Rubber material for inner liner of explosion-proof tire and preparation method thereof

A technology of run-flat tires and airtight layers, which is applied to special tires, tire parts, transportation and packaging, etc., and can solve problems such as scrapping of run-flat tires and cracks in the airtight layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

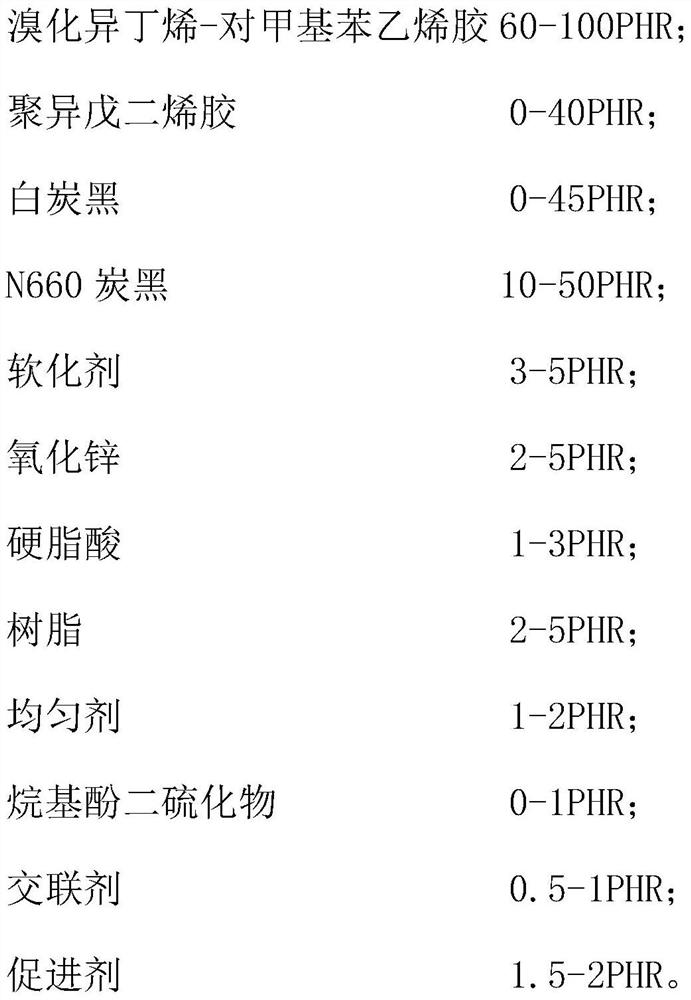

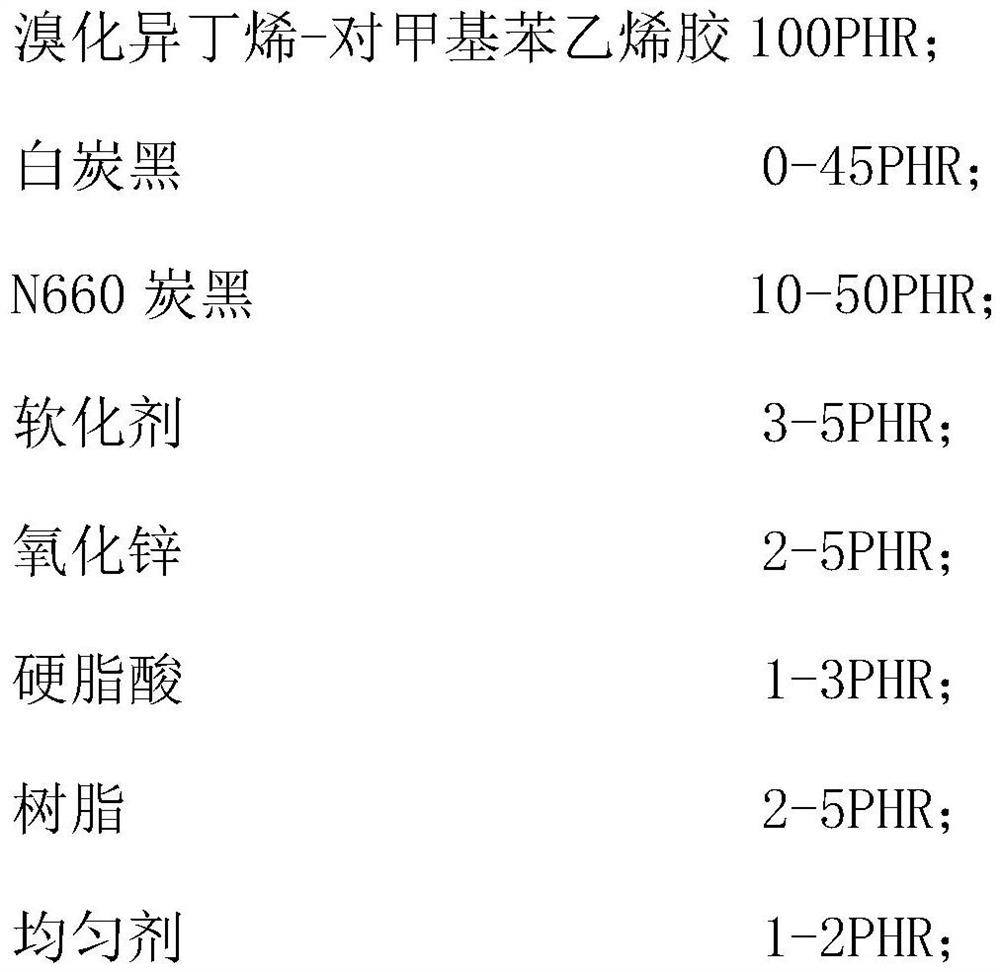

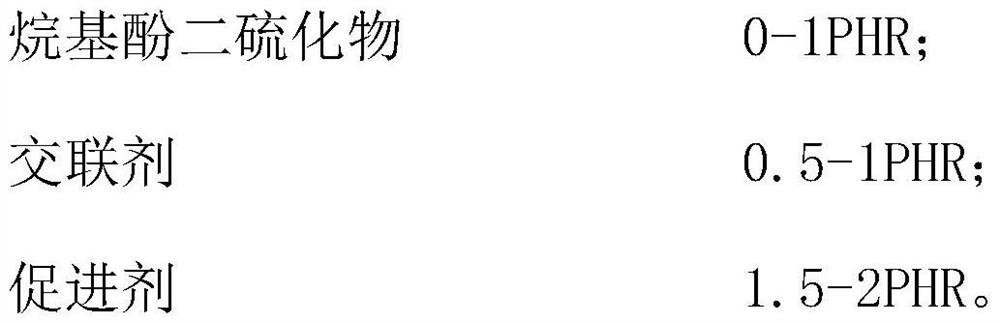

Method used

Image

Examples

Embodiment 1

[0027] Brominated isobutylene-p-methylstyrene glue 80PHR, polyisoprene glue 20PHR, low specific surface area silica (PET<100) 40PHR, carbon black N660 15PHR, naphthenic oil 4PHR, zinc oxide 4PHR, stearic acid 2PHR, carbon five resin 3PHR, RH100 2PHR, alkylphenol disulfide 0.8PHR, sulfur 0.9PHR, accelerator DM 1.3PHR, accelerator TT 0.2PHR.

[0028] Put the polyisoprene glue into the internal mixer together with brominated isobutylene-p-methylstyrene glue, stearic acid, tackifier carbon five resin, and leveling agent RH100 according to the conventional conditions; about 25 seconds The latter two rubbers have been basically broken, and then put in low specific surface area white carbon black and N660 carbon black to 90 °C, add softener naphthenic oil to 115 °C, and discharge when the upper top bolt is cleaned to 145 °C; park for at least After 4 hours until the temperature of the film drops to room temperature, put it into the internal mixer together with zinc oxide, accelerator...

Embodiment 2

[0030] Brominated isobutylene-p-methylstyrene glue 100PHR, low specific surface area silica (PET<100) 45PHR, carbon black N660 10PHR, environmentally friendly aromatic oil 4PHR, zinc oxide 5PHR, stearic acid 2.5PHR, carbon nine resin 5PHR, Leveling agent CJ4001PHR, insoluble sulfur 1PHR, accelerator DM 1.25PHR, accelerator TT 0.3PHR.

