Stir friction welding method for dissimilar metal lap joint

A friction stir welding and metal plate technology, which is applied in metal processing equipment, welding/welding/cutting items, welding equipment, etc., can solve the problems of stirring needle wear, poor joint shape, low joint performance, etc., and achieve beautiful weld shape , Reduce the embrittlement of the joint and improve the performance of the joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

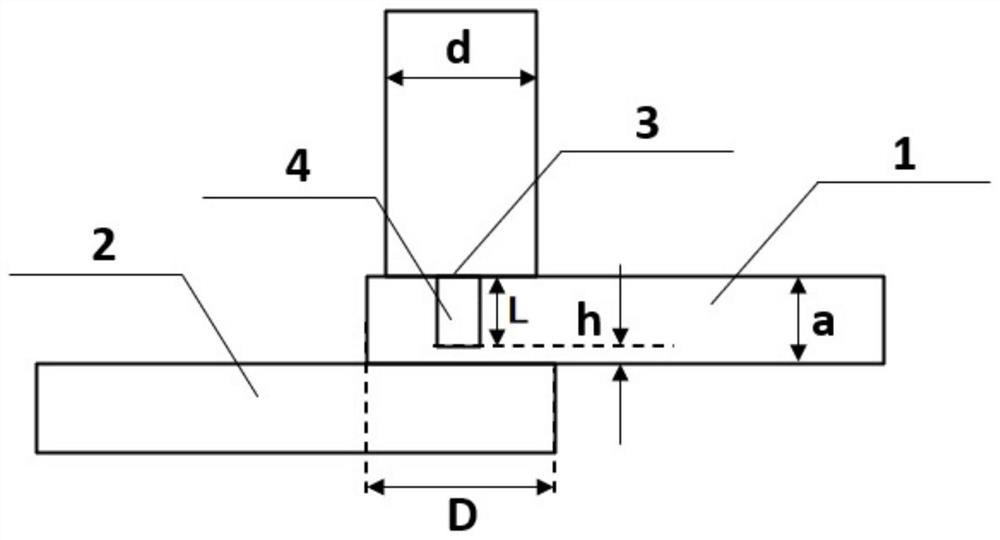

[0027] The welding method of the present invention is mainly aimed at lap joints welded by dissimilar materials. By controlling the distance between the needle portion of the stirring head and the upper surface of the lapped lower plate, and at the same time ensuring the pressure of the stirring head on the test plate, the gap between the upper plate and the lower plate is ensured. A certain amount of intermetallic compound and diffusion layer or a single intermetallic compound or a single diffusion layer can be produced, so as to realize the effective connection of lap joints and obtain lap joints of dissimilar metals with beautiful weld shape and excellent joint performance.

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

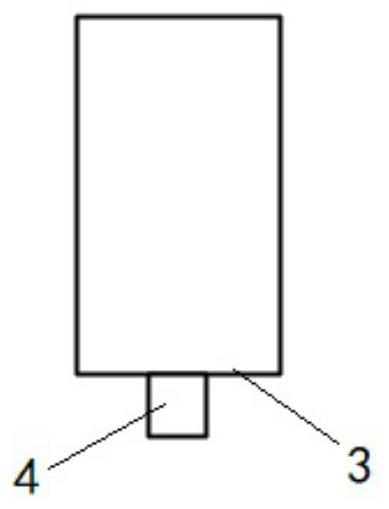

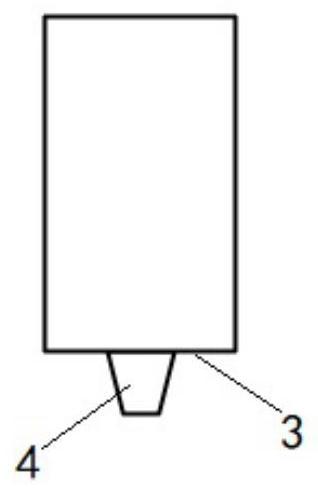

[0029] Such as figure 1 As shown, the first metal plate 1 and the second metal plate 2 overlap up and down, wherein the hardness of the first metal plate 1 is smaller than that of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com