Self-propelled revolving water conservancy engineering pipeline rust removal device

A water conservancy engineering and turnover technology, applied in grinding drive devices, manufacturing tools, grinding workpiece supports, etc., can solve problems such as pipeline corrosion, increase labor intensity of staff, power supply stability and insufficient power protection protection, etc. The power supply is continuous and stable, the grinding efficiency and quality are improved, and the practicality is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

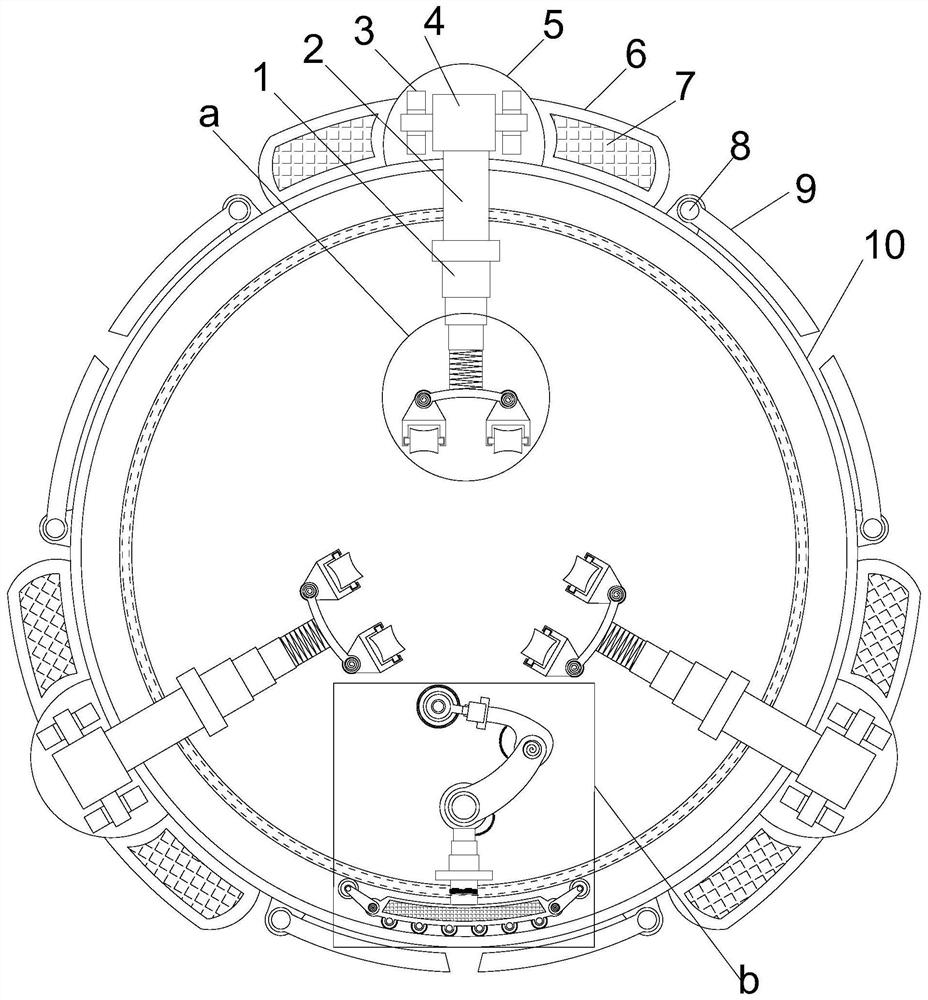

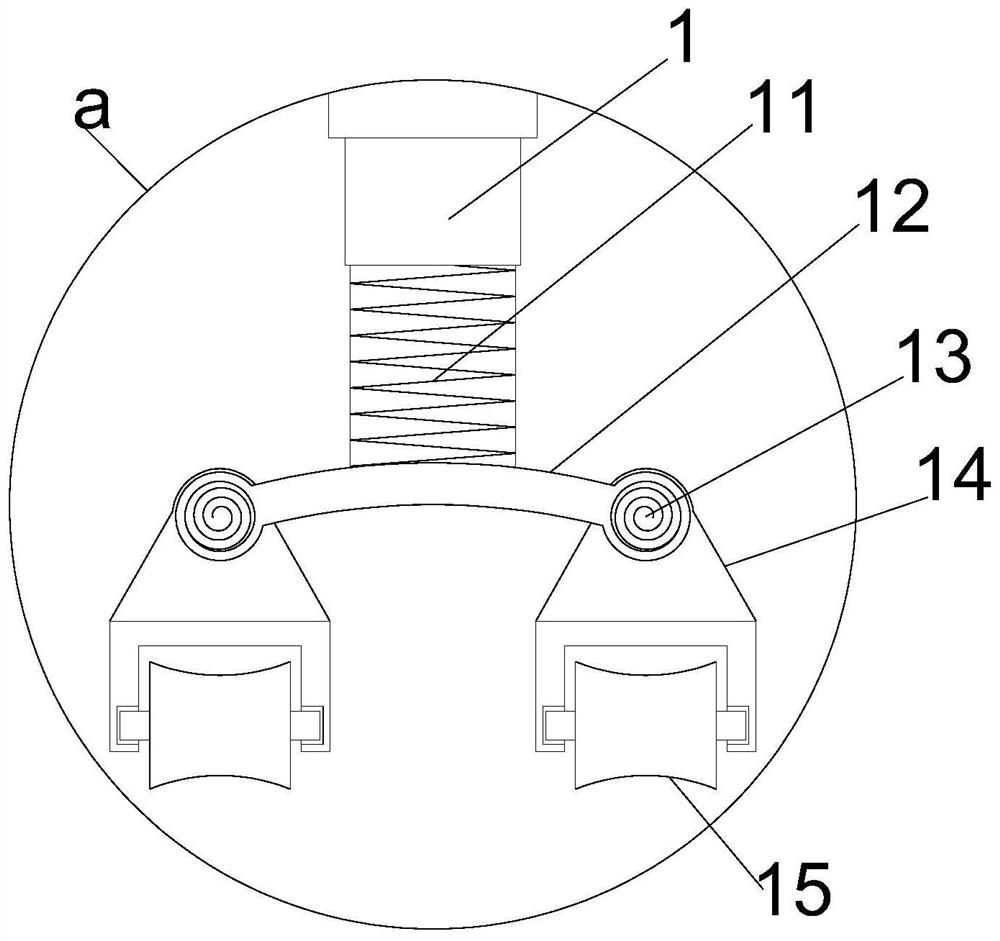

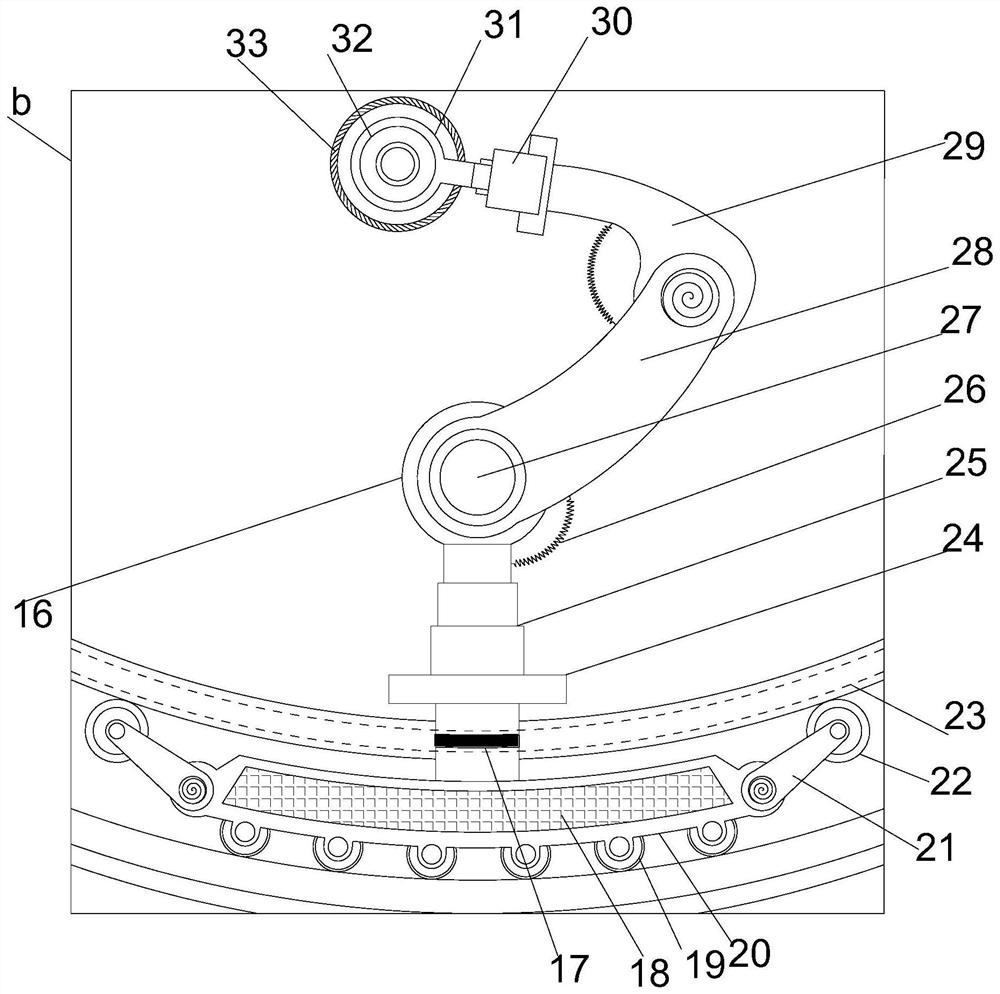

[0022] see Figure 1~4 , in an embodiment of the present invention, a self-propelled round-type water conservancy engineering pipeline derusting device includes a vertically arranged support guide cylinder 10, and a plurality of support installation plates 5 are arranged at equal angles on the outside of the support guide cylinder 10, and adjacent support installation plates The outer sides of the support and guide cylinders 10 between 5 are symmetrically provided with rotating support plates 9, and the rotating support plates 9 are all fixed on the outside of the support and guide cylinders 10 by driving the rotating shaft 8, and the support and guide cylinders 10 on both sides of the support installation plate 5 Both are provided with a supporting installation cover 6, and the interior of the supporting installation cover 6 is embedded with a battery 7, and the front end of the supporting installation plate 5 is symmetrically provided with a rotating mounting frame 3, and the...

Embodiment 2

[0025] On the basis of Embodiment 1, through the telescopic adjustment of the displacement telescopic column 25, the device can adapt to the rust removal operation of pipelines with different diameters, and the circular conductive groove 23 cooperates with the rotating conductive block 17 to make the arc-shaped mobile plate 20 In the shifting type, stable power supply is maintained all the time, and the split battery 18 can guarantee to provide electric energy when the power is cut off, so that the device is reset and the working grinding disc 33 is protected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com