Slotting type wind turbine blade device and slotting method thereof

A technology of wind turbine blades and blade bodies, which is applied in the direction of wind engines, wind engines, and wind engine control in the same direction as the wind. Pressure, the effect of increasing the positive pressure surface pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

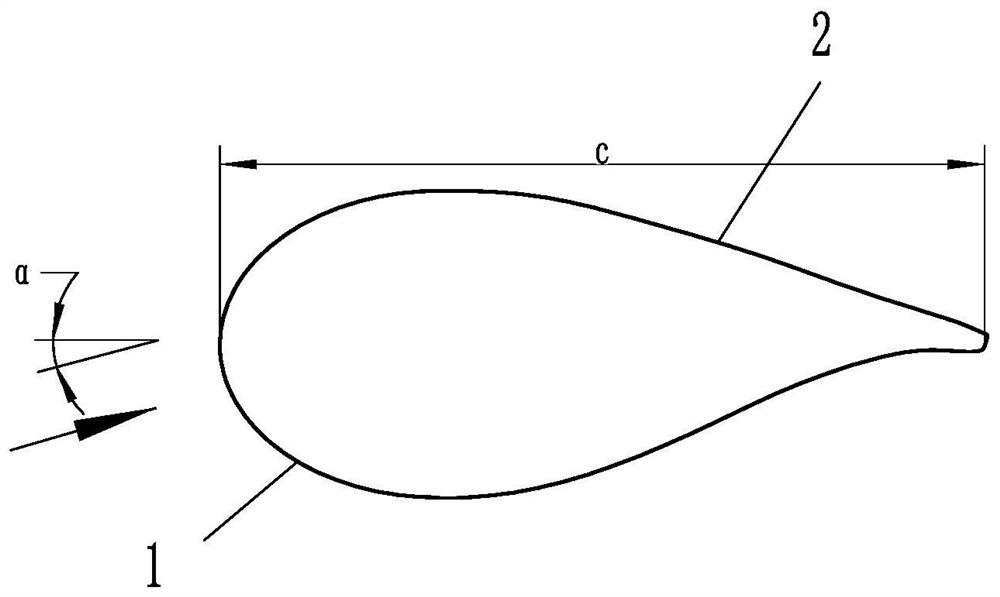

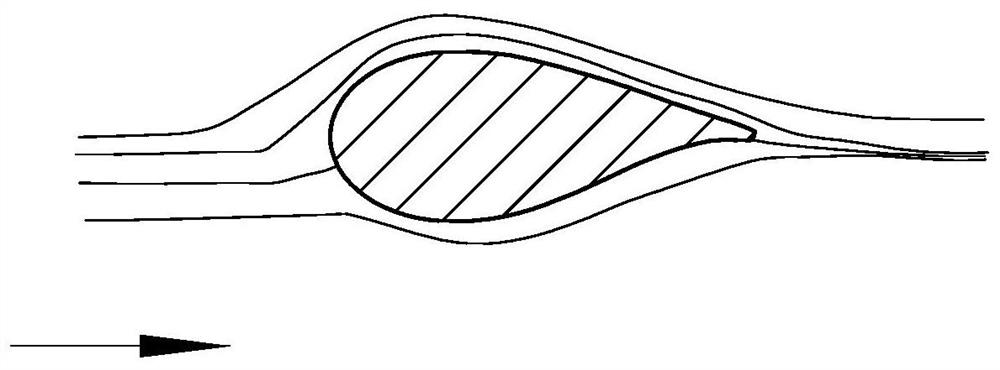

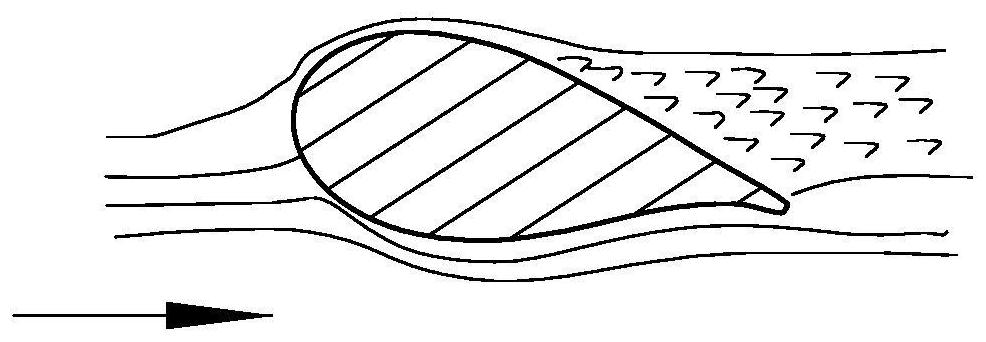

[0042] Such as Figure 6 , Figure 7 and Figure 10 As shown, it is a slotted wind turbine blade device, including a blade body, the blade body includes a positive pressure surface 1 and a back pressure surface 2, and a gap 3 connecting the positive pressure surface 1 and the back pressure surface 2 is provided inside the blade body, After the gas flows into the gap 3 from the positive pressure surface 1, the gas flows out from the back pressure surface 2. The gap 3 includes an air inlet 11 on the positive pressure surface 1 and an air outlet 21 on the back pressure surface 2 , and a surge tank 32 is also provided in the gap 3 . The air inlet 11 and the air outlet 21 are respectively connected to the surge tank 32 through the pipeline 31 , and the tapered surfaces 22 gradually approaching inward are respectively provided between the air inlet 11 and the pipeline 31 and between the air outlet 21 and the pipeline 31 . The tapered surface 22 is a corrugated surface, which can ...

Embodiment 2

[0044] Such as Figure 11 As shown, the difference between Embodiment 2 and Embodiment 1 is that: the air inlet 11 is an intermittent opening, and the different openings are collected into the same pipe 31 through the tapered surface 22 and connected to the surge tank 32 .

Embodiment 3

[0046] Such as Figure 12 As shown, the difference between Embodiment 3 and Embodiment 1 is that: the air inlet 11 is provided with two channels arranged at intervals, and the two air inlets 11 communicate with the surge tank 32 through different pipes 31 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com