Compound control method for waste incineration

A compound control and waste incineration technology, applied in the direction of combustion method, controlled combustion, self-adaptive control, etc., can solve the problems of incomplete decomposition of harmful substances, insecure economy and safety, and insufficient waste incineration, etc., to increase the dead zone Design, improve system stability, and improve the effect of applicability

Pending Publication Date: 2020-10-09

JIANGYIN JUNDA ELECTRIC AUTOMATION

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Stable combustion is the control goal of waste incineration, and the control method is a means to ensure its stability. Ineffective control methods will lead to insufficient waste combustion, incomplete decomposition of harmful substances, and no guarantee for its economy and safety.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0040] Such as Figure 7 , the actual step response shows that the closed-loop intelligent controller meets the requirements of the dynamic characteristics of the system and is also helpful to the stability of the system; the artificial empirical open-loop control method significantly improves the system response speed in the case of large external disturbances The control performance of the system is improved.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

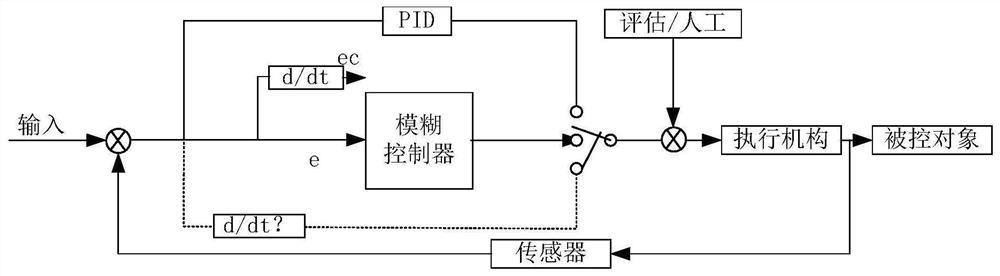

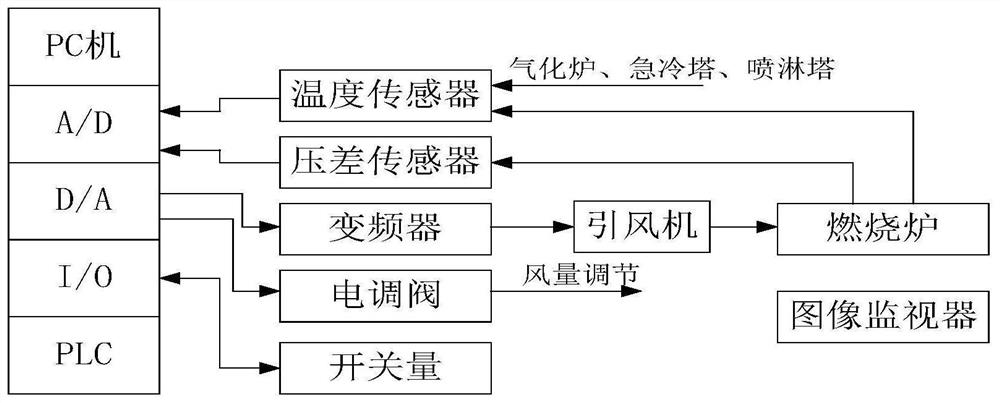

The invention relates to a compound control method for waste incineration. The control strategy of fuzzy control, traditional PID and open-loop control combined switch-shifting-type human thinking mode simulation is adopted, the error change rate adopts different control modes under a certain condition, meanwhile the load disturbance variable or the personnel empirical value is fed in through an open-loop mode, and the control precision is improved on the basis of ensuring stability. Fuzzy control adopts a two-dimensional control mode, the control rule uses the triangular membership function,and system dynamic performance is improved; incremental traditional PID adopts a canonical algorithm, and the system stability is improved; and disturbance control adopts an expert assessment weighting method to obtain the output quantity, direct loop opening acts on a control object, and the system response speed is increased. The intelligent-type control strategy integrating the various controlmodes and setting the criterion according to personnel experience for mode switching is adopted, and the good dynamic performance quality of control over a waste-incineration-type multi-parameter-object, nolinear and strongly-coupled system is achieved.

Description

technical field [0001] The invention relates to a compound control method for waste incineration. It belongs to the technical field of automatic control. Background technique [0002] Waste incineration is a waste treatment method with broad prospects. It is to fully burn waste through excess air under high temperature conditions, so that harmful substances can be oxidized and decomposed under high temperature, making waste harmless, reduced, and environmentally friendly. and regeneration. However, the composition of garbage is very complex, and its chemical structure and physical properties are not the same. In order to fully burn the garbage while reducing toxicity, the incineration process becomes very complicated. [0003] In order to ensure the operating efficiency of the waste incineration plant, the stability of the system is an important part, and the stability of the system requires a stable and efficient control method to ensure it. Waste incineration is a compl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F23G5/50G05B11/42G05B13/04F23N1/02

CPCF23G5/50G05B11/42G05B13/04F23N1/022

Inventor 王澜陈海国李峰钱伟赵小宝胡晓张翼蛟陈鹏

Owner JIANGYIN JUNDA ELECTRIC AUTOMATION

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com