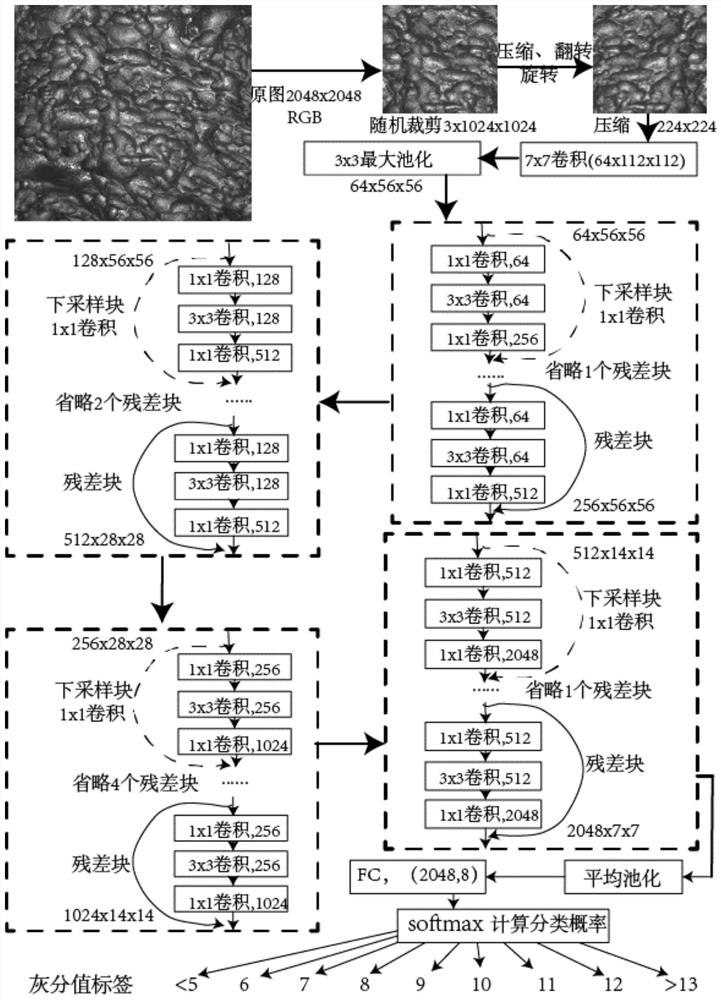

Coal slime flotation clean coal ash content prediction method based on deep learning

A coal slime flotation and deep learning technology, applied in flotation, solid separation, instruments, etc., can solve the problems of low precision and difficulty in online automatic monitoring of flotation clean coal ash in coal preparation plants, and achieve good adaptability and shorten Modeling time, the effect of accurate prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

