In-service drill rod detection device and method

A detection device and drill pipe technology, which is applied in the direction of measuring device, printing device, spraying device, etc., can solve the problems of time-consuming, labor-intensive, low precision, cumbersome manual operation steps, etc., to improve detection accuracy, improve work efficiency, and improve walking The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below with reference to the drawings and embodiments. Apparently, the described embodiments are part of the embodiments of the present invention, but not all of them.

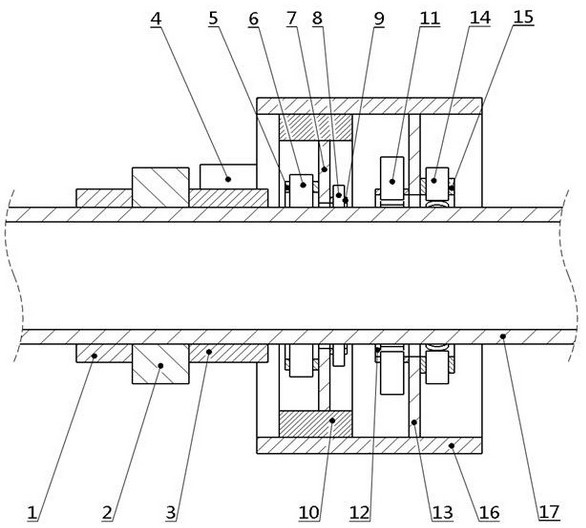

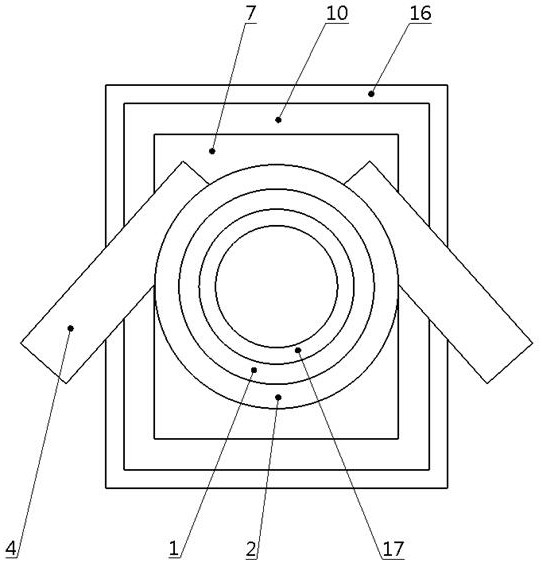

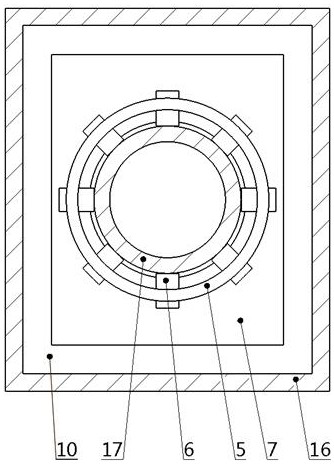

[0040] Such as Figure 1-6 As shown, an in-service drill pipe detection device includes: a cleaning and purging module, a magnetic flux leakage detection module, an outer diameter measurement module and a marking module, etc., wherein the cleaning and purging module consists of a wire brush 1, a compressed air blowing nozzle 2, The crawler actuator 3 and the crawler motor 4 are composed. The crawler motor 4 is installed and fixed on the side of the frame 16. One end of the crawler actuator 3 is fixed on the end of the frame 16, and the other end is fixed with a compressed air blowing nozzle 2. A wire brush 1 is fixed at the front end of the air purging nozzle 2 . The wire brush 1 is wrapped around the surface of the drill pipe 17 to clean up the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com