Recycled polyester yarn and manufacturing process thereof

A technology of regenerated polyester and manufacturing process, applied in the field of regenerated polyester yarn, can solve the problems of polyester yarn corrosion, low polyester yarn strength, affecting fabric quality, etc., to achieve increased strength, low manufacturing cost, improved adaptability and The effect of the scope of adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

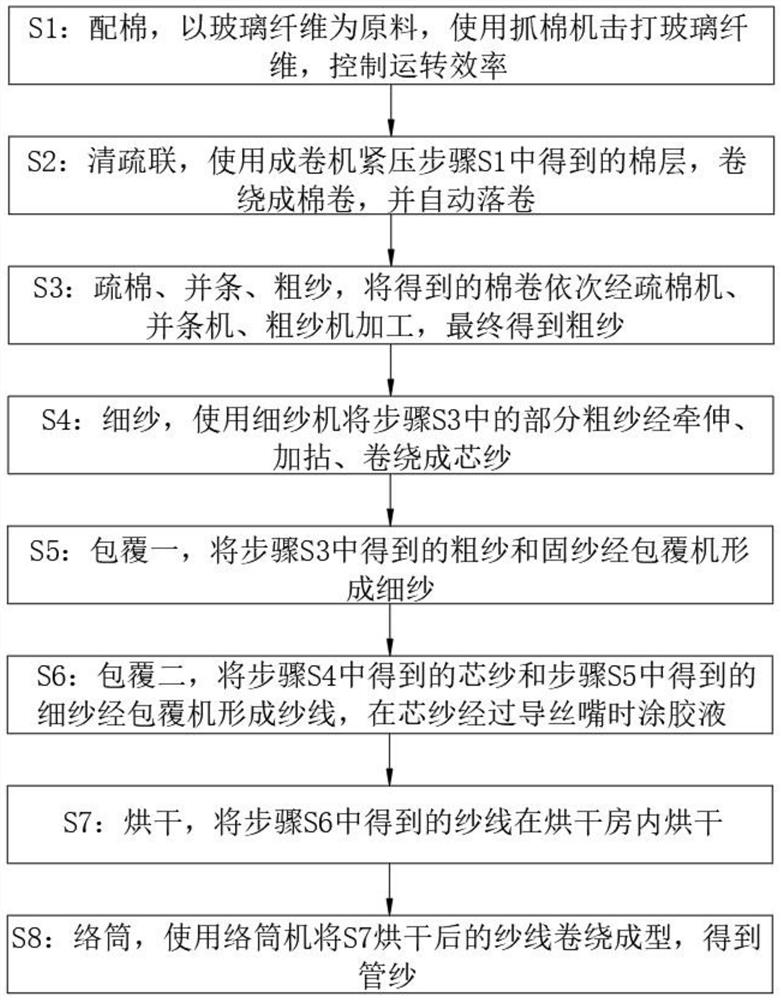

[0049] A kind of manufacturing process of regenerated polyester yarn, comprises the following steps successively:

[0050] S1: Cotton blending, based on the principle of full mixing, use the cotton plucking machine to hit the glass fiber. The cotton catching machine can use a reciprocating cotton catching machine to improve the loosening effect of the cotton layer, so that the cotton layer is fully mixed. The total pressure in the cotton pipe is - 80MPa, the speed of the catcher is 1350r / min, and the cotton layer is obtained;

[0051] S2: Cleaning and thinning, use the lapping machine to compress the cotton layer obtained in step S1, wind it into a lap, and automatically doff the lap. The distance between the lap roller and the lap puller is 6mm, and the lap length 40m, lap diameter 450mm;

[0052] S3: Sweeping, drawing, and roving, the obtained cotton laps are sequentially processed through a doffing machine, a drawing frame, and a roving frame. The dotting machine will open...

Embodiment 2

[0059] A kind of manufacturing process of regenerated polyester yarn, comprises the following steps successively:

[0060] S1: Cotton blending, based on the principle of full mixing, use the cotton plucking machine to hit the glass fiber. The cotton catching machine can use a reciprocating cotton catching machine to improve the loosening effect of the cotton layer, so that the cotton layer is fully mixed. The total pressure in the cotton pipe is - 80MPa, the speed of the catcher is 1350r / min, and the cotton layer is obtained;

[0061] S2: Cleaning and thinning, use the lapping machine to compress the cotton layer obtained in step S1, wind it into a lap, and automatically doff the lap. The distance between the lap roller and the lap puller is 6mm, and the lap length 40m, lap diameter 450mm;

[0062] S3: Sweeping, drawing, and roving, the obtained cotton laps are sequentially processed through a doffing machine, a drawing frame, and a roving frame. The dotting machine will open...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com