Thin-wall drill cylinder clamping device of thin-wall drill welding machine

A clamping device and thin-wall drill technology, which is applied in the field of machine tools, can solve the problems of occupying the space behind the V-shaped clamping block, affecting the installation of other devices, and the long time required for adjustment, so as to ensure the installation space of brazing heating equipment Or laser welding equipment installation space, improve production efficiency, reduce the effect of occupying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

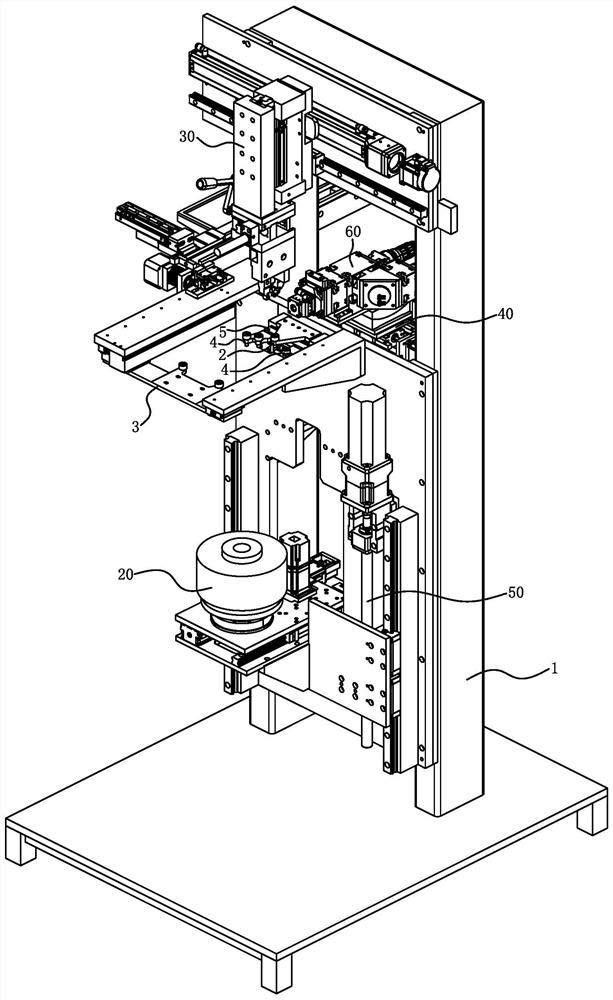

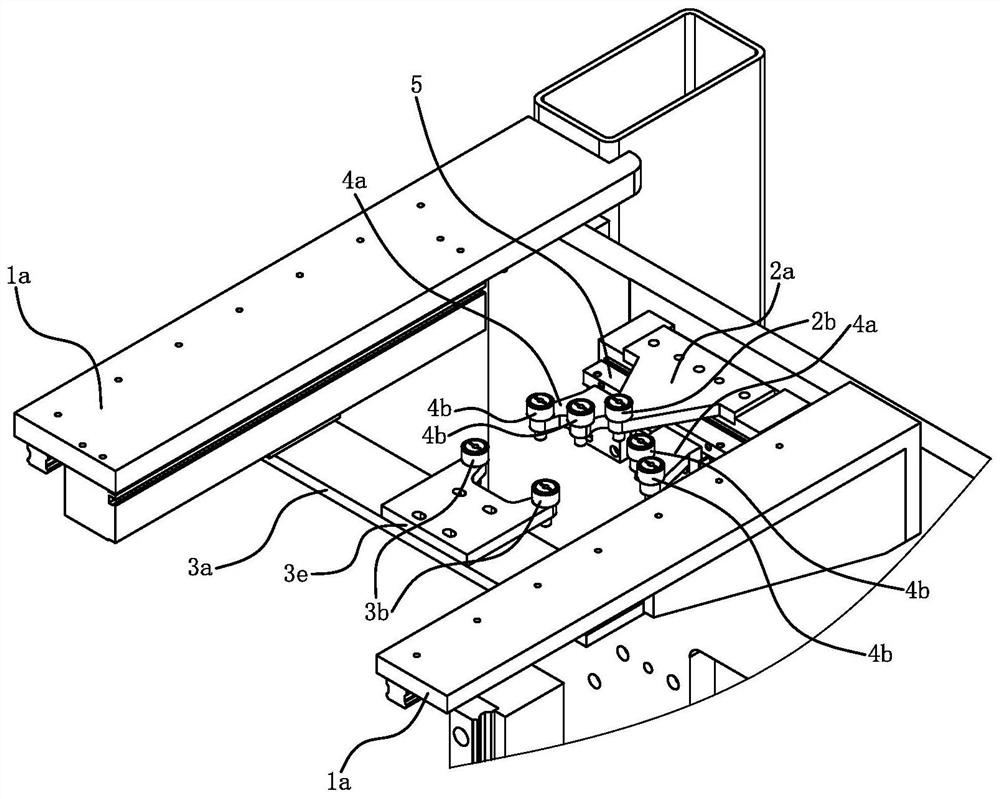

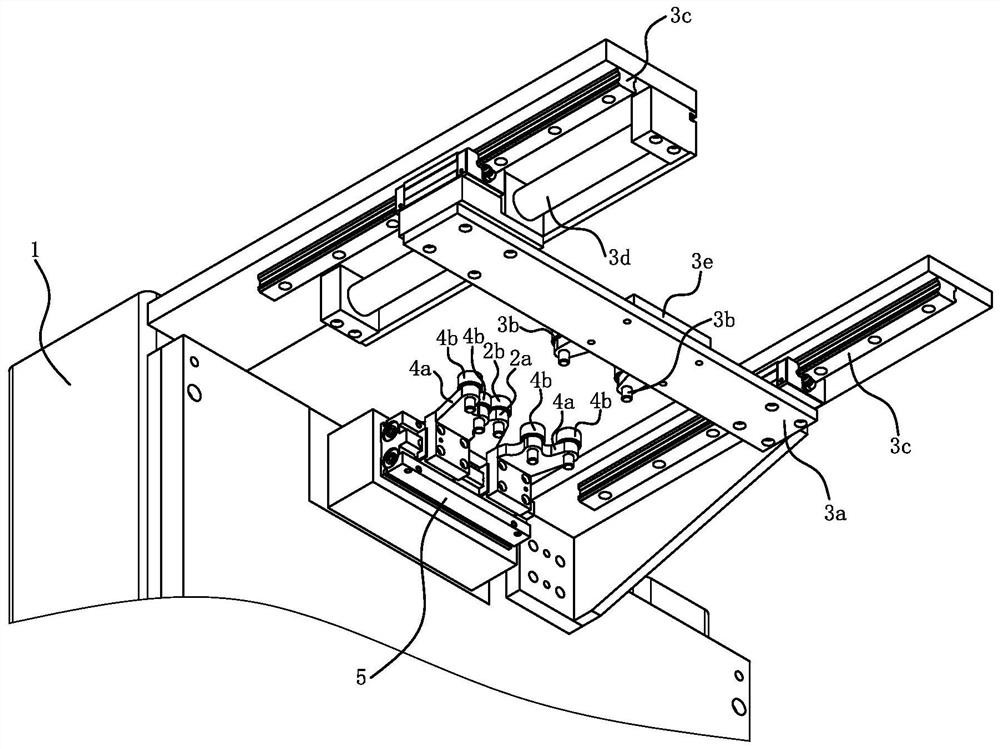

[0028] Embodiment one: if Figure 1 to Figure 3 As shown, the thin-walled drill welding machine includes a frame 1, a cylinder indexing and rotating device 20, a thin-walled drill cylinder 10 clamping device, a cutter head clamping device 30 and a laser head driving device 40; the cylinder indexing and rotating device 20 is connected with the frame 1 through the lifting mechanism 50, and the thin-walled drill cylinder clamping device and the cutter head clamping device 30 are all installed on the frame 1; the cylinder indexing and rotating device 20, the thin-wall drill cylinder clamping The device and the cutter head clamping device 30 are arranged sequentially from bottom to top. When the thin-walled drill cylinder 10 is vertically installed on the cylinder indexing and rotating device 20 , the thin-walled drill cylinder clamping device can clamp the top of the thin-walled drill cylinder 10 . The laser head driving device 40 is positioned at the rear side of the thin-walled...

Embodiment 2

[0037] Embodiment 2: The structure and principle of this embodiment are basically the same as those of Embodiment 1. The basic similarities are no longer redundantly described, and only the differences are described. The difference lies in: the rear side backer 4 and the frame 1 The connection structure and the use of different driving parts, the rear side backers 4 are connected with the frame 1 through the second guide rail, the frame 1 is rotatably connected with a synchronous gear, and the two rear side backers 4 are connected with Gear racks that mesh with each other. The number of driving parts is one group, and the driving parts are springs or cylinders; the two groups of rear side mounts 4 are connected through the driving parts. According to the actual situation, the quantity of the driving parts can also adopt two groups, so the two groups of rear side backers 4 are connected with the two groups of driving parts in one-to-one correspondence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com