High-efficiency water delivery multi-stage fire pump

A fire pump, high-efficiency technology, applied to pumps, parts of pumping devices for elastic fluids, piston pumps, etc., can solve the problems of complex design structure, unfavorable flexible use, and complicated water diversion links of multi-stage fire pumps, and achieve Strong self-absorbing effect, enhancing the effect of amplification, and accelerating the effect of forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

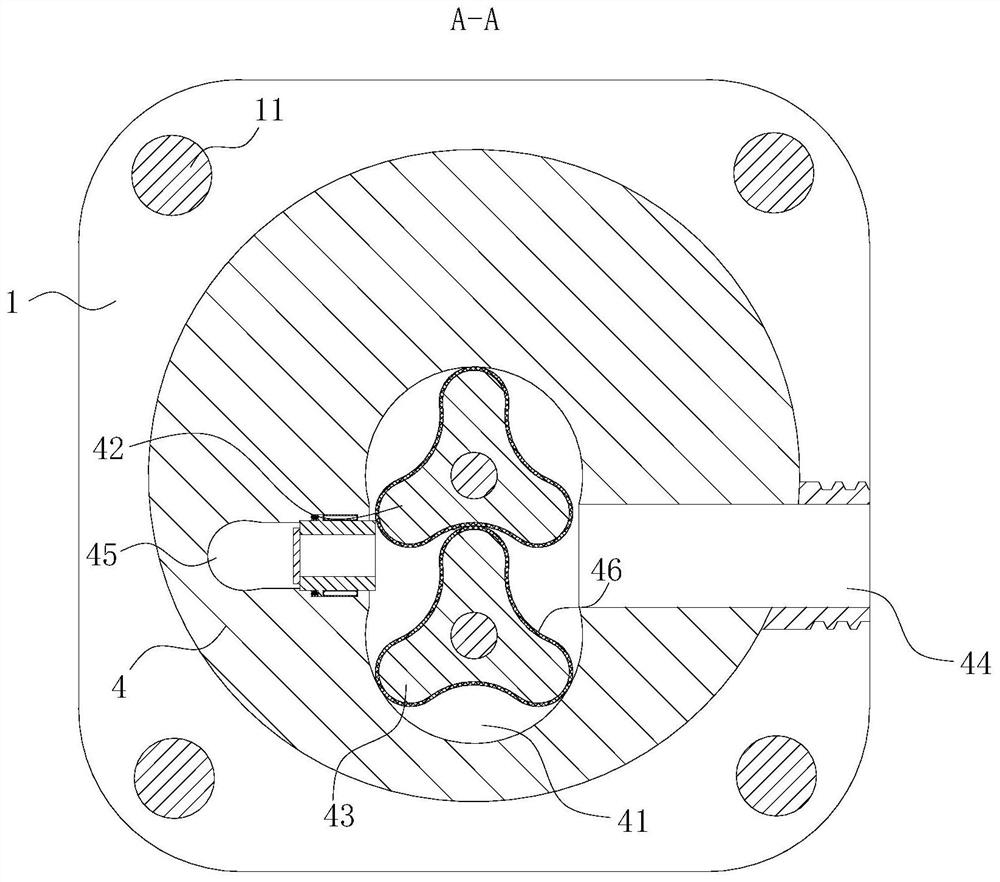

[0027] As an embodiment of the present invention, a first chute 6 is opened in the first through groove 45; a piston 61 is slidably connected to the first chute 6; the piston 61 is designed in a "ten" shape; The side of the first chute 6 away from the first cavity 41 is elastically connected to the piston 61; the inside of the piston 61 is provided with a second through groove 62; the second through groove 62 is designed to pass through the piston 61; The side of the piston 61 away from the first cavity 41 is hinged with a sealing cover 63; the sealing cover 63 has a circular design and the diameter of the sealing cover 63 is larger than the diameter of the second through groove 62;

[0028] Because the first cam 42 and the second cam 43 have a certain gap for the extraction of air when they are dry-running, the vacuuming progress of the self-absorbing water operation is not fast enough, and its work preparation time has a delay. During work, the first cam 42 The second cam 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com