Processing technology of calcined concha haliotidis and quality evaluation method of processing technology

A technology for calcining Cassia and processing technology, applied in the field of traditional Chinese medicine calcination, can solve the problems of temperature, time, crushing particle size, laying thickness and other process parameters that are not clearly specified, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

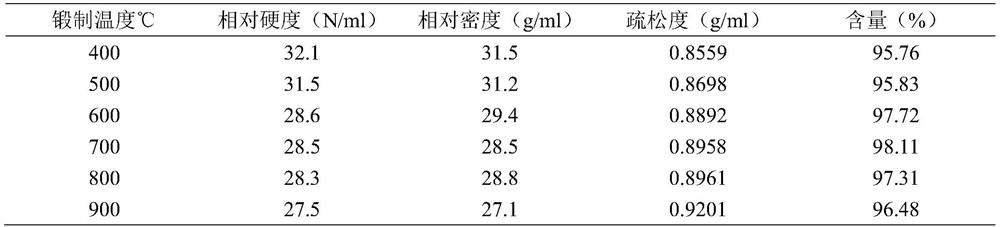

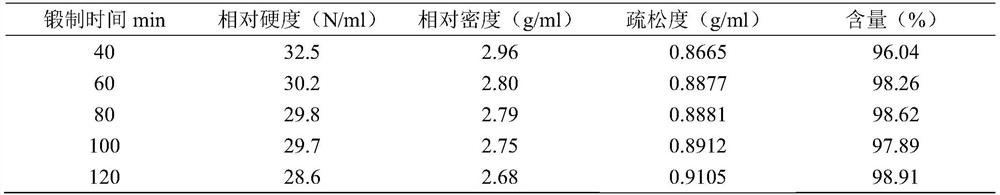

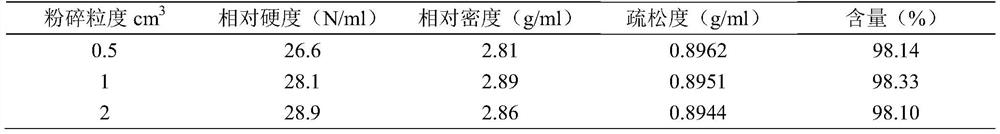

Method used

Image

Examples

Embodiment 1

[0051] A kind of processing technology of calcined cassia, comprising the following steps: taking stone cassia, crushing it into 8cm 3 Small pieces of particle size are placed in a crucible to lay a mat to a thickness of 2 cm, calcined at 700 ° C for 80 minutes, and taken out to obtain calcined Cassia.

Embodiment 2

[0053] A kind of processing technology of calcined cassia, comprising the following steps: taking stone cassia, crushing it into 5cm 3 Small pieces of particle size are placed in a crucible to lay a mat to a thickness of 1 cm, calcined at 600 ° C for 100 min, and taken out to obtain calcined Cassia.

Embodiment 3

[0055] A kind of processing technology of calcined cassia, comprising the following steps: taking stone cassia, crushing it into 1cm 3 Small pieces of particle size are placed in a crucible to lay a mat to a thickness of 4cm, calcined at 800°C for 60min, and taken out to obtain calcined Cassia.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com