Waste oil emulsion chaotic frequency pulsed electric field demulsification method and system

A frequency pulse, high-voltage pulse electric field technology, applied in the direction of electricity to separate liquids, lubricating compositions, etc., can solve the problems that the constant pulse electric field cannot cover the resonance frequency of emulsified oil, and the harmonic resonance frequency of droplets is uncertain and inconsistent. Achieve the effect of high-efficiency demulsification and dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

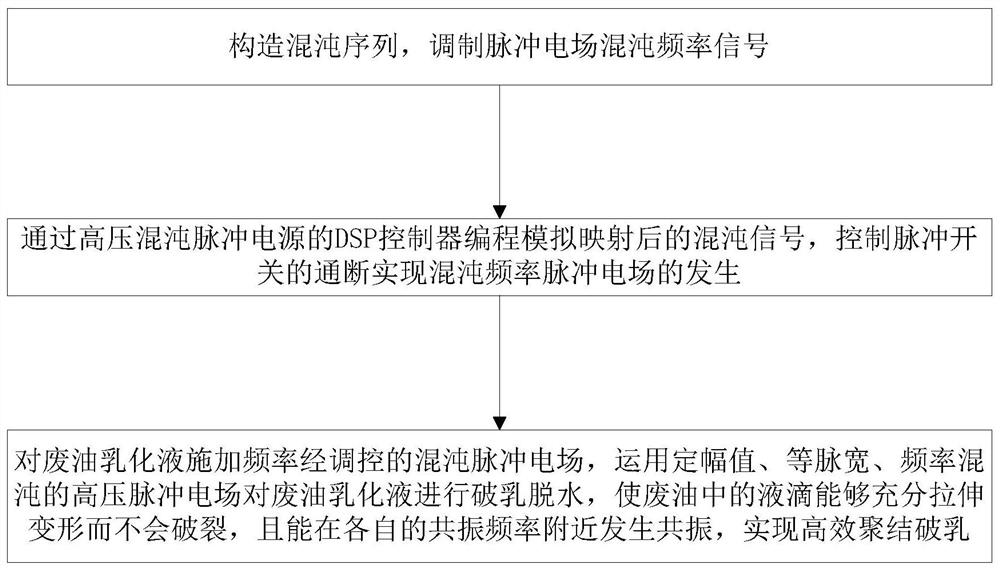

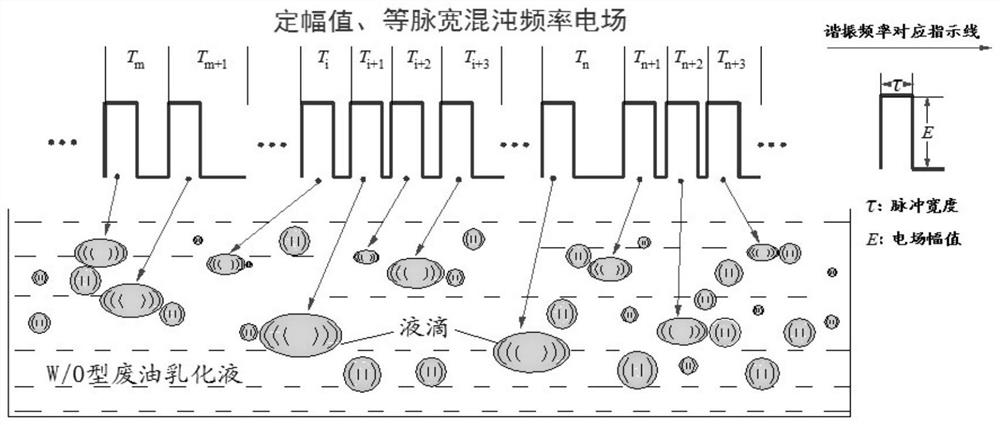

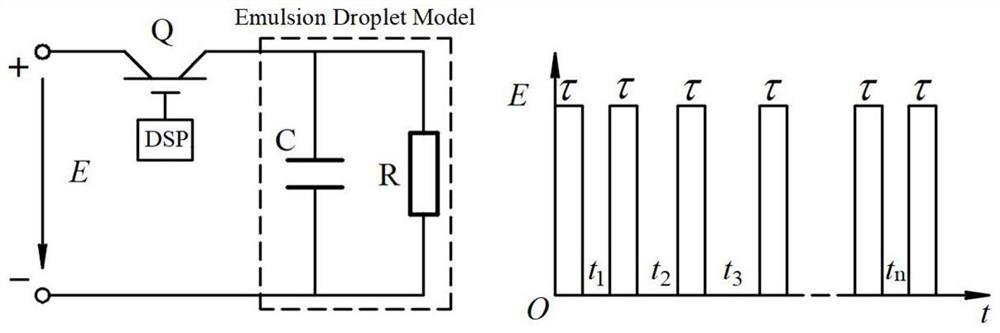

[0058] Such as figure 1 as shown, figure 1 It is a schematic diagram of a chaotic frequency electric field exciting droplet resonance in oil. This embodiment provides a method for demulsifying waste oil emulsion with a chaotic frequency pulse electric field. The basic idea of this method is:

[0059] Construct a chaotic sequence and modulate the chaotic frequency signal of the pulsed electric field; program and simulate the mapped chaotic signal through the DSP controller of the high-voltage chaotic pulsed power supply, and control the on-off of the pulse switch to realize the occurrence of the chaotic frequency pulsed electric field;

[0060] Apply a frequency-regulated chaotic pulse electric field to the waste oil emulsion, and use a constant amplitude, equal pulse width, and frequency chaotic high-voltage pulse electric field to demulsify and dehydrate the waste oil emulsion, so that the droplets in the waste oil can be fully stretched Deformation without cracking, and can...

Embodiment 2

[0104] This embodiment provides a waste oil emulsion chaotic frequency pulse electric field demulsification system, including a waste oil emulsion parameter unit, a demulsification electric field parameter generation unit, a frequency chaotic high-voltage pulse electric field generator and a control regulator;

[0105] The waste oil emulsion parameter unit is used to obtain physical parameters of the waste oil emulsion;

[0106] The demulsification electric field parameter generation unit is used to calculate the amplitude and pulse width of the demulsification electric field suitable for waste oil emulsion;

[0107] The frequency chaotic high-voltage pulsed electric field generator is used to generate a frequency chaotic high-voltage pulsed electric field with a constant amplitude and equal pulse width;

[0108] The control regulator is used to control the effect of the frequency chaotic high-voltage pulse electric field generator on the waste oil emulsion, so as to be suitab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com