Touch device and manufacturing method thereof

A technology of a touch control device and a manufacturing method, which are applied in the fields of instruments, electrical digital data processing, electrical components, etc., can solve the problems of limited reduction of the wiring area and the inability of the wirings to be too close together.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

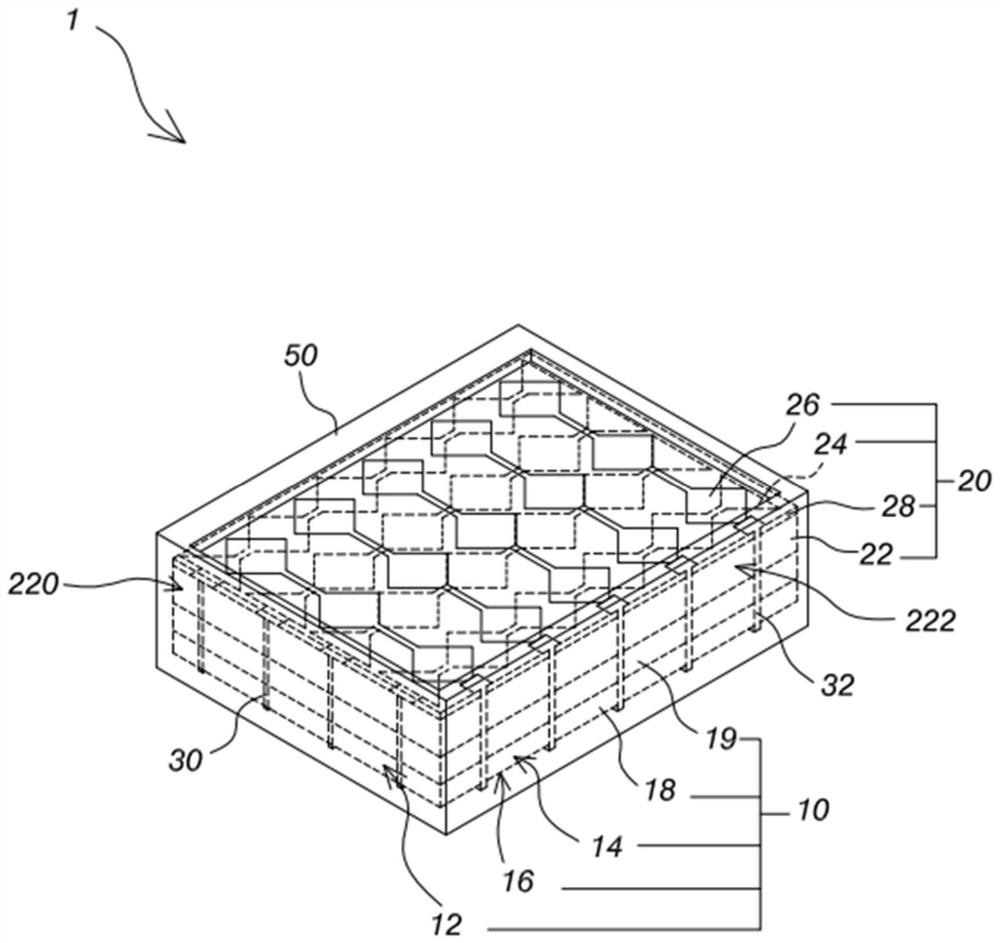

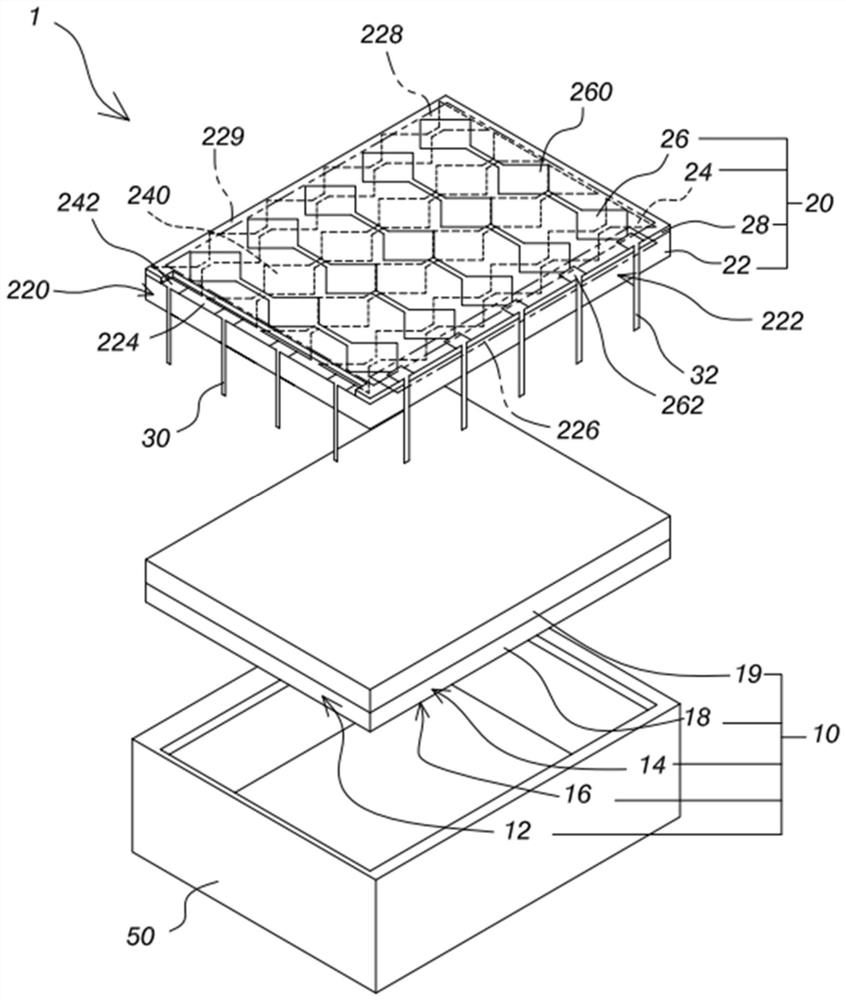

[0059] The present invention can provide a touch device, through a special structural design and hot-press bonding technology, so that the traces are completely attached to the side walls of the touch module and the display module, and there is no need to use the base material to protect the