Small thermal gas mass flow meter

A gas mass flow and thermal technology, applied in indirect mass flowmeters, mass flow measurement devices, etc., can solve problems such as difficulty in application, and achieve the effects of simple structure, convenient use and operation, and increased analysis functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A small thermal gas mass flowmeter, including a housing, a circuit assembly, and a sensor assembly;

[0034] The above-mentioned circuit device includes a speed sensor, a temperature sensor, a signal acquisition module, a signal processing control module, a button module, a display module, a communication module, an output module, a power detection module, a sensor power module, a power module and a battery;

[0035] The speed measuring sensor and the temperature measuring sensor are respectively electrically connected to the signals of the signal acquisition module; the signal acquisition module, the button module, the display module, the communication module, the output module, the power detection module, and the sensor power module are respectively electrically connected to the signals of the signal processing control module; The communication module is electrically connected with the signal processing control module for bidirectional signals; the power supply module ...

Embodiment 2

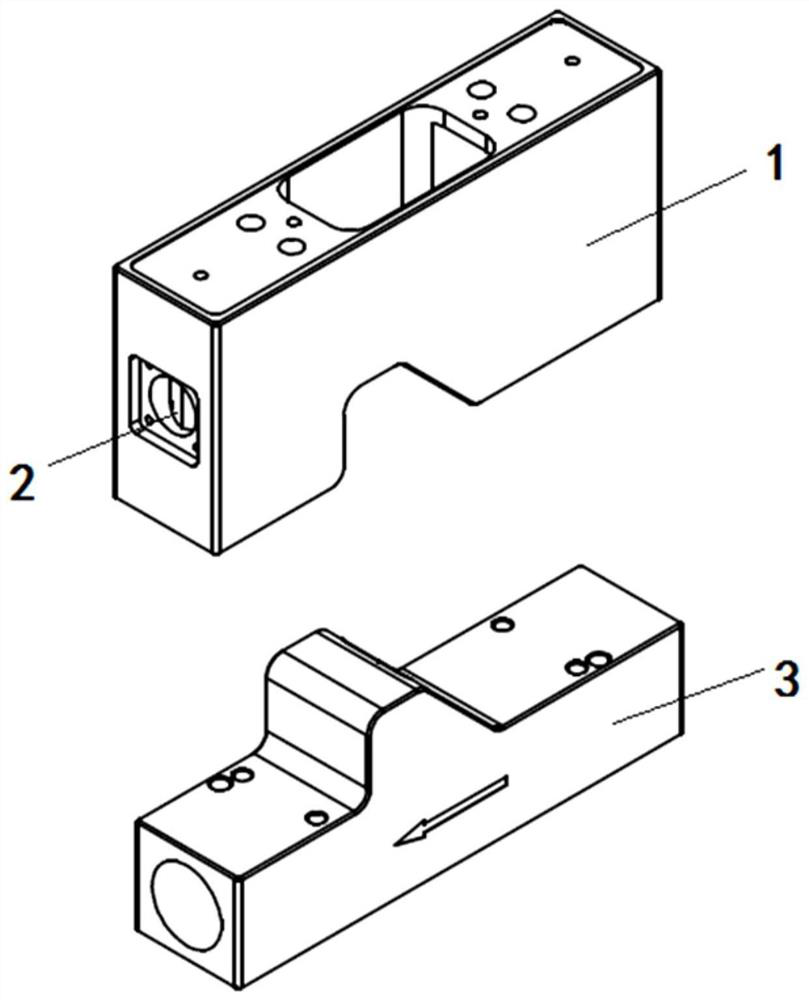

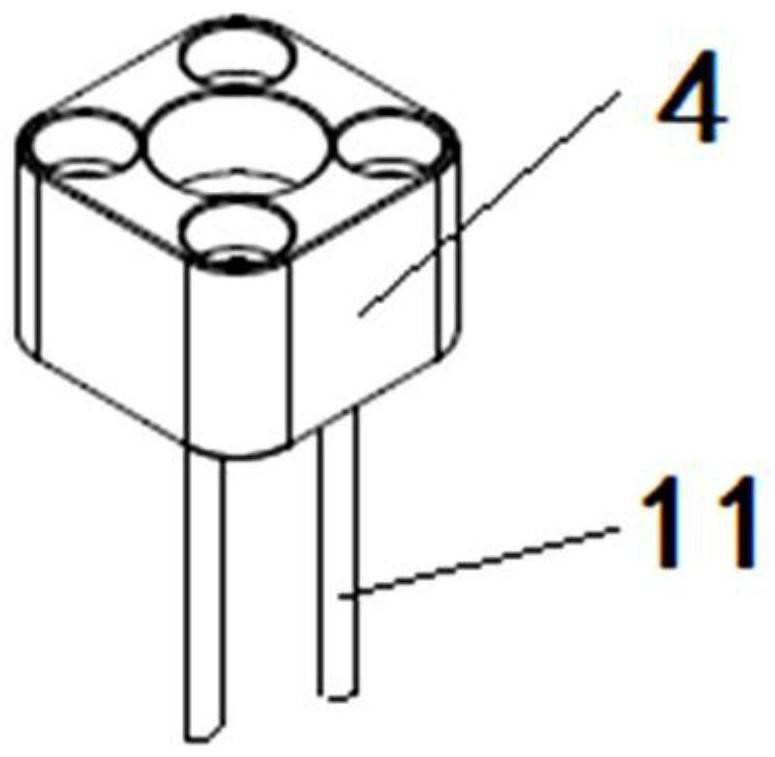

[0040] Small thermal gas mass flow meters, such as Figure 1~4 As shown, it is mainly composed of a casing, a circuit device, and a sensor device.

[0041] The shell is mainly composed of an upper shell 1 and a lower shell 3 .

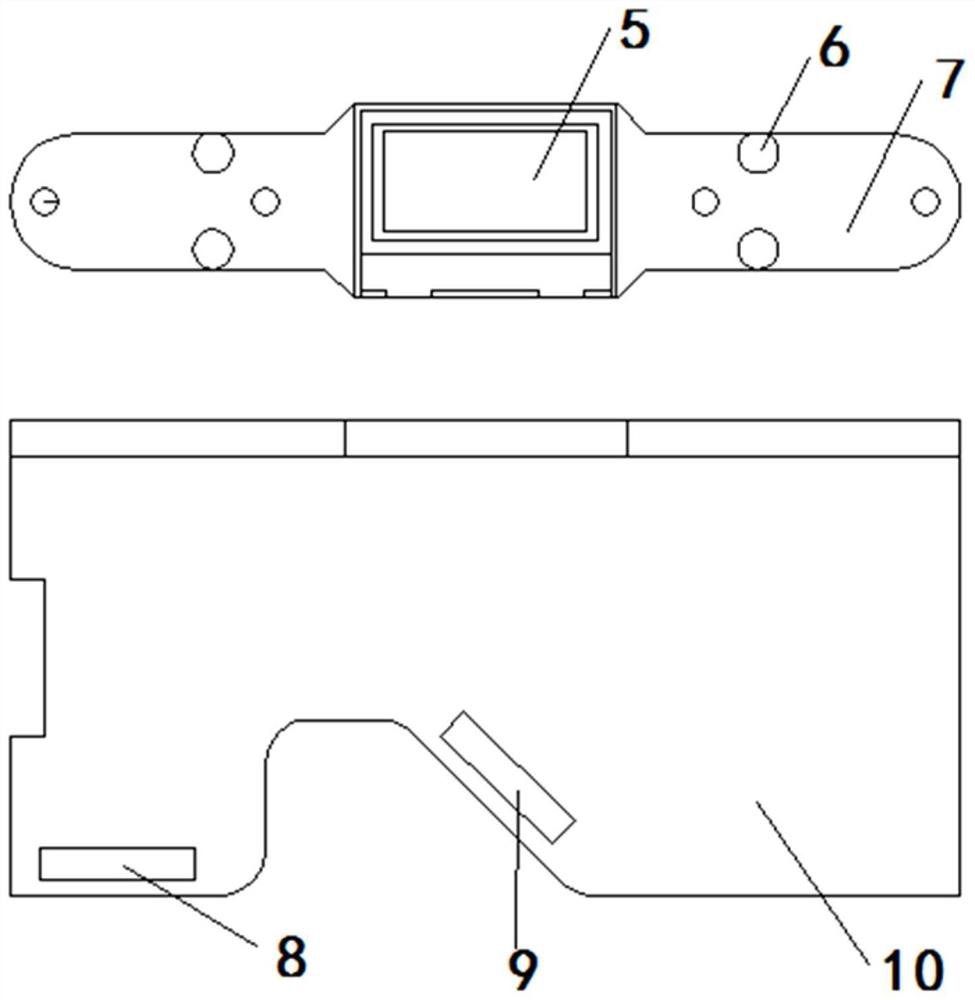

[0042] The circuit device is mainly composed of a power module 12, a sensor power module 13, a signal acquisition module 16, a signal processing control module 17, a button module 18, a display module 19, a communication module 20, an output module 21, a power detection module 22, and a power supply 23.

[0043] The display module 19 is used for real-time display of measured values, inquiry of stored values of measured values, indication of working status and prompt of faults.

[0044] The button module 18 is used for parameter setting and data query date setting.

[0045] The signal acquisition module 16 receives the output signals of each sensor, filters and amplifies the signals, converts them into voltage signals, and transmits them to the sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com