Performance evaluation and prediction method and system for life cycle of water quality sensor

A water quality sensor and life cycle technology, which is applied in the direction of testing water, material inspection products, etc., can solve the problems of lack of accuracy and real-time, status data induction, insufficient utilization, etc., and achieve the effect of solving low prediction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

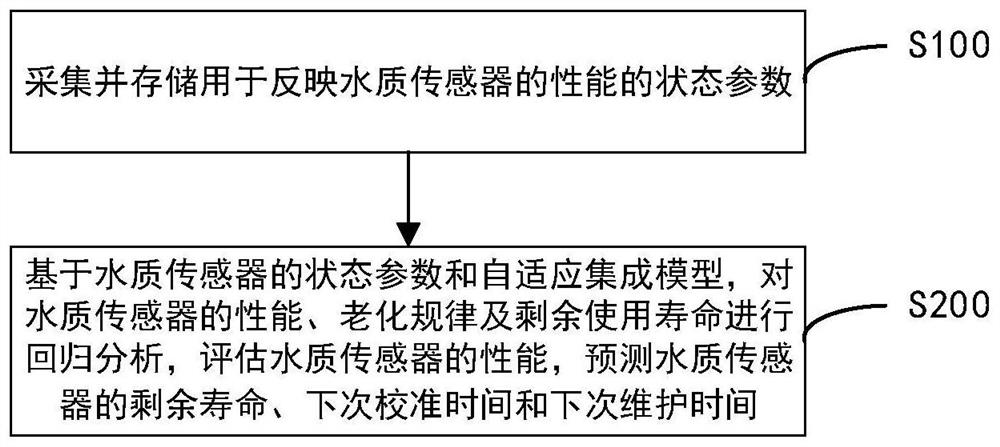

Method used

Image

Examples

Embodiment 1

[0093] Assuming that the water quality sensor is a pH sensor, collect the state parameter data of the pH sensor, estimate the development trend of historical data through mathematical modeling, obtain the curve of electrode life and time, that is, the life distribution, define the electrode wear limit, and predict the continuous operation of the sensor to reach the use time limit. It is assumed that the performance of the electrode can be described well enough by the model under the basic known properties, medium and environmental conditions.

[0094] (1) Using adaptive learning ideas to improve the model

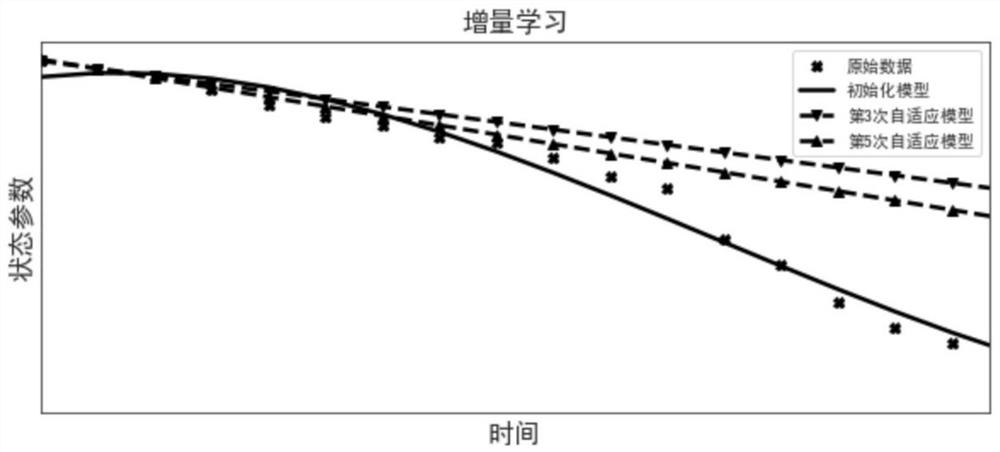

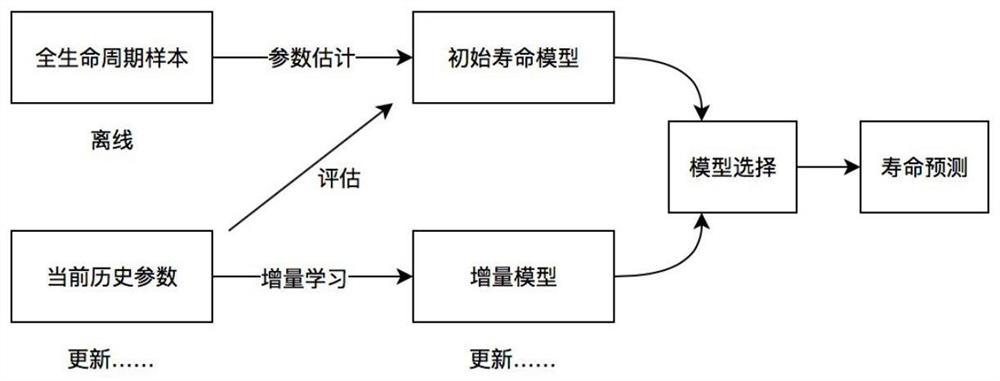

[0095] Such as Figure 2-3 As shown, based on the overall samples of the whole life cycle of each parameter, the parameters of the life distribution are estimated to obtain the initial life model, and the regression coefficients are optimized at the same time. The optimization methods include gradient descent and Newton's method. Evaluate the regression prediction effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com