Gas supply method and device for detecting content of hydrogen in solid metal

A gas supply device and a technology for hydrogen content, which are applied in the field of gas supply methods and devices for detecting hydrogen content in solid metals, can solve the problems of single gas supply method, low degree of automation, affecting detection results, etc., and achieve faster analysis time and automation. The effect of high degree and improved detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

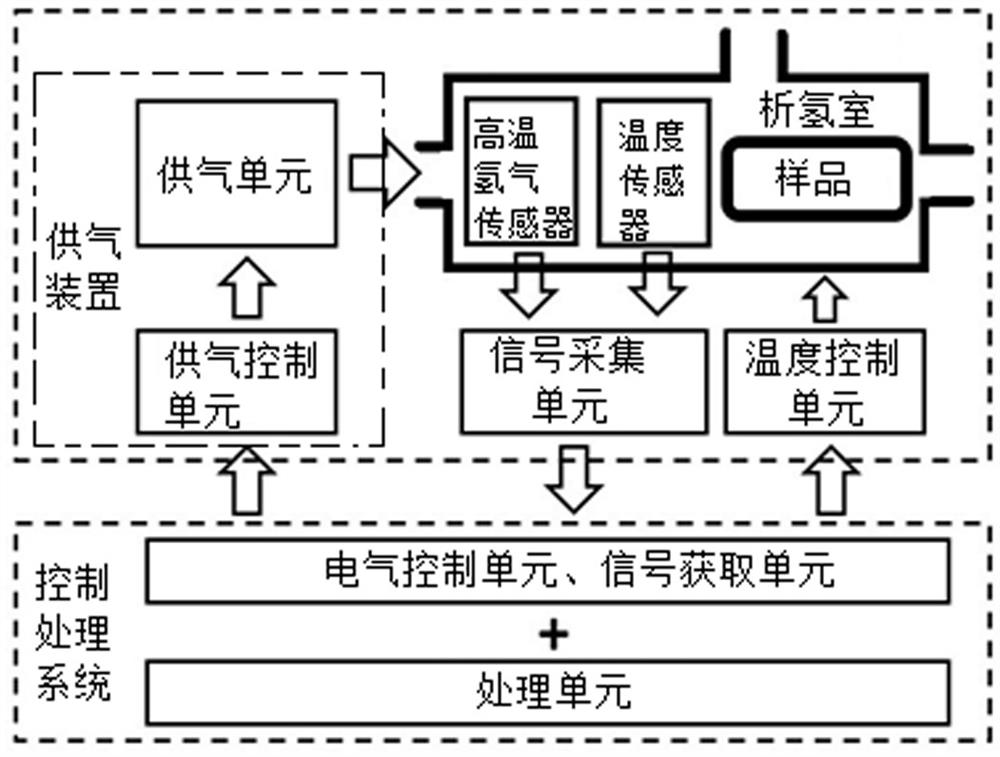

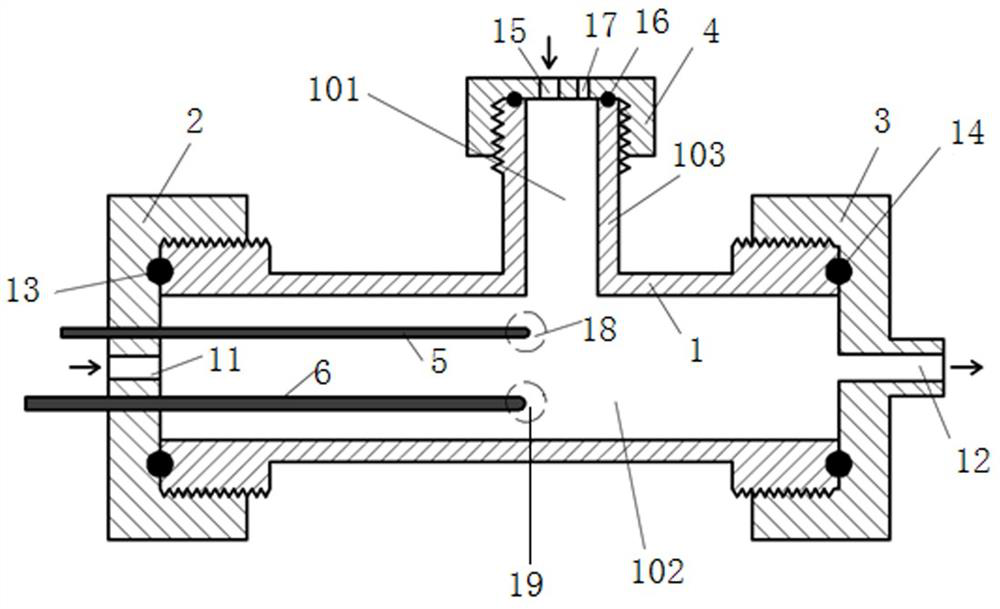

[0047] Embodiment 1: According to this embodiment of the present invention, a device for detecting hydrogen content in solid metal is provided, figure 1 It is a structural block diagram of the detection device of the present invention, such as figure 1 As shown, the device mainly includes: gas supply control unit, gas supply unit, hydrogen evolution chamber, signal acquisition unit, temperature control unit and control processing system.

