PRM concrete reinforcing agent

A concrete reinforcing agent and fully mixed technology, which is applied in the field of comprehensive utilization of red mud, gypsum, and fly ash, can solve the problems of high concrete production cost, high cost, and large amount of cement, and solve the problem of environmental protection and solid waste treatment. Low, high-intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The PRM concrete reinforcing agent described in this embodiment is prepared from 100 kilograms of red mud, 300 kilograms of red gypsum, 100 kilograms of fly ash and 500 kilograms of ore powder; its preparation method is: first mix red mud, gypsum, fly ash Filter out particles with a diameter of 0.5 cm or more, and mix them well after drying.

Embodiment 2

[0016] The PRM concrete reinforcing agent described in this embodiment is prepared from 300 kilograms of red mud, 100 kilograms of white gypsum, 500 kilograms of fly ash and 100 kilograms of ore powder; its preparation method is: first mix red mud, gypsum, fly ash Filter out particles with a diameter of 0.5 cm or more, and mix them well after drying.

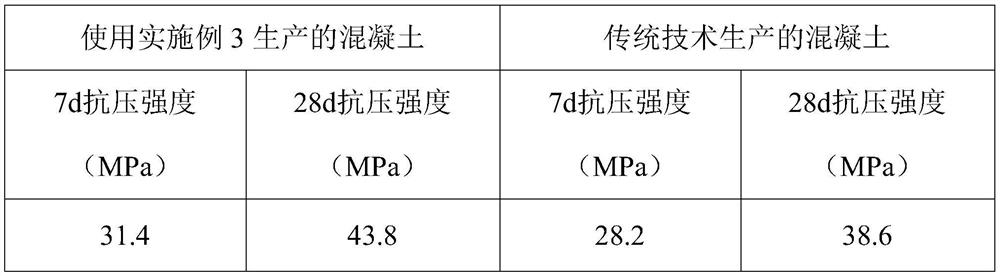

Embodiment 3

[0018] The PRM concrete reinforcing agent described in this embodiment is prepared from 200 kilograms of red mud, 200 kilograms of desulfurized gypsum, 400 kilograms of fly ash and 400 kilograms of mineral powder; its preparation method is: first mix red mud, gypsum, fly ash Filter out particles with a diameter of 0.5 cm or more, and mix them well after drying.

[0019] In the production of concrete mixing, the chemical reaction product and strength enhancement mechanism after adding the PRM concrete reinforcing agent of the present invention are as follows:

[0020] 1. Red mud (containing NaOH) + gypsum (containing 2H2O CaSO4) → ettringite (calcium-aluminum → calcium-aluminum gypsum)

[0021] In the process of concrete gelation reaction, red mud and gypsum will promote the formation of ettringite (calcium-aluminum gypsum), fill the pores and make the slurry dense, which is conducive to the development of strength.

[0022] 2. Red mud (containing NaOH) + fly ash (amorphous Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com