traces. Line, so that the bending radius of the line is not affected by the thickness and bendability of the substrate, which can greatly reduce the wiring area of the line and achieve the purpose of narrow frame.

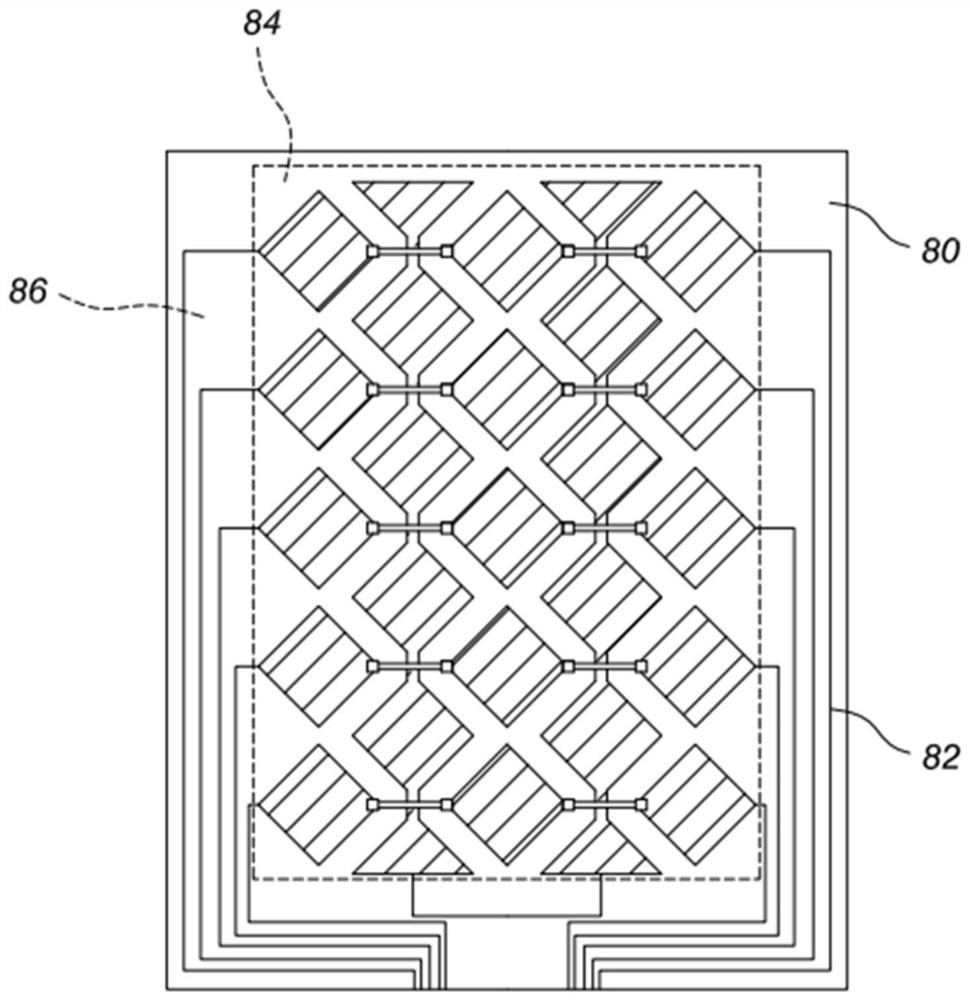

[0060] In order to better understand how the present invention achieves the above effects, the technology of the touch device and its manufacturing method is described in detail here, please refer to Figure 2 to Figure 5 Firstly, the structure of the touch device 1 is described. The touch device 1 includes a display module 10 , a touch module 20 , a plurality of first wires 30 and a plurality of second wires 32 . The touch module 20 is disposed on the display module 10 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com