Electrostatic dusting machine for glass production line

A glass production line and powder sprinkler technology, which is applied to the surface pretreatment, coating, and device for coating liquid on the surface, etc., can solve the problems of glass breakage, powder moisture, powder agglomeration, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

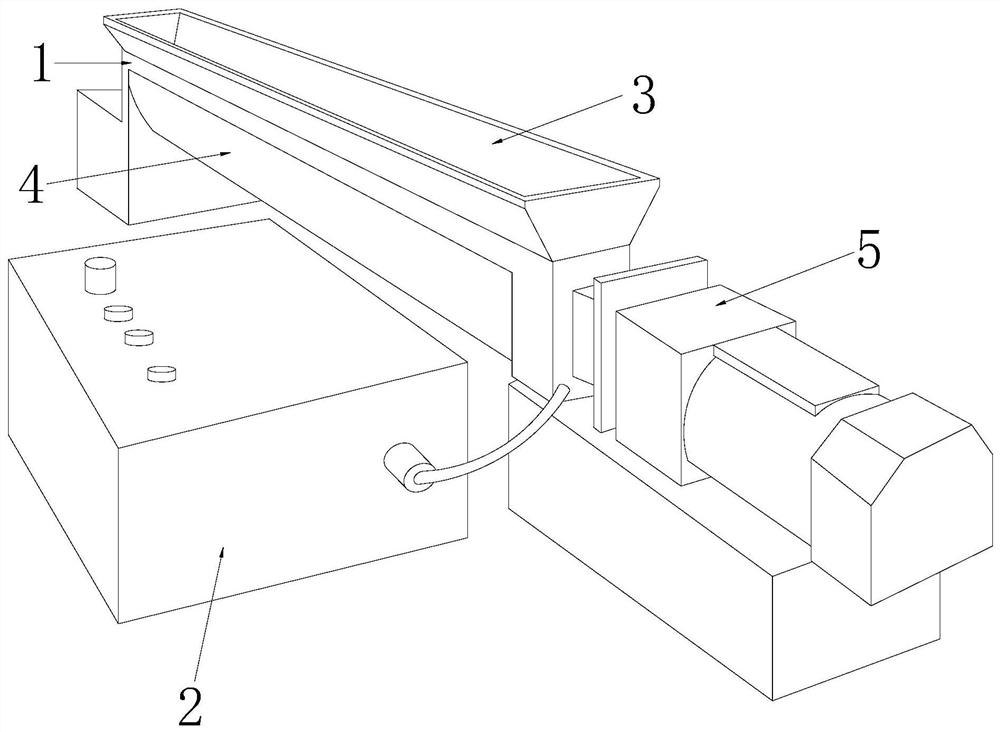

[0026] Such as Figure 1-Figure 5 As shown, the present invention provides a kind of technical scheme of electrostatic powder spreader for glass production line:

