Three-D parallel translation mechanism for virtual axle NC machinetool, robot and mechanical measurer

A technology of CNC machine tools and virtual axes, applied in the directions of manipulators, metal processing machinery parts, automatic control devices, etc., can solve the problems of complex error analysis and correction, simple structure, small working space, etc., and achieve simplified positive solutions and correction compensation analysis problems. , the mechanism is simple, the rigidity is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

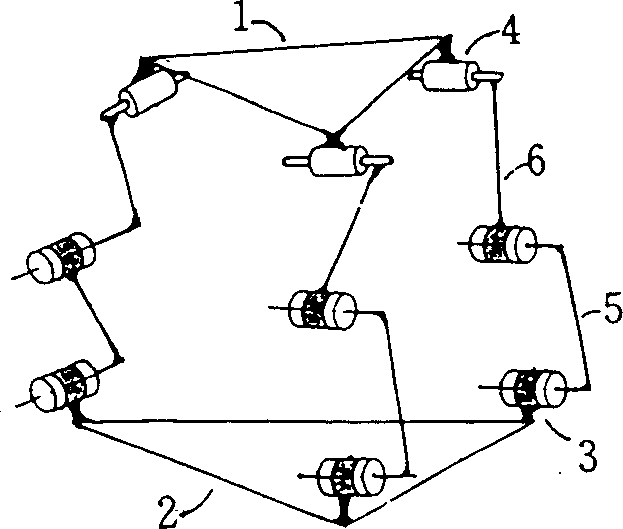

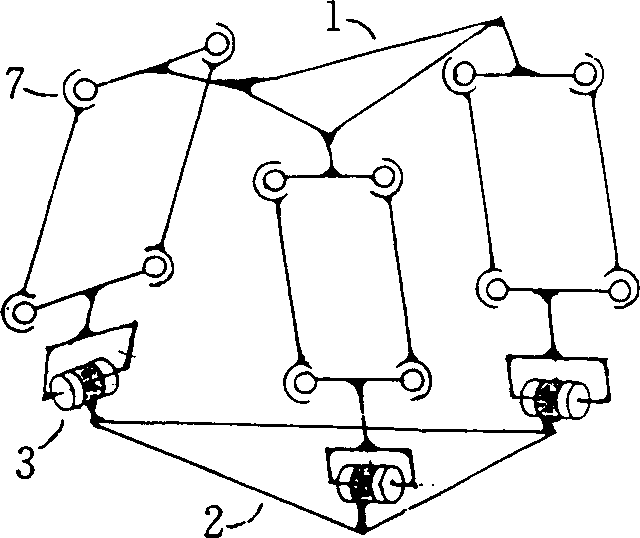

[0026] attached Figure 8 Shown is an embodiment of the invention applied to a virtual axis mechanical measuring machine. Install the measuring head (5) on the moving platform (1), install the measured workpiece (6) on the static platform (2) (base), and drive the three rotating pairs on the base (2) to control the moving platform The position of the upper measuring head (5) in space (three-dimensional movement) is completed to complete the specified measuring process. If will attach Figure 8 The measurement head (5) on the moving platform (1) is replaced by a manipulator gripper, which can also be regarded as an embodiment of the present invention for an assembly robot that only needs three-dimensional translation.

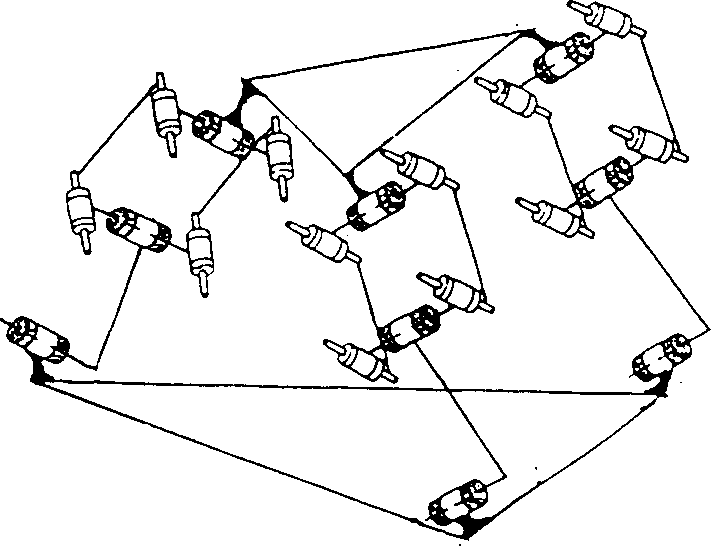

[0027] In a word, the present invention provides a new model with the above-mentioned characteristics for virtual axis CNC machine tools, walking (including crawling, wall climbing, etc.) robots, industrial robots (such as assembly and stacking robots) and vir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com