Tobacco shred structure detection method based on image processing

An image processing and shredded tobacco structure technology, which is applied in the field of shredded tobacco structure detection based on image processing, can solve the problems of poor objectivity of evaluation, high labor intensity, and many human factors, so as to reduce the requirements of hardware equipment and reduce the complexity of algorithms Degree, the effect of reducing the amount of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose, a method for detecting the shredded tobacco structure based on image processing proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred examples.

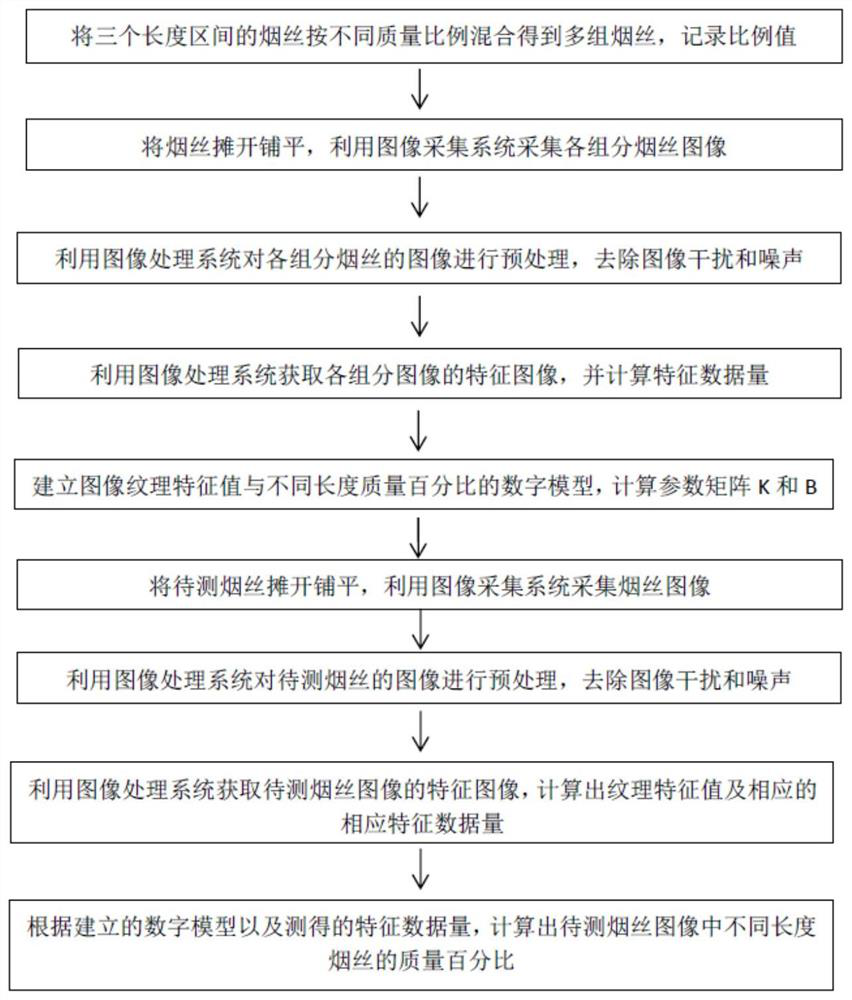

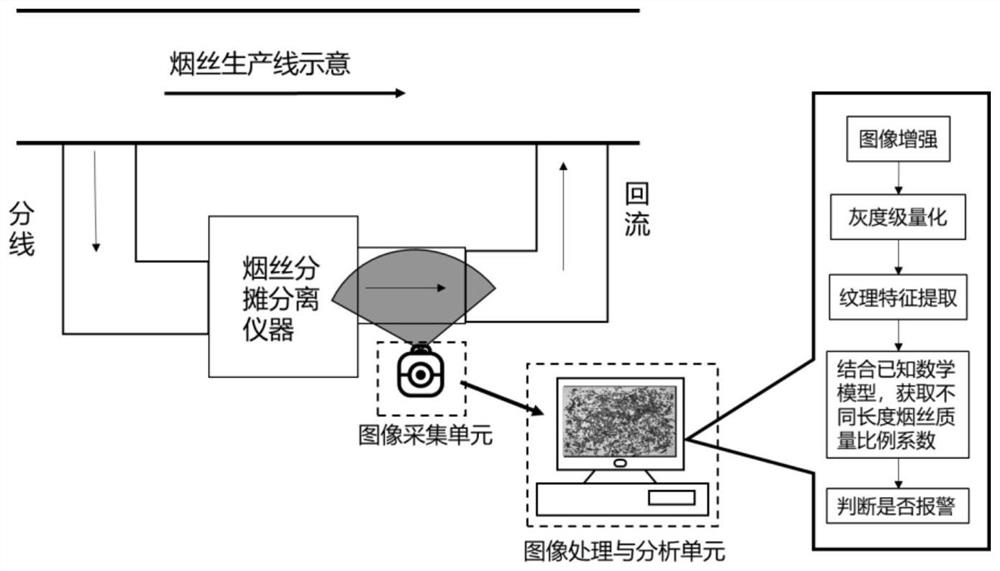

[0031] An image processing-based tobacco structure detection method, please refer to figure 1 , figure 2 , including the following steps:

[0032] A Select multiple groups of shredded tobacco arbitrarily, and record the mass ratio a of shredded tobacco with a length greater than 3 mm, the mass ratio b of shredded tobacco with a length between 1 mm and 3 mm, and the mass ratio c of shredded tobacco with a length of less than 1 mm in each group of shredded tobacco. The mass ratios a, b, and c of different lengths of shredded tobacco in the shredded tobacco satisfy a+b+c=100.

[0033] B Utilize the image acquisition syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com