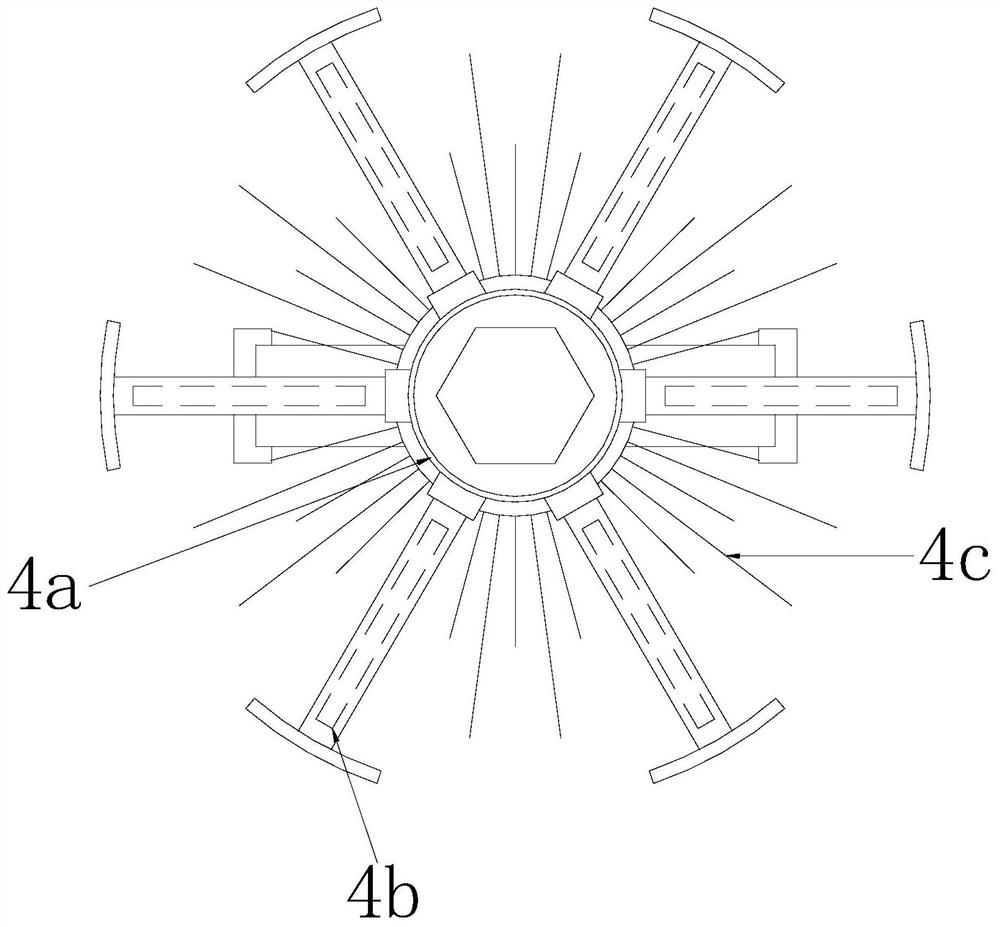

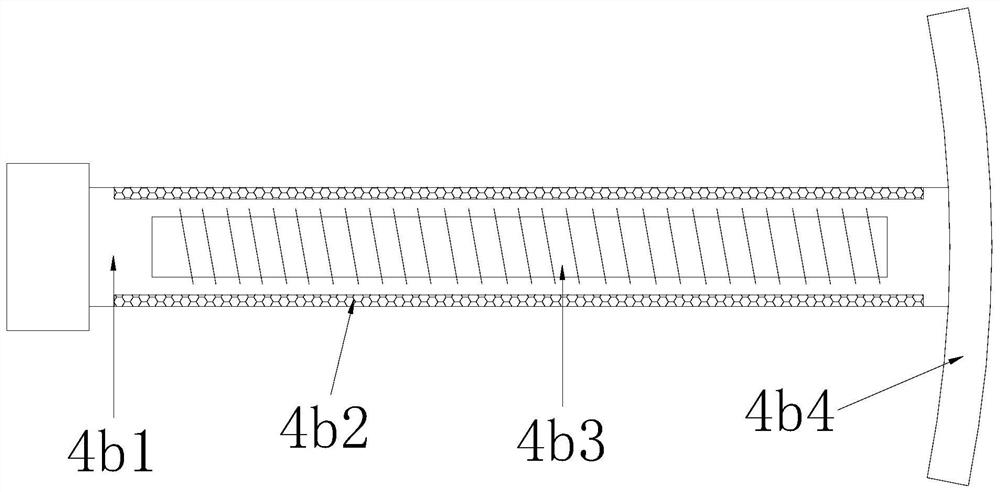

[0027] Such as Figure 1-Figure 2 Shown, a kind of electrostatic duster for glass production line, its structure comprises support 1, controller 2, silo 3, dispersing device 4, electric motor 5, and described silo 3 is located at the top of support 1 and is connected by electric welding. connected, the silo 3 is electrically connected to the controller 2, the dispersing device 4 is located at the bottom of the hopper 3 and is connected by electric welding and connected to the electric motor 5, the dispersing device 4 includes a rotating shaft 4a, Dispersion mechanism 4b and stirring mechanism 4c. There are six uniform mechanisms 4b installed on the surface of the rotating shaft 4a in a uniform and equidistant shape respectively. The uniform distributing mechanism 4b and the rotating shaft 4a are connected verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com