[0048] During the test, the solid metal sample is placed in the hydrogen evolution chamber, and the gas supply unit is connected to the hydrogen evolution chamber to provide the hydrogen evolution chamber with a carrier gas for purging the solid metal sample before heating and serving as a hydrogen carrier during the hydrogen evolution process. The air supply control unit and the air supply unit together form an air supply device, and the air supply control unit is connected with the air supply unit to realize the control of the air supply u...

Embodiment 2

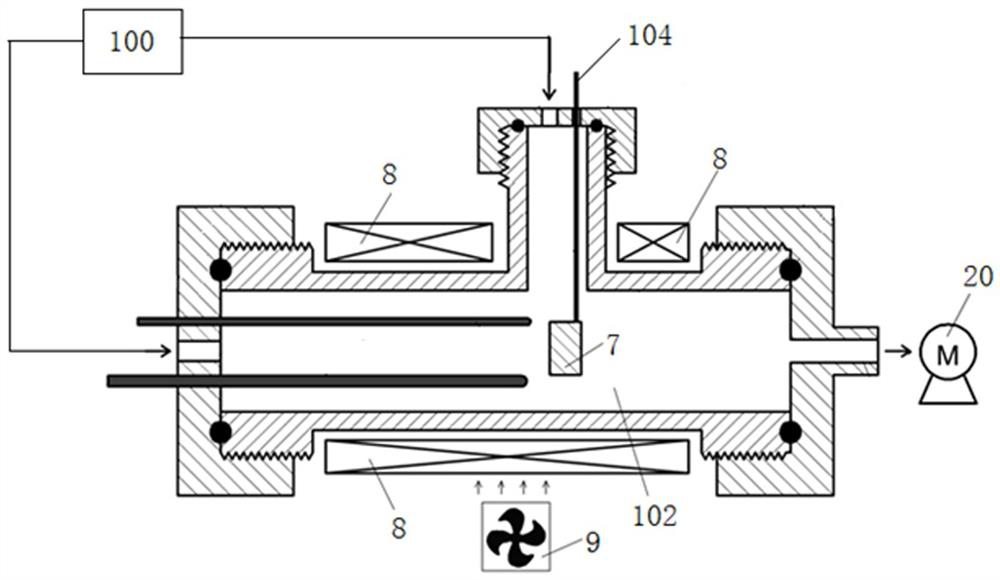

[0062] Embodiment 2: According to this embodiment of the present invention, a detection method using the hydrogen content detection device in the solid metal described in the foregoing embodiment 1 is provided. When the hydrogen content is detected, the solid metal sample 7 is first placed in the hydrogen evolution chamber In the sample pre-release area 101, the temperature and hydrogen concentration in the hydrogen evolution chamber are detected by the temperature sensor 5 and the high-temperature hydrogen sensor 6. The carrier gas is supplied to the sample prevention area 101 and the heating area 102 of the hydrogen evolution chamber through the gas supply unit 100 . The carrier gas is nitrogen or inert gas that does not react with hydrogen and solid metal. Before measuring hydrogen, the air in the hydrogen evolution chamber needs to be exhausted. Before the carrier gas is introduced, the hydrogen evolution chamber can be evacuated by the vacuum pump 20 outside the hydrogen ...

Embodiment 3

[0068] Embodiment 3: According to this embodiment of the present invention, there is provided a gas supply device for the detection of hydrogen content in solid metals in the foregoing embodiments 1 and 2. The gas supply device provided in this embodiment can be solid The carrier gas is provided when the hydrogen content of the metal sample is detected, and the hydrogen-containing calibration gas can also be provided for the calibration of the detection device. The calibration requirements of different hydrogen concentrations can realize the calibration of high-temperature hydrogen sensors, avoid the influence of the sensor's own factors on the detection accuracy of metal hydrogen content, and improve the detection accuracy of data; by selecting large flow gas flow controllers and small flow gas flow control The device can meet the requirements of different gas flows into the hydrogen evolution chamber, improve the accuracy of gas flow control, and further improve the accuracy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com