[0031] First put brominated isobutylene-p-methylstyrene rubber, stearic acid, C9 resin, and leveling agent CJ400 into the internal mixer together; after about 25 seconds, the two rubbers have been basically broken, and then put in low specific surface area white carbon black and N660 carbon black to 90°C, put in environmentally friendly aromatic hydrocarbon oil to 115°C, clean the top bolt to 145°C, and discharge; park for at least 4 hours until the film temperature drops to room temperature, and then mix with zinc oxide, accelerator (DM, TT) and insoluble sulfur are put into the internal mixer together, and when it is about 80°C, lift the top b...

Embodiment 3

[0033] Brominated isobutylene-p-methylstyrene glue 90PHR, polyisoprene glue 10PHR, low specific surface area silica (PET<100) 35PHR, carbon black N660 20PHR, naphthenic oil 4PHR, zinc oxide 4PHR, stearic acid 2PHR, carbon five resin 3PHR, RH100 2PHR, alkylphenol disulfide 0.8PHR, sulfur 0.9PHR, accelerator DM 1.3PHR, accelerator TT 0.2PHR.

[0034] Put the polyisoprene glue into the internal mixer together with brominated isobutylene-p-methylstyrene glue, stearic acid, tackifier carbon five resin, and leveling agent RH100 according to the conventional conditions; about 25 seconds The latter two rubbers have been basically broken, and then put in low specific surface area white carbon black and N660 carbon black to 90°C, add softener naphthenic oil to 115°C, and discharge when the upper top bolt is cleaned to 145°C; park for at least After 4 hours until the temperature of the film drops to room temperature, put it into the internal mixer together with zinc oxide, accelerators (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com