Simulation method for obtaining hot spot temperatures of power transformer under different working conditions

A power transformer, hot spot temperature technology, applied in design optimization/simulation, instrument, image data processing, etc., can solve problems such as aging of insulating materials, accelerated chemical reactions, failures and accidents of transformers not reaching expected life, and facilitate calculation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Below in conjunction with accompanying drawing, the present invention is described in detail

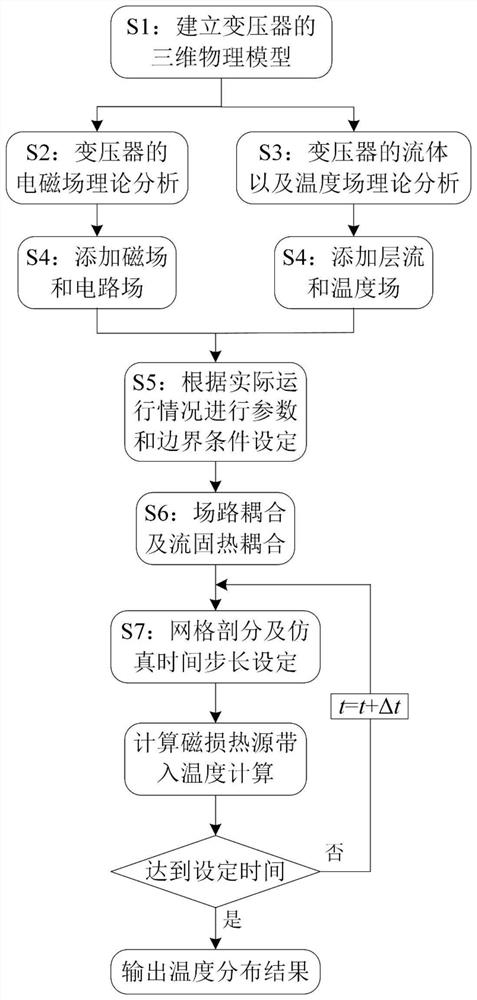

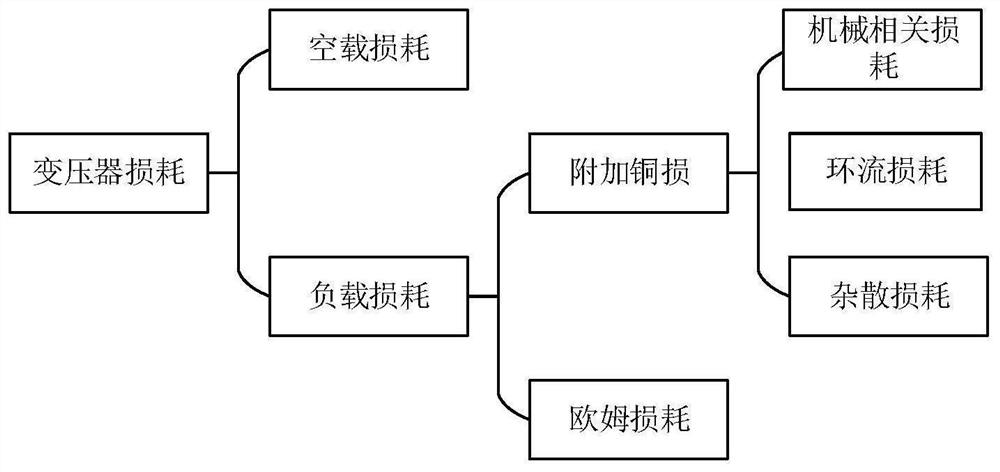

[0064] The invention is a simulation method for obtaining the temperature of hot spots under different working conditions of a power transformer. Based on the actual structure of the oil-immersed transformer, a three-dimensional simulation model of the temperature rise of the transformer is established by using the method of combining the finite element and the finite volume method. The influence of factors such as electromagnetic field and oil flow on temperature can realize the simulation of transformer hot spot temperature distribution. Specific steps are as follows:

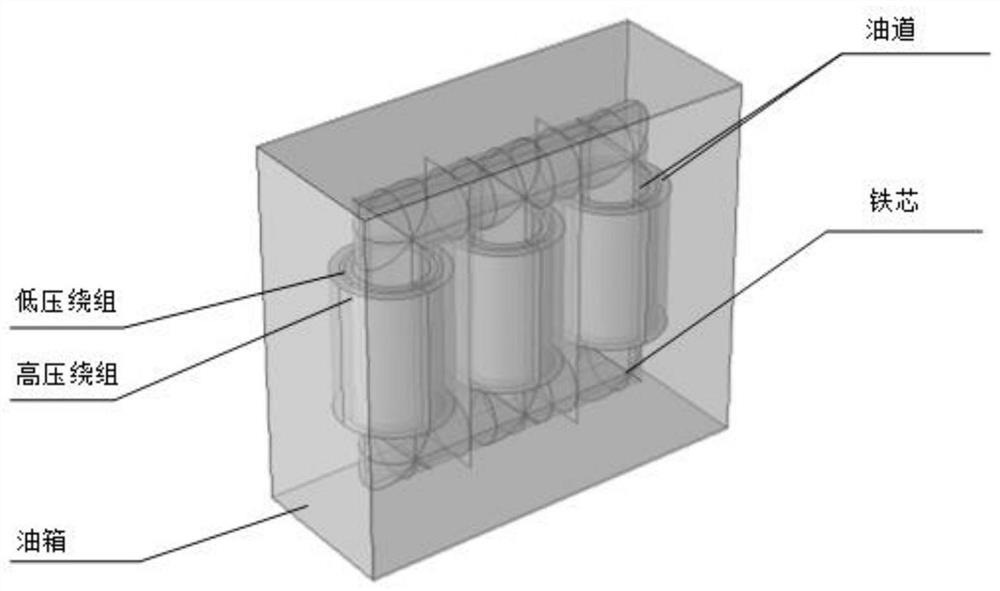

[0065] 1. Establish a three-dimensional physical model of the power transformer

[0066] In the finite element software, the three-dimensional model of the transformer temperature field is established, such as image 3 As shown, when performing coupling analysis, an important feature of the internal structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com