Method for promoting discharging stabilization of reinforced polypropylene (HRPP) double-wall corrugated pipe for buried drainage and pollution discharge

A technology of double-wall corrugated pipe and drainage pipe, which is applied in the field of pipe material production, can solve the problems that the feeding device does not have the end of the drainage pipe, the surface of the pipe and the feeding drum is damaged, and the end of the drainage pipe is uneven, etc. Achieve the effects of improving oil supply efficiency, increasing service life, and improving sliding smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Example 1 introduces a reinforced polypropylene (HRPP) double-wall corrugated pipe used for buried drainage and sewage to promote the stability of blanking. By setting rubber raised strips 10 on the surface of the blanking cylinder 6, both the blanking cylinder 6 and the drainage can be improved. The static friction force between the pipes can also utilize the elasticity of the rubber raised strip 10 to reduce the impact between the drain pipe and the blanking drum 6, so as to avoid damage to the drain pipe and the blanking drum 6 due to collision, as follows:

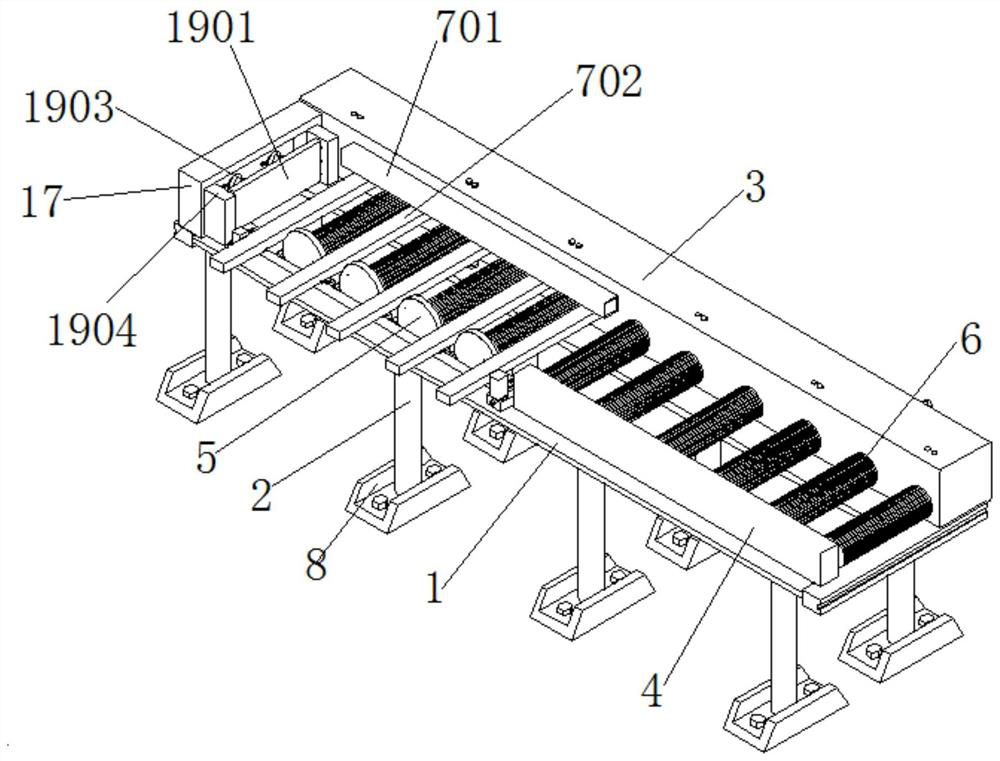

[0038] A reinforced polypropylene (HRPP) double-wall corrugated pipe for buried drainage and sewage to promote the stability of blanking, please refer to figure 1 , the blanking device includes a support frame 1, a support leg 2, a driving device housing 3, a driven device housing 4, a blanking drum support seat 5, a blanking drum 6, and a material rack 7;

[0039] The bottom end of the support frame 1 is fixedly...

