Precise gas adsorption system for programmed temperature desorption

A technology of programmed temperature rise and gas adsorption, which is applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems that the uniformity of adsorption cannot be guaranteed, and the gas adsorption cannot be accurately controlled, so as to improve the applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the embodiments and the accompanying drawings. The following examples are only used to illustrate the present invention, but are not intended to limit the scope of the present invention.

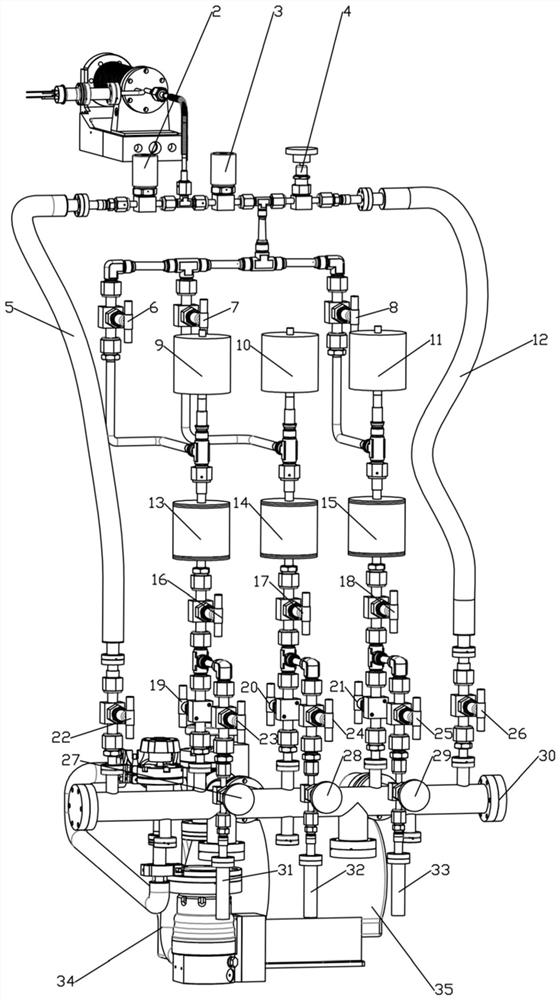

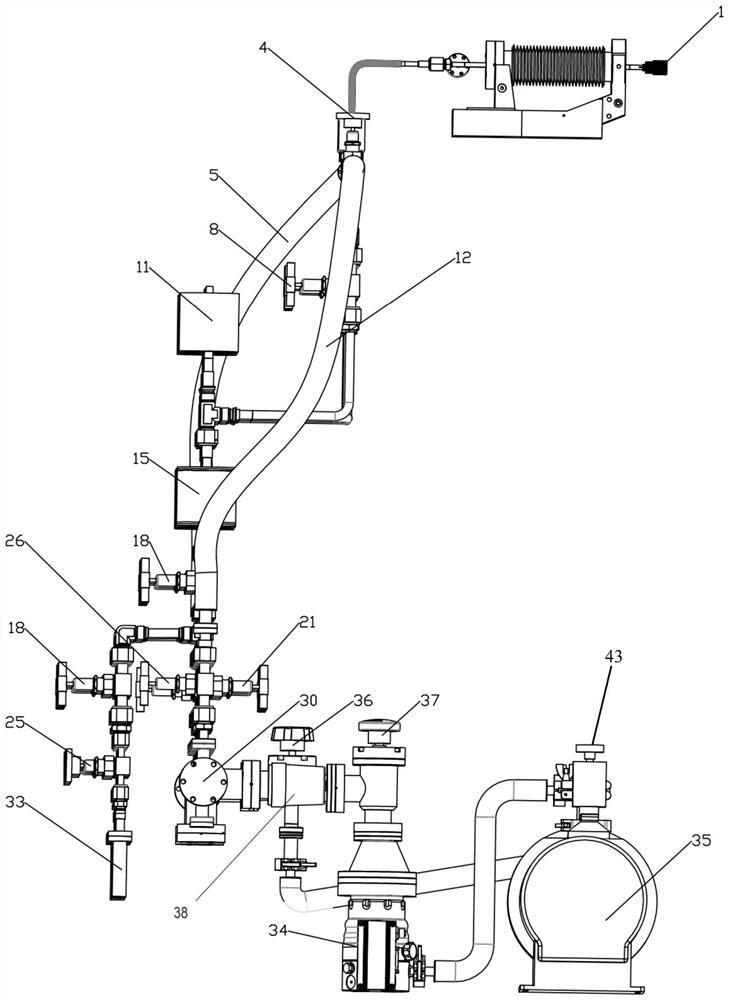

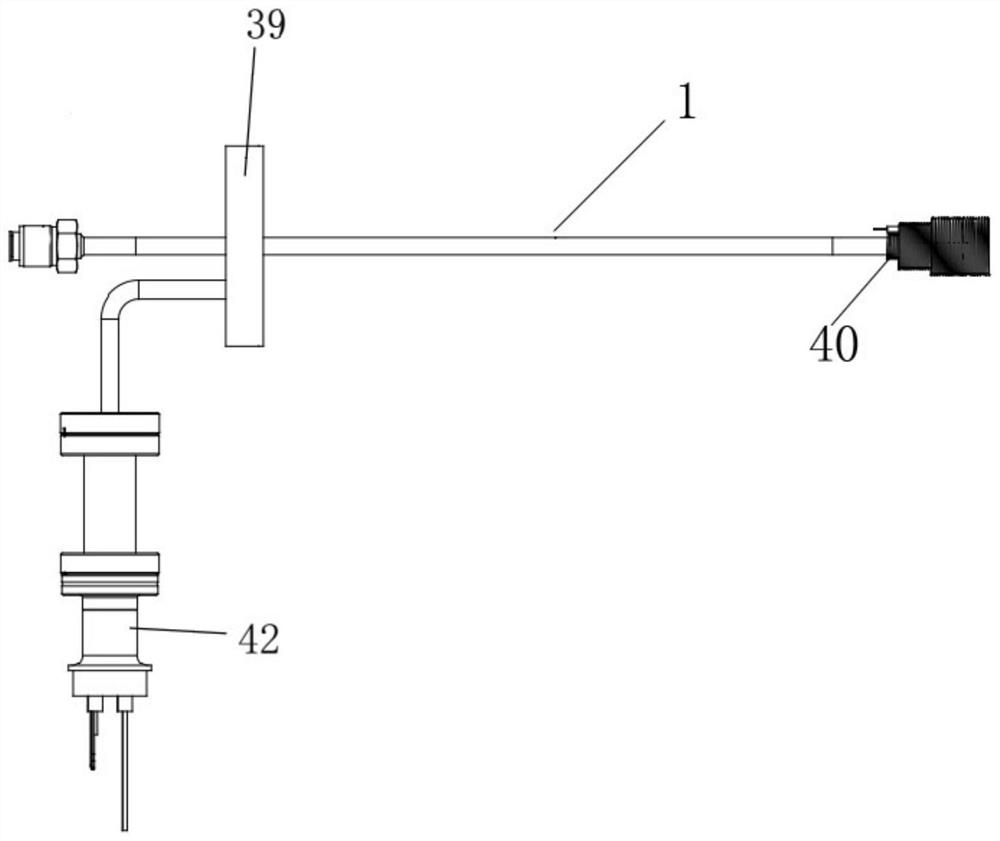

[0029] A sophisticated gas adsorption system for temperature programmed desorption, such as Figure 1-4 As shown, including vacuum subsystem, gas path subsystem and gas sampling head,

[0030] The vacuum subsystem includes a backing pump 35, a vacuum pump 34, a vacuum chamber, and a vacuum gauge 38. The backing pump 35 can be a dry backing pump, and the vacuum pump 34 can be a molecular pump. The backing pump 35 and the vacuum pump 34 pass Fore-stage pump valve 43, pipeline connection, fore-stage pump 35 is connected with vacuum chamber through fore-stage pump valve 43, pipeline, valve 36, and vacuum pump 34 is connected with vacuum chamber through vacuum pump valve 37, pipeline; Vacuum chamber is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com