How to make a mems microphone

A manufacturing method and microphone technology, applied in the direction of sensors, electrostatic transducers, microphones, electrical components, etc., can solve problems such as metal residues and device defects, and achieve the effects of avoiding residues, improving product yield, and increasing photomask costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

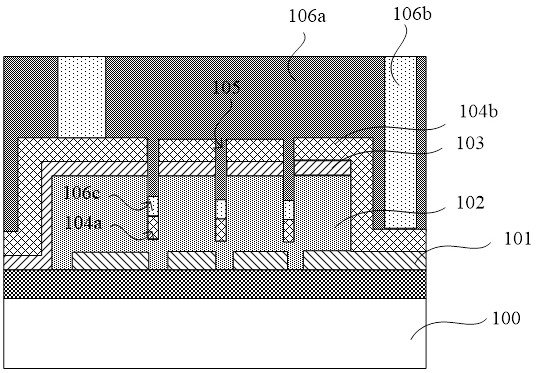

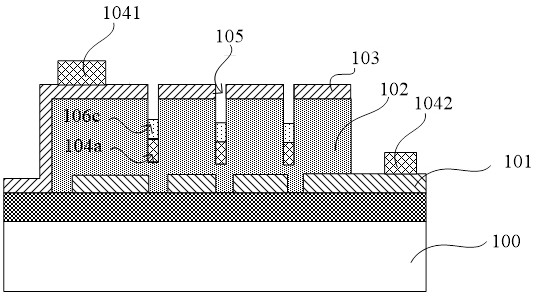

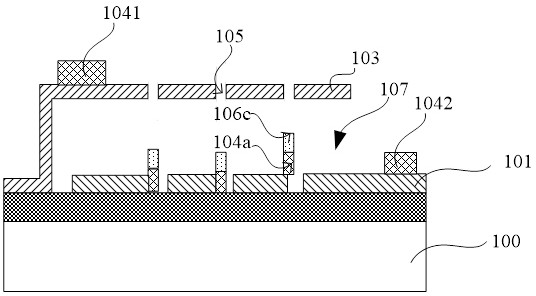

[0028] An existing manufacturing method of a MEMS microphone comprises the following steps:

[0029] First, please refer to figure 1 After making the lower pole plate 101 on the substrate 100, the sacrificial layer 102 and the upper pole plate 103 will be fabricated, and a number of acoustic holes 105 will be formed. Layer 102.

[0030] Then, please continue to refer to figure 1 , a metal layer with a certain thickness will be deposited on the upper pole plate 103 and the sacrificial layer 102 exposed by the upper pole plate 103 and the lower pole plate 101, and a part 104b of the metal layer will cover the surfaces of the upper pole plate 103 and the lower pole plate 101 , the other part 104a will be filled in the acoustic hole 105.

[0031] Next, please continue to refer to figure 1 , forming a photoresist layer on the metal layer, the photoresist layer will fill the acoustic hole 105, and partially expose the photoresist layer. After exposure, the photoresist layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com