Method for quickly compiling aircraft assembly process file

A technology for process documents and aircraft assembly, applied in the directions of image data processing, special data processing applications, 3D modeling, etc., can solve the problems of planning assembly process and difficulty in forming assembly process knowledge base, so as to improve compilation efficiency and quality, The effect of improving work efficiency and work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

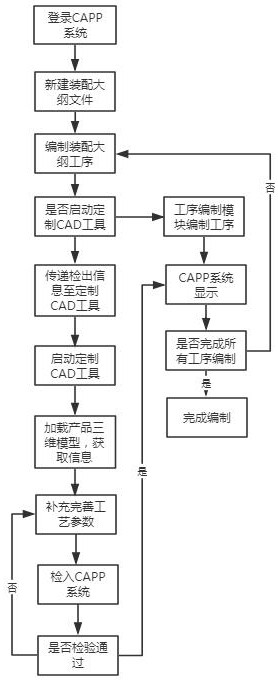

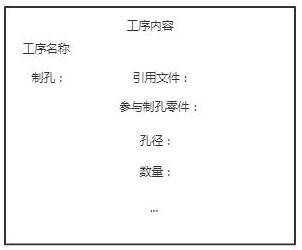

[0042] The present invention is realized through the following technical solutions, as figure 1 , figure 2 , image 3 As shown in the figure, a method for quickly compiling aircraft assembly process documents integrates the CAD software installed with custom CAD tools with the CAPP system, uses the custom CAD tools to extract the 3D model information of the product, and forms the 3D model information into XML according to the standard process parameter format. process text, and then import the XML process text into the CAPP system to realize the transmission and interaction of process information.

[0043] Use the CAPP system to call the CAD software that has installed the custom CAD tool to obtain the 3D model information of the product in batches. The custom CAD tool will organize the 3D model information of the product and form the process text in the XML file format; finally, the process text in the XML file format is uploaded in CAD Process information is transmitted a...

Embodiment 2

[0046] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 As shown, further, in order to better realize the present invention, the customized CAD tool is secondary development based on CAA-based CATIA, by traversing the 3D model of the product at the specified location, extracting the information required to compile the assembly process file.

[0047] It should be noted that, through the above improvements, the information required to compile the assembly process documents includes the assembly drawing number, standard part information, assembly annotation information, and so on.

[0048] Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

Embodiment 3

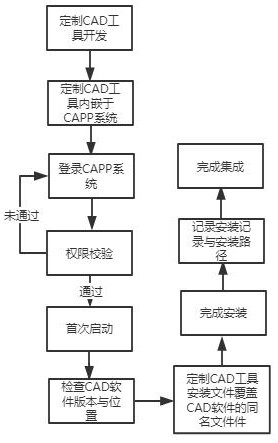

[0050] This embodiment is further optimized on the basis of the above embodiments, such as image 3 As shown, further, in order to better realize the present invention, the integration of the customized CAD tool and the CAPP system specifically includes the following steps:

[0051]Step SA1: Embed the customized CAD tool installation file in the CAPP system; the customized CAD tool installation file is the WIN_b64 or Intel_a folder corresponding to the CATIA software version;

[0052] Step SA2: Log in to the CAPP system, and after the login permissions are verified to be consistent, start the customized CAD tool in CAPP, and overwrite the folder with the same name in the local CAD software with the customized CAD tool installation file; complete the installation of the customized CAD tool on the CAD software .

[0053] Step SA3: Record the user's installation record and the installation path of the customized CAD tool in the CAPP system; complete the integration.

[0054] It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com