Embodiment 2

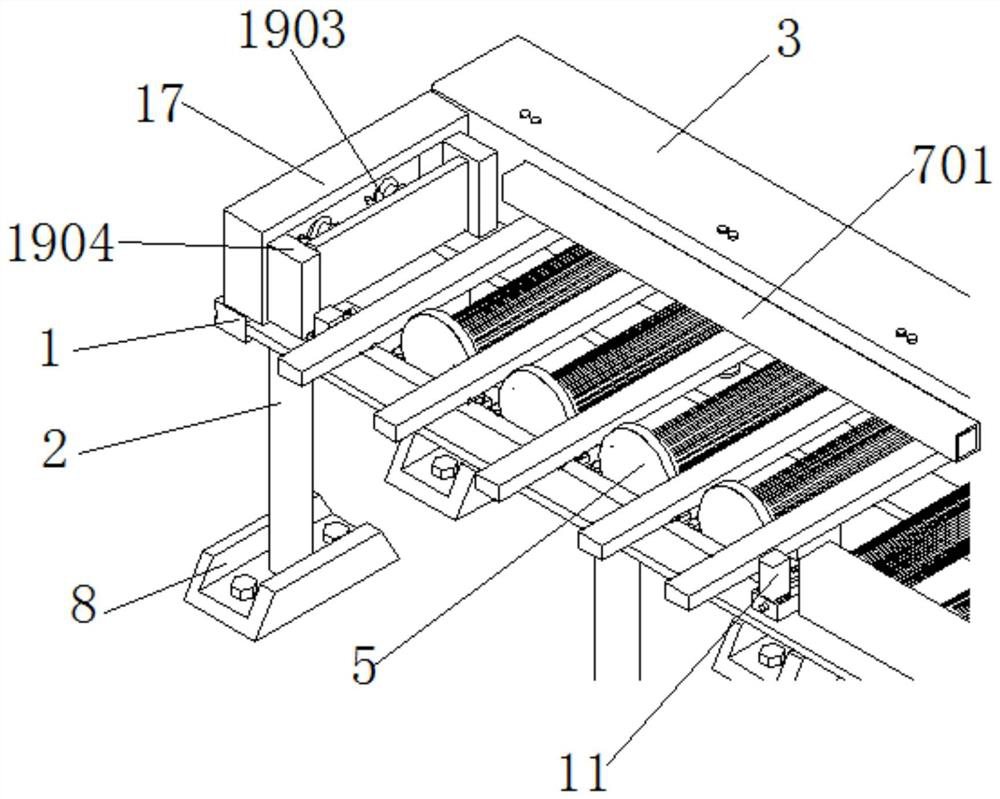

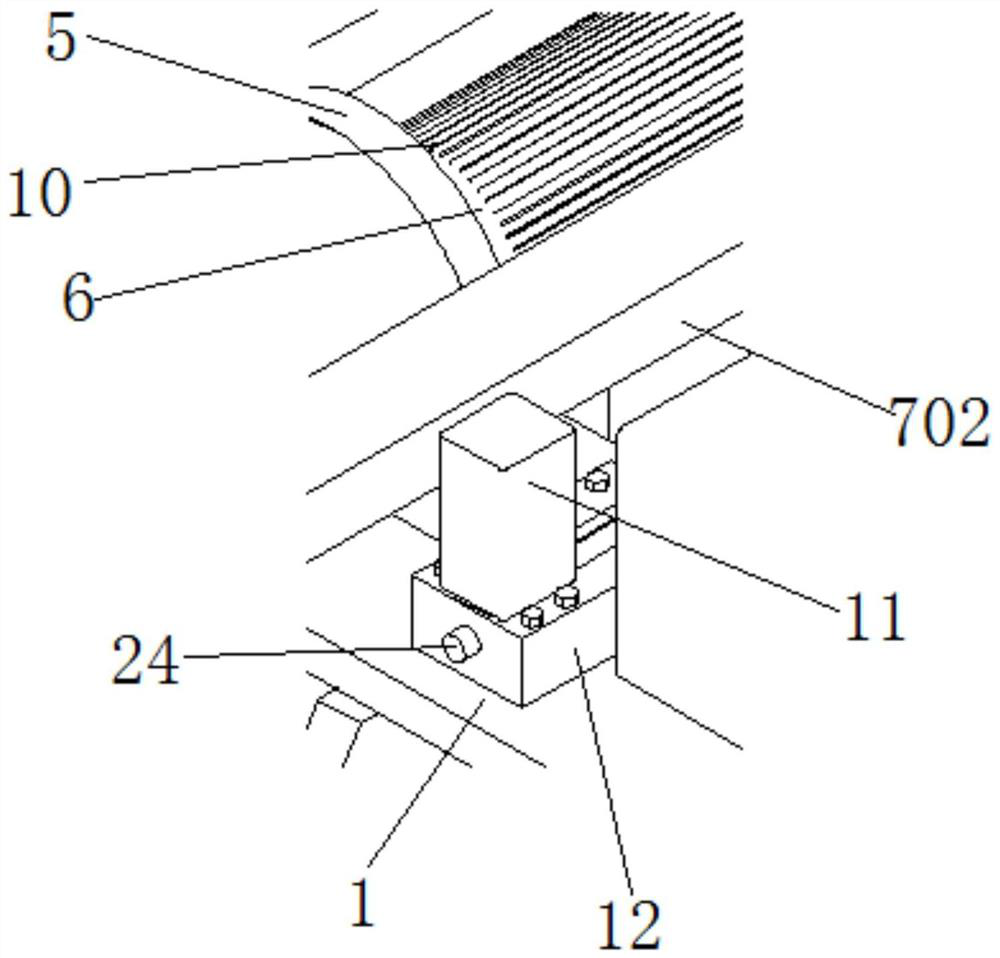

[0041] Embodiment 2 is an improvement on the basis of Embodiment 1. The main improvement is that the sliding seat 12 is added, and the distance between the fulcrum and the bottom end of the cylinder 16 can be changed by sliding the support pile 11 left and right. The cylinder 16 can be installed vertically on the On the support frame 1, the damage to the cylinder 16 caused by the bombing operation is reduced; the oil storage bin 20 is arranged at the bottom of the slide seat 12, and the oil supply roller 21 can provide lubricating oil to the slide block 14 at all times, and improve the slide block 14 and the chute. 13 sliding smoothness; further by coating the liquid-absorbing sponge pad 25 on the periphery of the blanking drum 6, the oil supply efficiency of the blanking drum 6 can be improved. The specific improvements are as follows.

[0042] A reinforced polypropylene (HRPP) double-wall corrugated pipe for buried drainage and sewage to promote the stability of blanking, pl...

Embodiment 3

[0046] Embodiment 3 is to increase the end alignment plate 17 on the basis of Embodiment 2, which can ensure the alignment of the end of the drain pipe; adding a buffer mechanism 19 can reduce the impact force generated when the drain pipe is aligned, and avoid the end of the drain pipe and the buffer plate 1901. Damaged during the collision; adding guide reinforcement blocks 1904 and balls 1905 can strengthen the guiding effect on the buffer plate 1901, even when the impact force generated by several drain pipes on the buffer plate 1901 does not pass through the center of the buffer plate 1901 When the line is aligned, the guide reinforcement block 1904 can play an auxiliary effect on the buffer plate 1901, reduce the inclination of the buffer plate 1901, thereby reducing the wear degree of the guide movable rod 1902, and improving the service life of the guide movable rod 1902. The specific improvements are as follows:

[0047] A reinforced polypropylene (HRPP) double-wall c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com