Self-adaptive dry adsorption-desorption functional pneumatic flexible gripper

An adaptive and functional technology, applied in the field of robotics, can solve problems such as the inability to grasp large-mass objects, application limitations of pneumatic flexible grippers, and low flexible grippers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

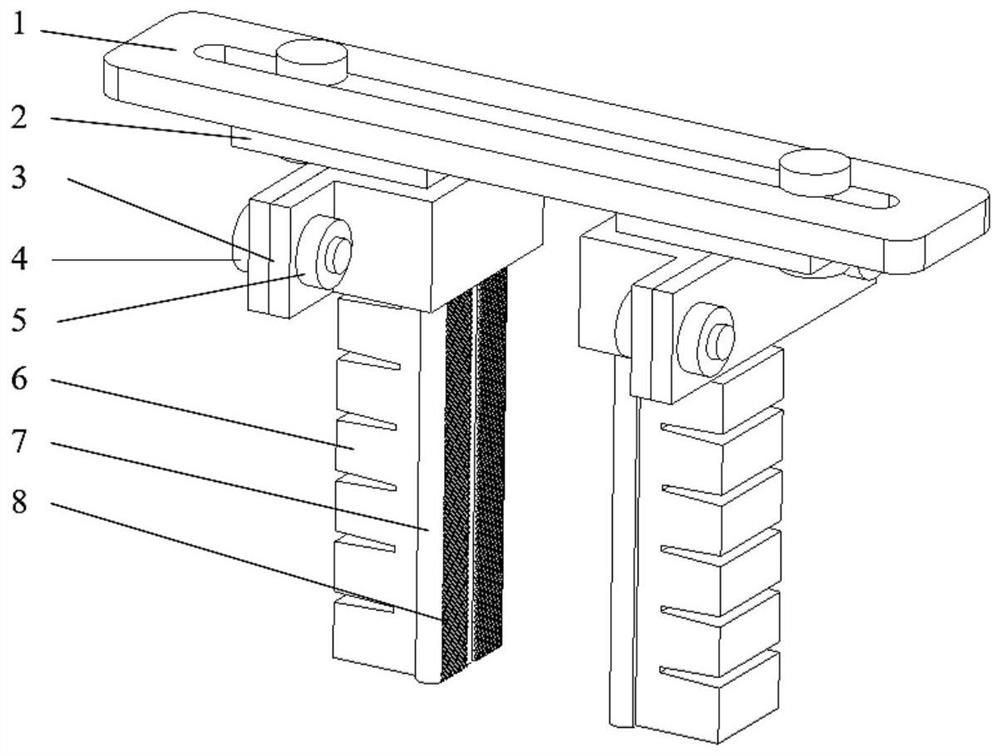

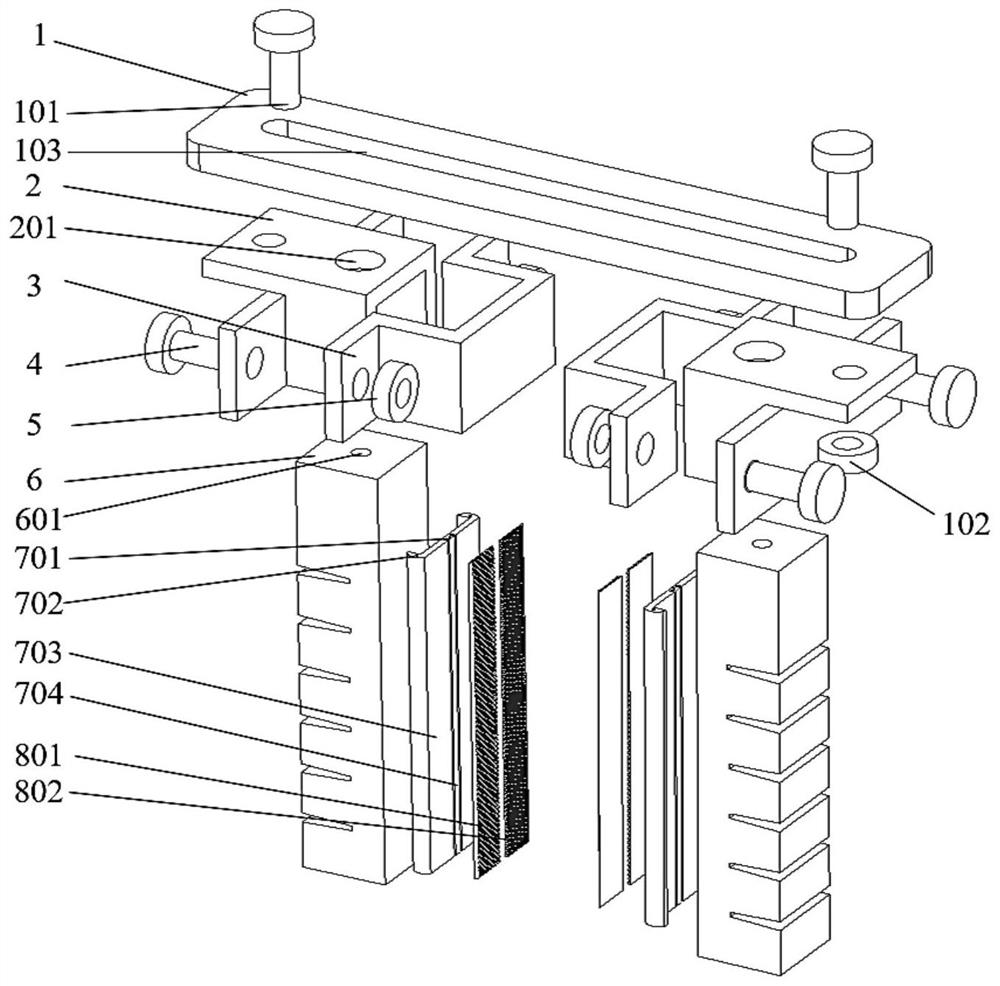

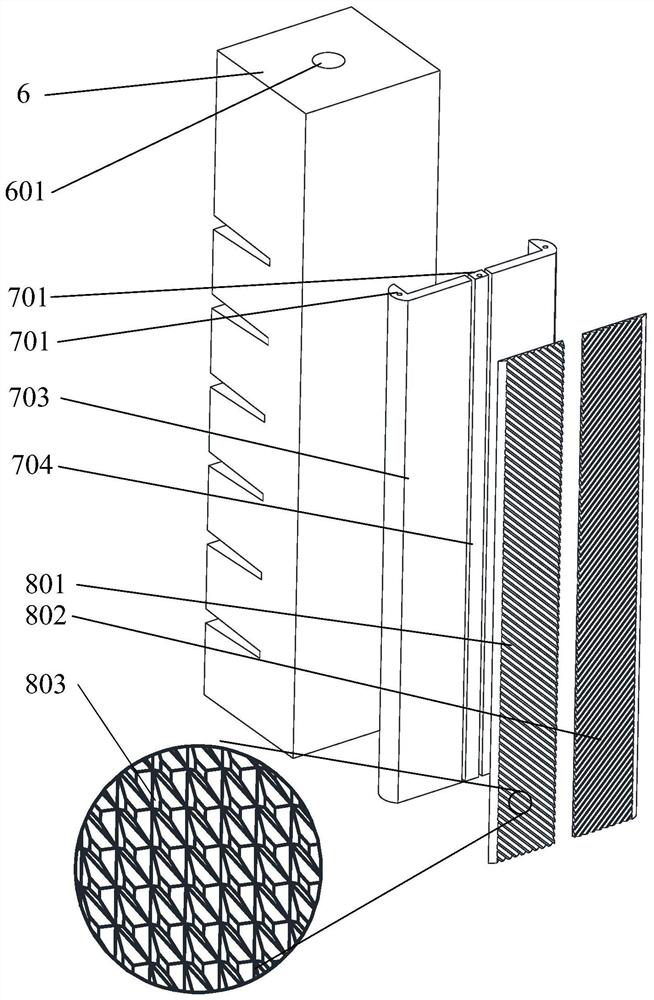

[0017] Such as figure 1 with figure 2 As shown, this embodiment includes: a pair of pneumatic fingers 6 relatively slidably arranged on the gripper fixing frame 1, wherein: the opposite sides of the pneumatic fingers 6 are provided with a detachment air chamber 7 and a dry adhesive layer 8 in sequence.

[0018] The sliding setting is realized by connecting the handle fixing frame with the adjustment groove 103 on the handle fixing frame 1 and the pneumatic fingers respectively.

[0019] Such as figure 1 As shown, the position of the handle fixing frame 2 can be adjusted on the handle fixing frame 1 and fixed on the handle fixing frame 1 through the adjustment groove 103 using bolts 101 and nuts 102 .

[0020] The gripper fixing frame 2 is used to install and fix the top of the pneumatic finger 6, use the compression plate 3 to compress the pneumatic finger 6 to fix it in the gripper fixing frame 2, use the bolt 4 and the nut 5 to connect the gripper and fix it The frame 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com