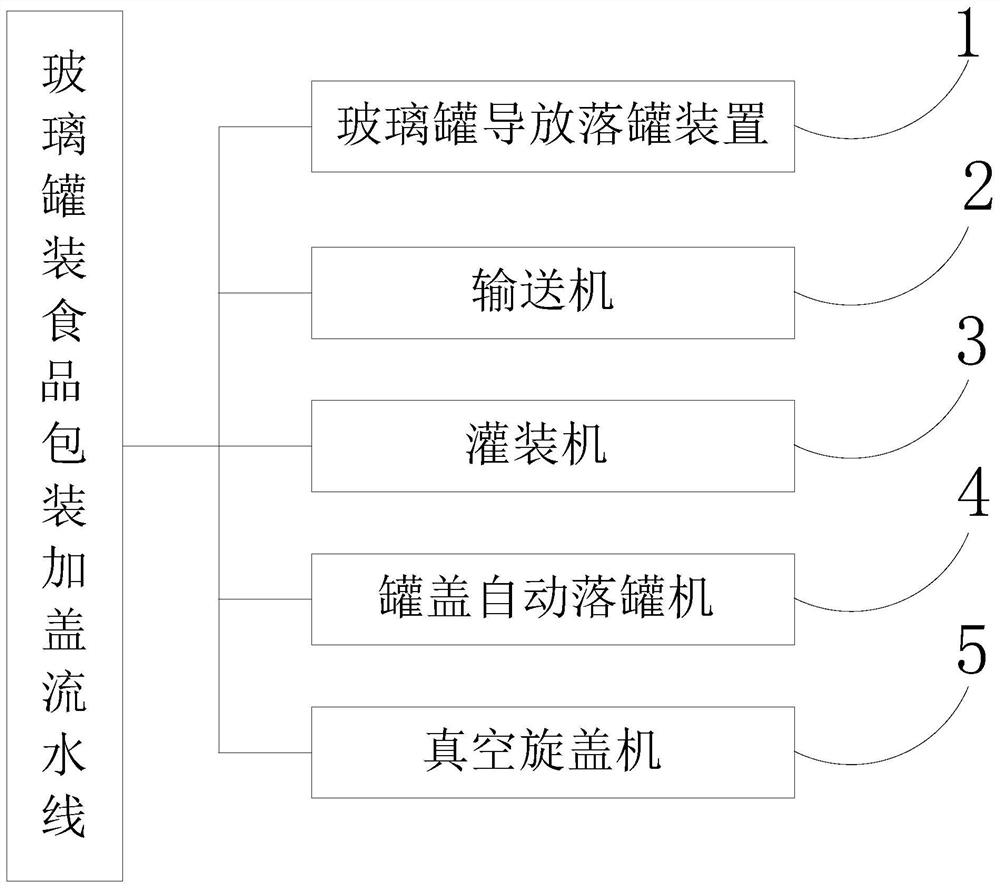

[0036] see Figure 1-9 , the present invention provides a technical solution for a glass canned food packaging and capping assembly line: the present invention adopts the following technical solution to achieve: a glass canned food packaging and capping assembly line, the structure of which includes a glass can guiding and dropping device 1, a conveying Machine 2, filling machine 3, can lid self-dropping machine 4, vacuum capping machine 5, and the conveyor 2 is provided with a glass jar guide release device 1, filling machine 3, and can lid self-falling cap Machine 4, vacuum capping machine 5.

