Fixed-point reinforced cable capable of automatically inhibiting bending angle

A self-inhibiting and reinforcing technology, applied in the direction of bendable cables, insulated cables, and bendable conductors, can solve problems such as hardening, achieve the effects of improving strength and hardness, protecting aging damage, and suppressing the bending range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

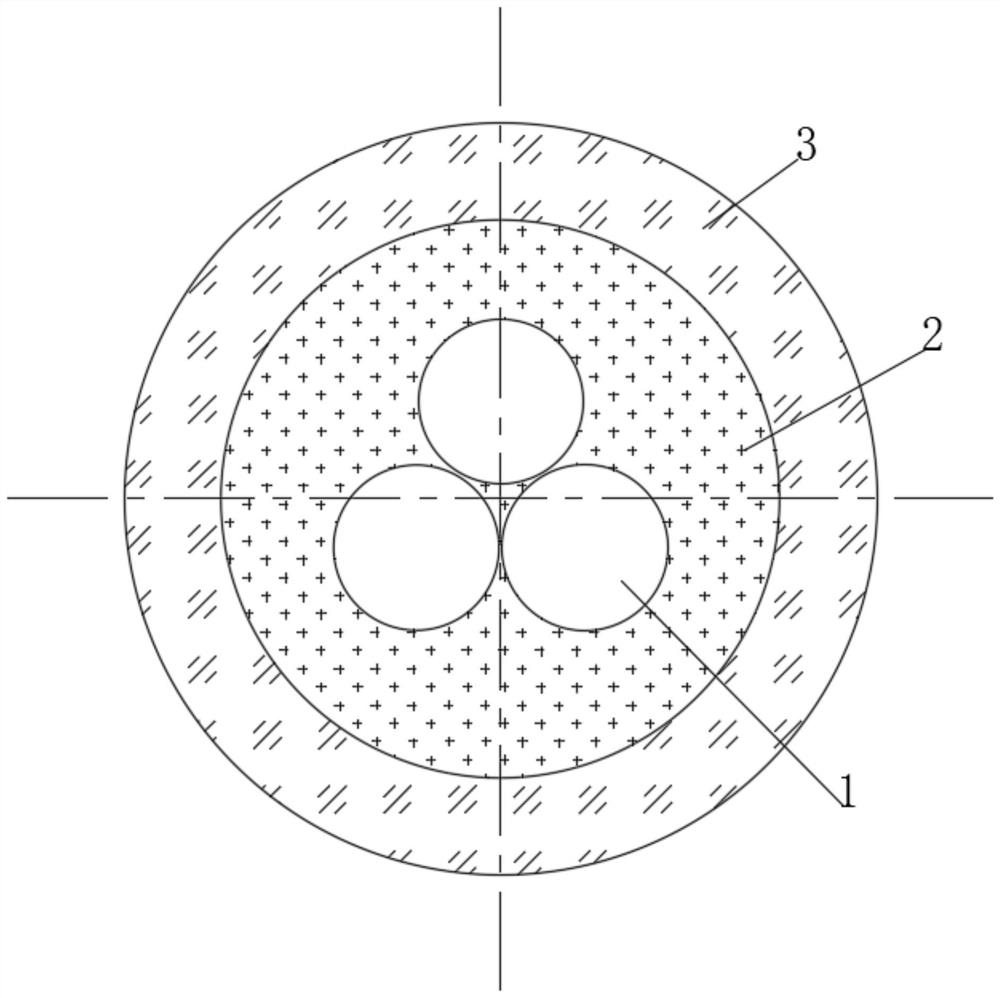

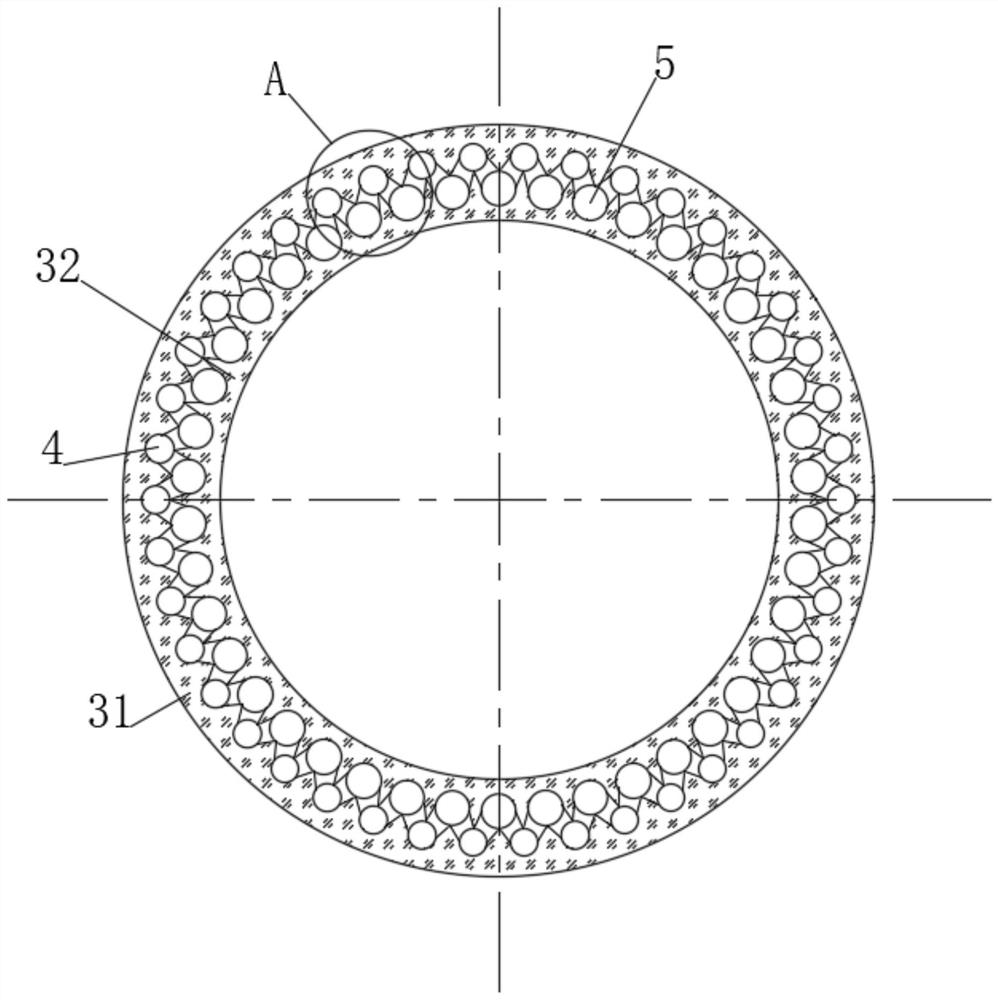

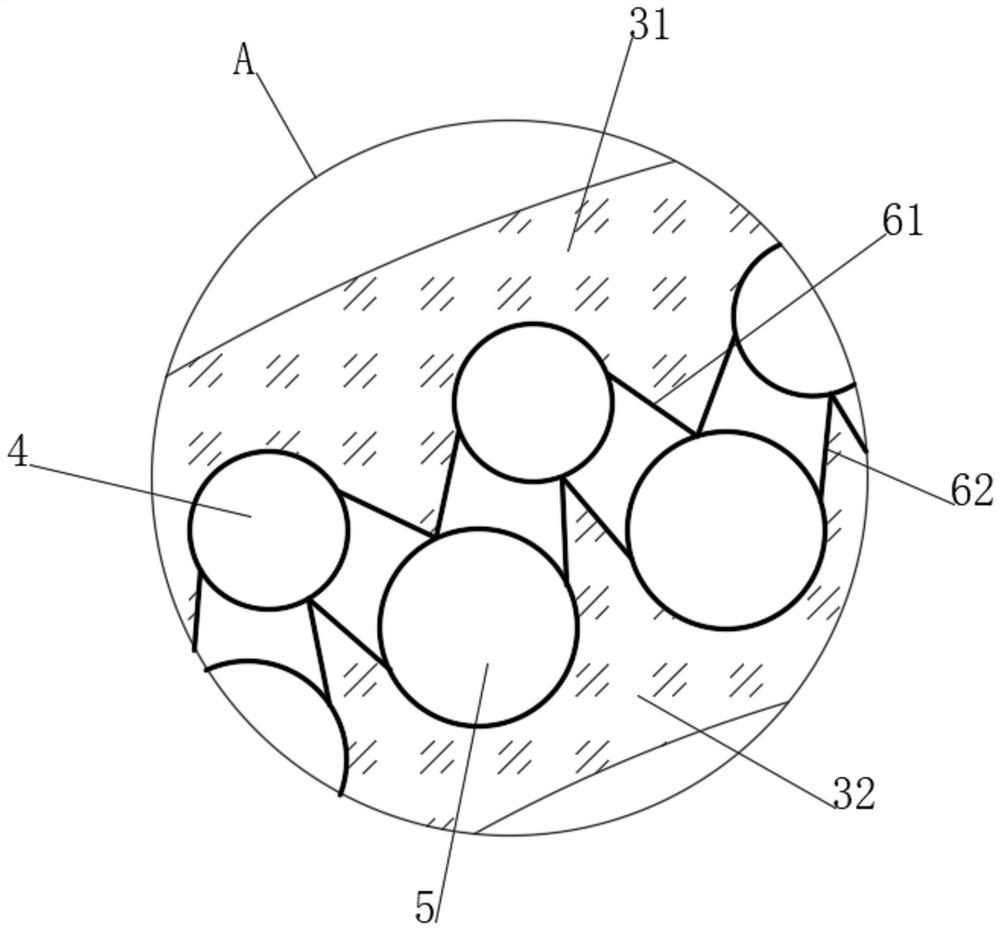

[0038] see Figure 1-2 , a fixed-point reinforcement type self-suppressing bending angle cable, comprising a plurality of wire cores 1, the outer end of the wire core 1 is wrapped with an insulating layer 2, the outer end of the insulating layer 2 is wrapped with an outer sheath layer 3, and the outer sheath layer 3. The interior is inlaid with a plurality of circularly distributed outer multi-ball-point restraint rods 4 and inner multi-ball-point restraint rods 5. The inner multi-ball-point restraint rods 5 are located inside the outer multi-ball-point restraint rods 4. 4 and the inner multi-ball point suppression rod 5 divide the outer sheath layer 3 into an outer anti-thrust layer 31 and an inner thrust layer 32, the outer anti-thrust layer 31 is located outside the outer multi-ball point suppression rod 4, and the inner thrust layer 32 is located at the inner multi-ball point suppression rod 4. Inner side of the ball point suppression rod 5, the outer anti-thrust layer 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com