Anti-corrosion spraying device for automobile sealing strip

A technology for automotive sealing strips and anti-corrosion spraying, which is applied to spray devices, devices for coating liquid on surfaces, coatings, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

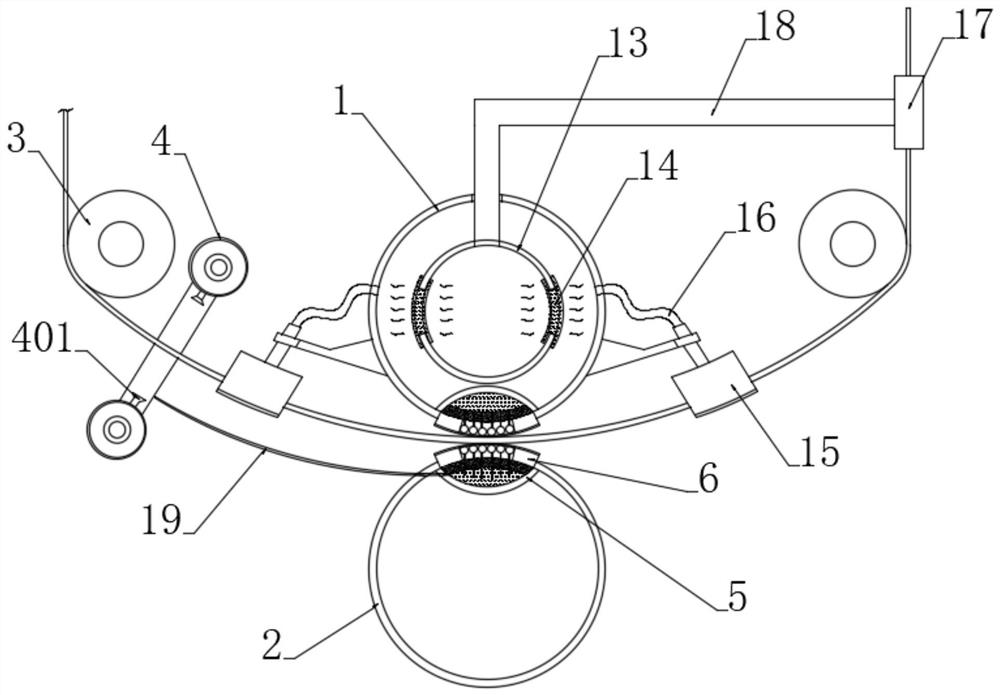

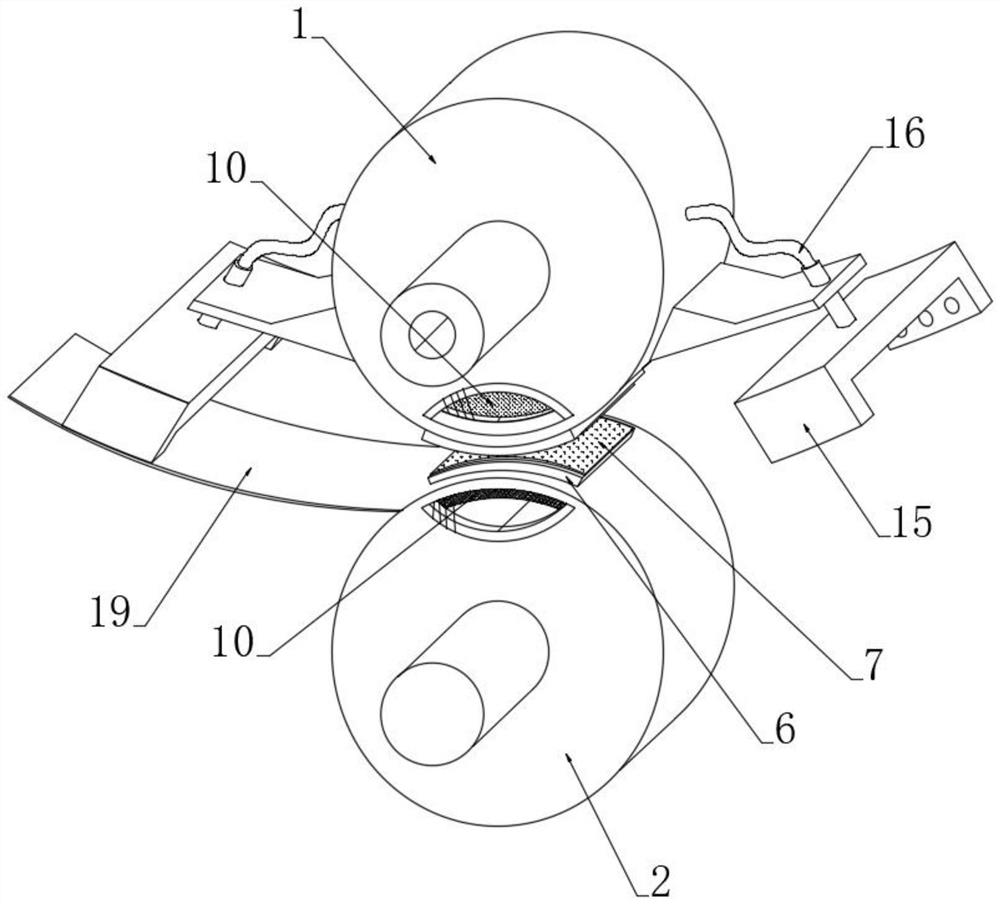

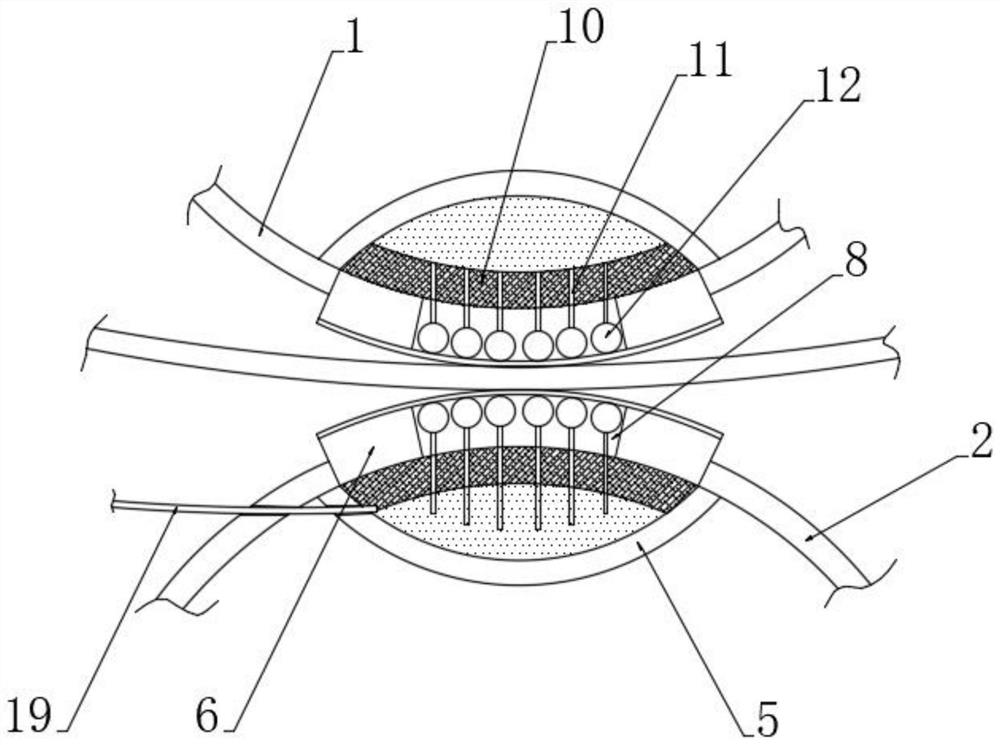

[0037] see Figure 1-2 , an anti-corrosion spraying device for automobile sealing strips, comprising an upper fixed roller 1 and a lower fixed roller 2 arranged up and down, and rotating guide rollers 3 for sealing strip conduction are symmetrically distributed on the left and right sides of the upper fixed roller 1, and the sealing strip Through the connection between the upper fixed roller 1 and the lower fixed roller 2, a pair of spraying cylinders 4 arranged obliquely are arranged under one side of the left end rotating guide roller 3, and the opposite sides of the pair of spraying cylinders 4 are equipped with atomizers. Spraying nozzle 401, the atomizing spraying nozzle 401 distributed up and down is distributed on the upper and lower sides of the sealing strip, and the two spraying cylinders 4 are symmetrically distributed up and down along the conveying direction of the sealing strip, and are used to carry out the upper and lower adjustment of the sealing strip during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com