Insert part laser solder ball device and welding method

A laser welding and plug-in technology, applied in tin feeding devices, auxiliary devices, welding equipment and other directions, can solve the problems of wasting time, energy and manpower, quality problems, welding defects, etc., to improve efficiency, high production efficiency, High welding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

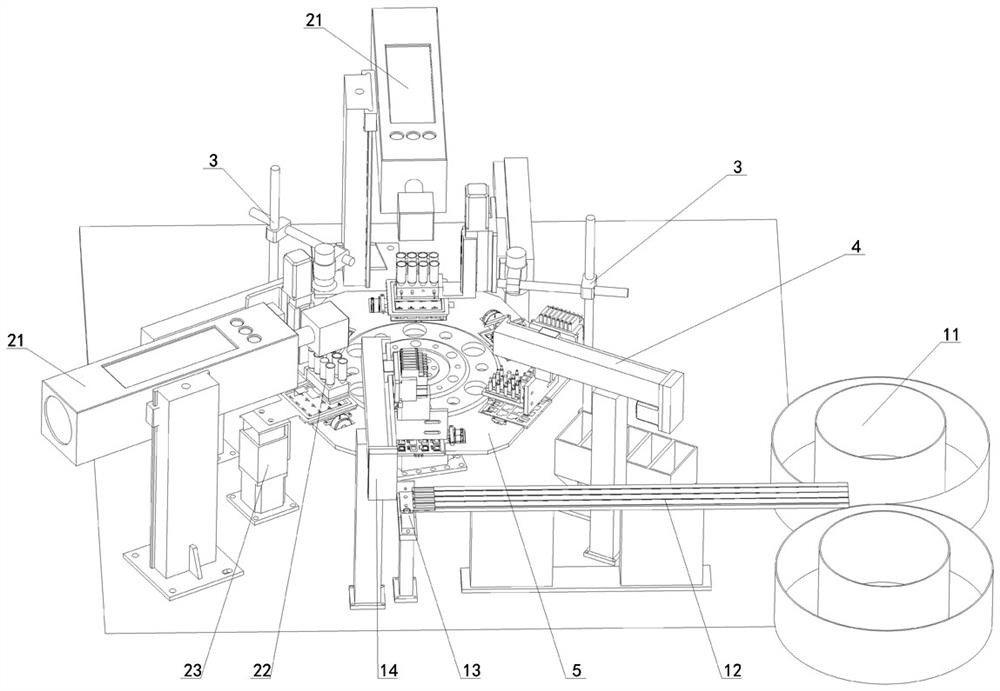

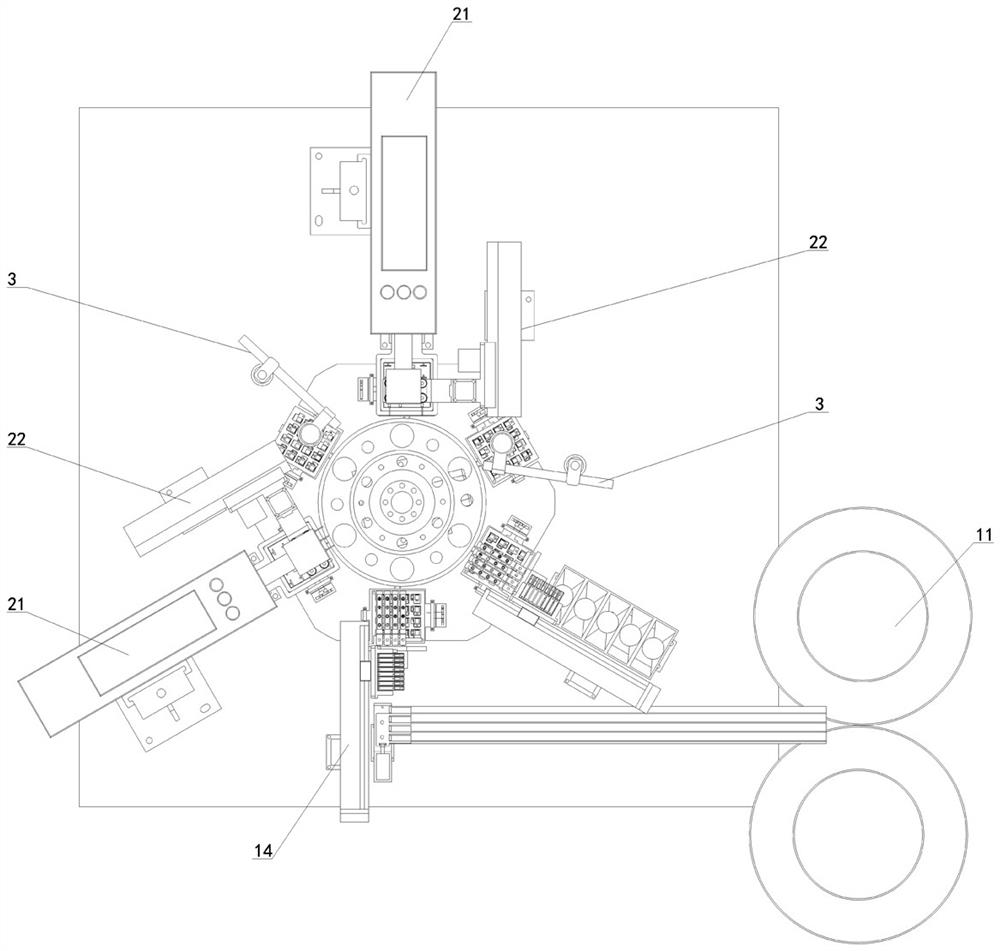

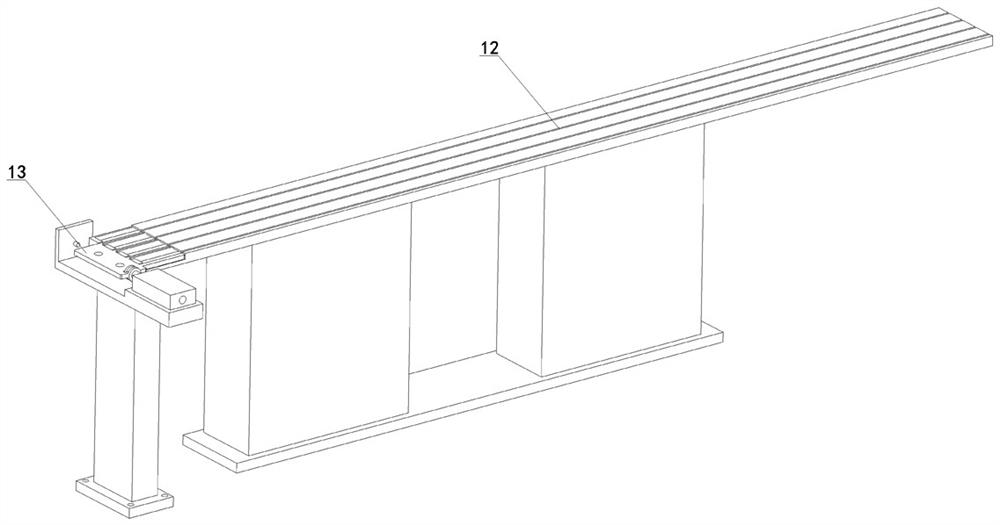

[0067] In order to make the purpose, technical scheme and advantages of the present invention more clear, the following will be combined with the appended figure 1 ~ attached Figure 18 , to describe the present invention in more detail.

[0068] The laser solder ball device for the connector provided by the present invention includes a feeding part 1, a laser welding part 2, a visual inspection part 3, a feeding part 4 and a turntable part 5; the laser welding part 2 includes a nine-ball laser welding part and a ten-ball laser welding part Laser welding section; feeding section 1, nine-ball laser welding section, visual inspection section 3, ten-ball laser welding section, visual inspection section 3 and unloading section 4 are evenly arranged around the turntable section 5 in the form of a hexagonal array The turntable part 5 includes a turntable 51 and a turntable base 53, and the turntable 51 is arranged on the top of the turntable base 53 in a rotatable manner; the turnt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com