Two-dimensional surface heat flux density real-time online measuring device and method

A heat flux density and measuring device technology, applied in measuring devices, measuring heat, calorimeters, etc., can solve problems such as difficult to solve heat conduction inverse problems, difficult to output in real time, time-consuming calculations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with specific drawings and embodiments.

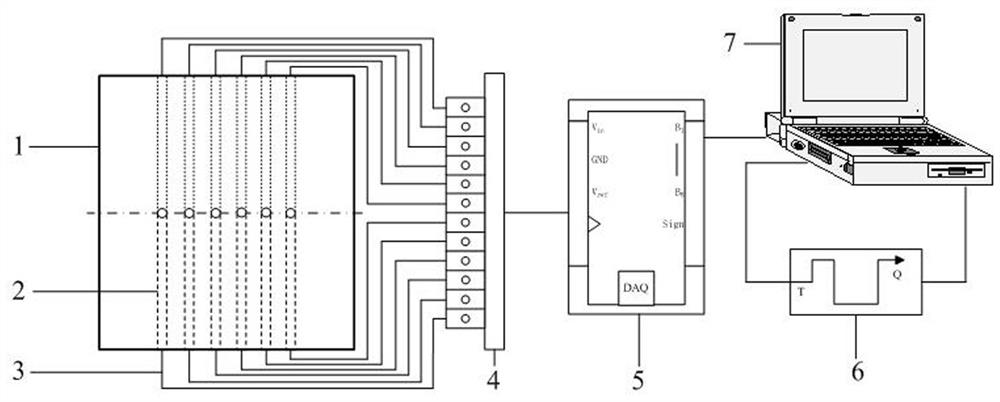

[0075] Such as figure 1 As shown: In order to solve the problem of online monitoring and measurement of heat flux on the surface of thermal conversion equipment such as boilers and internal combustion engines, the present invention includes a substrate 1 and a substrate temperature sensor capable of monitoring the temperature of multiple points of the substrate 1. The substrate temperature sensor is collected through data The board 5 is electrically connected to the measurement control computing device 7, and the measurement control computing device 7 can monitor the multi-point temperature of the substrate 1 through the data acquisition board 5 to collect synchronously; the measurement control computing device 7 obtains the multi-point temperature of the substrate 1 After obtaining the temperature value, the surface heat flux density of the substrate 1 is calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com