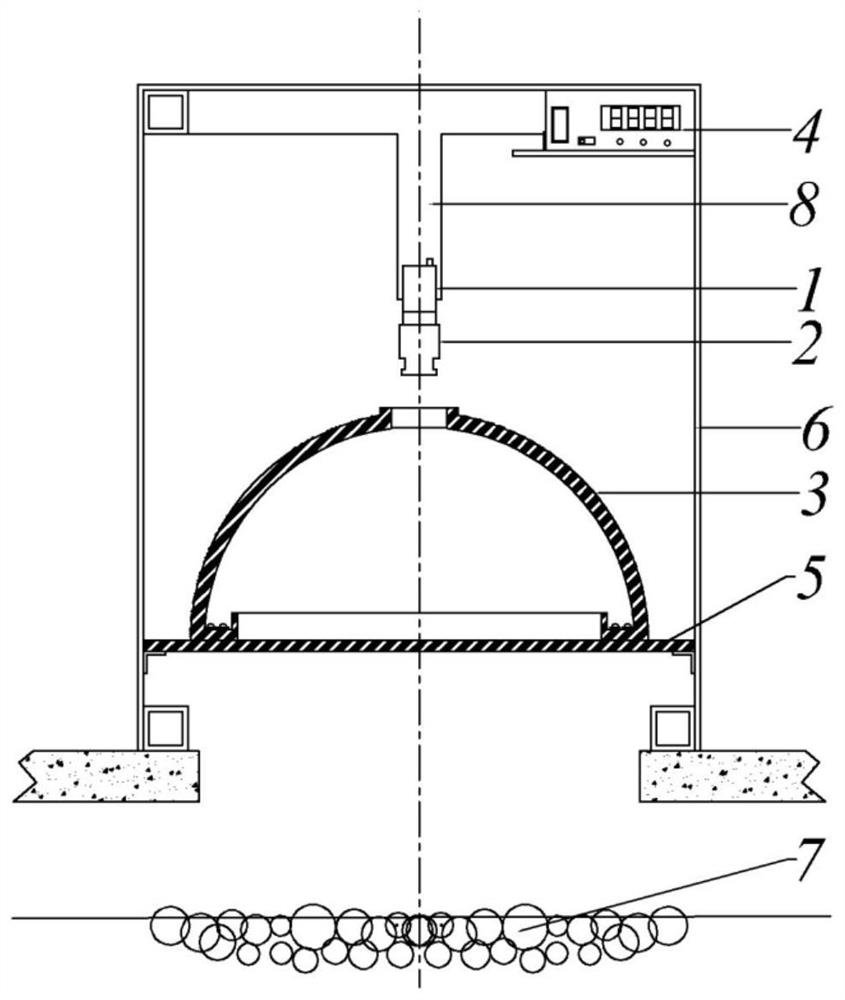

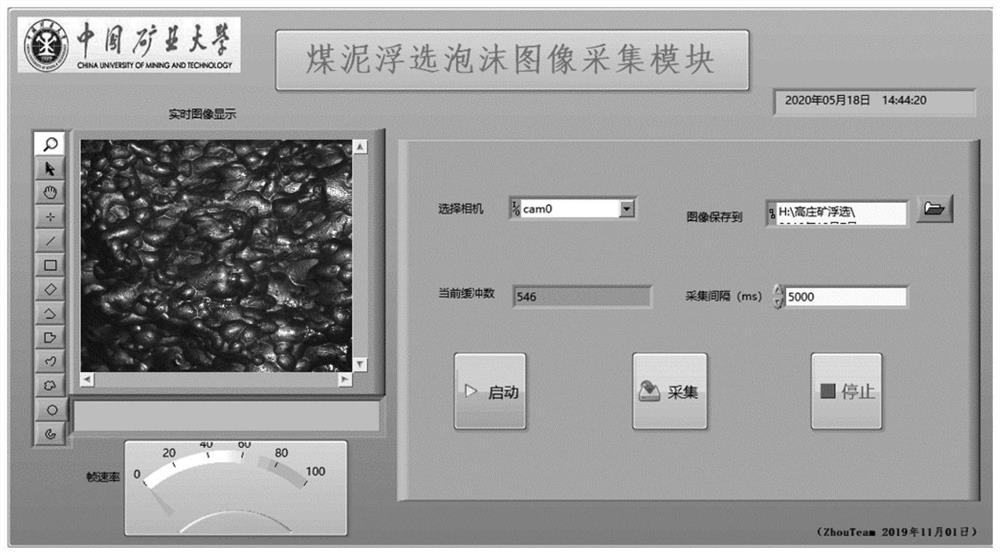

[0061] In order to enable those skilled in the art to better understand the present invention, the specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0062] (1) Equipment selection

[0063] The equipment mainly involved in the present invention includes: CCD industrial camera 1 (balser, ace a2040-20gc), fixed-focus lens 2 (computer, 30mm), light source 3 (LED diffuse reflection backlight), light-transmitting glass 5, light source controller 4 , Lens hood 6, camera bracket 8, gigabit network cable (CAT-6 and above), computer.

[0064] (2) On-site layout

[0065] Combined with the operating conditions of the flotation machine and the flotation column, it is found that the foam layer on the surface of the flotation cell 7 is mainly divided into three states. The foam in the middle part moves very slowly, which is not representative. It is too fast and the foam disturbance is relatively large with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com