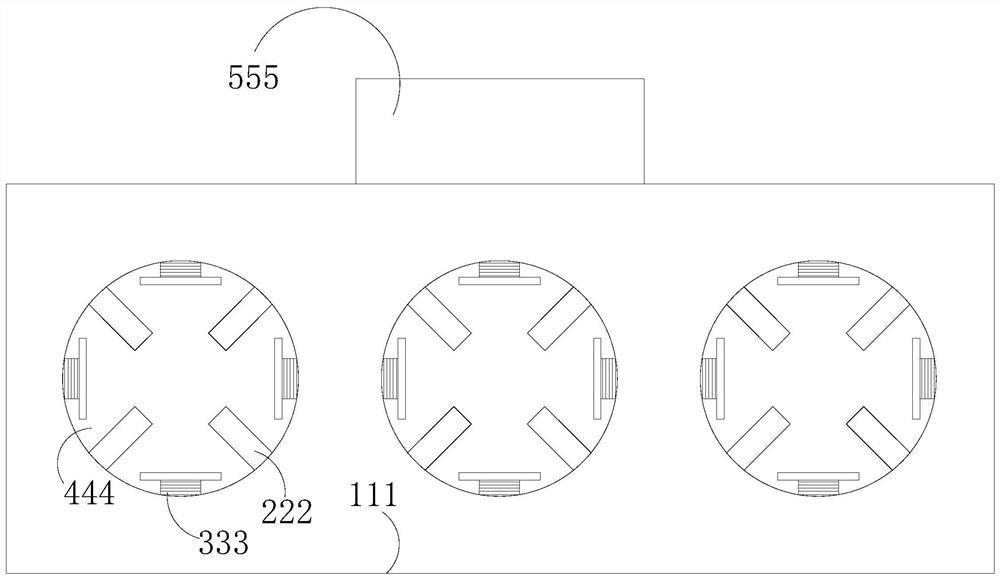

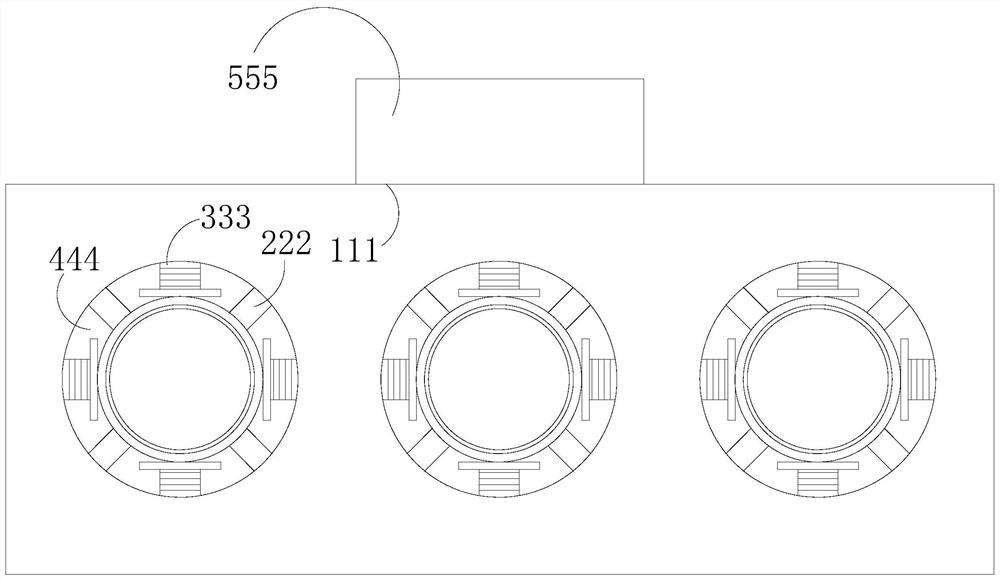

[0037] The glass jar guide release device 1 includes a glass jar guide rack 111, a pressure air guide mechanism 222, a glass jar limit mechanism 333, a glass jar insertion channel 444, and a lifting device 555. A glass jar guide rack 111 is installed, and the glass jar guide rack 111 can be lifted and lowered by a lifting device 555. The glass jar guide rack 111 is provided with thre...

Embodiment 2

[0042] see Figure 1-9 , the present invention provides a technical solution for a glass canned food packaging and capping assembly line: the present invention adopts the following technical solution to achieve: a glass canned food packaging and capping assembly line, the structure of which includes a glass can guiding and dropping device 1, a conveying Machine 2, filling machine 3, can lid self-dropping machine 4, vacuum capping machine 5, and the conveyor 2 is provided with a glass jar guide release device 1, filling machine 3, and can lid self-falling cap Machine 4, vacuum capping machine 5.

[0043] The glass jar guide release device 1 includes a glass jar guide rack 111, a pressure air guide mechanism 222, a glass jar limit mechanism 333, a glass jar insertion channel 444, and a lifting device 555. A glass jar guide rack 111 is installed, and the glass jar guide rack 111 can be lifted and lowered by a lifting device 555. The glass jar guide rack 111 is provided with thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com