Wind generator with rotor wind path

A wind power generator and rotor technology, applied in wind power generation, electromechanical devices, electrical components, etc., can solve the problems of large axial temperature difference of the rotor magnetic poles and insufficient cooling wind force of the rotor magnetic poles, so as to reduce the axial temperature difference and improve the cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

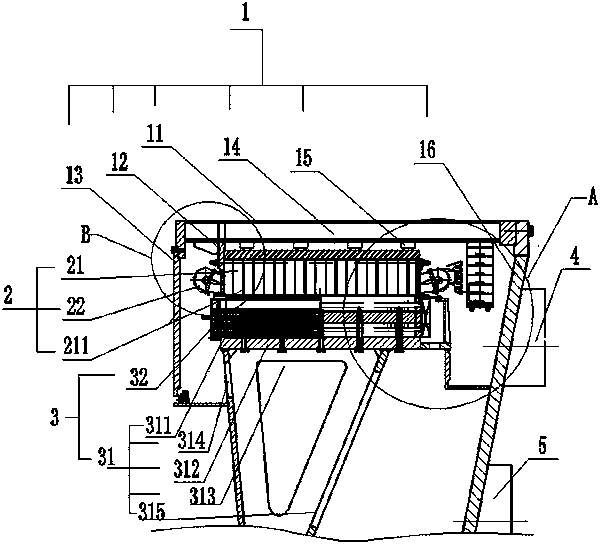

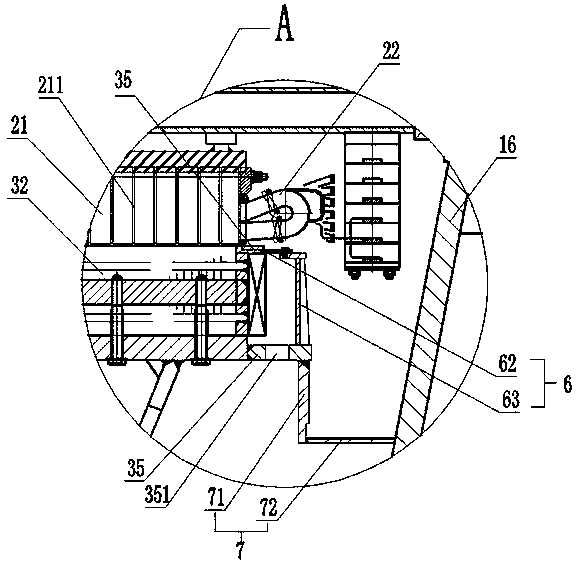

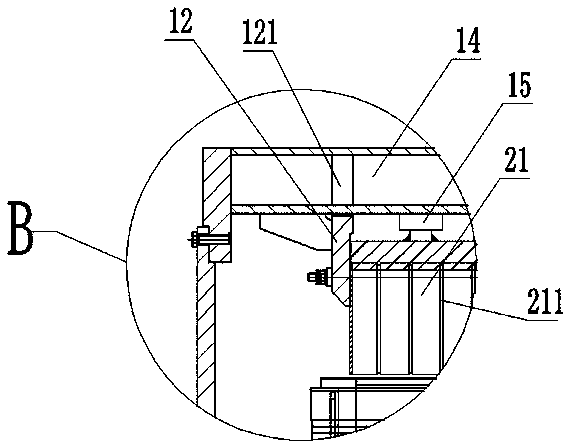

[0029] Such as Figure 1-3As shown, a wind power generator with a rotor air path, the power is 2.2MW, including base 1, stator 2, rotor 3, air inlet 4 and air outlet 5, the diameter of air inlet 4 is 452mm, and the diameter of air outlet 5 is 452mm The rotor 3 includes a rotor bracket 31 and a rotor pole 32, and the rotor bracket 31 includes a rotor support cylinder 311, a first conical plate 313 and a second conical plate 314 connected with the rotor support cylinder 311; the first conical plate 313 and the second conical plate 314; Conical plate ventilation holes 331 are provided on the two conical plates 314, and the sizes of the conical plate ventilation holes 331 on the first conical plate 313 and the second conical plate 314 are different; the non-driving end of the rotor support cylinder 311 It is connected with the rotor support cylinder 35; rotor support ventilation holes 351 are arranged on the side wall of the rotor support cylinder 35, and the rotor support ventila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com