Plate omni-directional cleaning device and plate cleaning process

A cleaning equipment and all-round technology, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve the problem of difficult to remove dust, glue, dirt, poor quality, and different specifications of the board surface. and other problems, to achieve the effect of reducing equipment production and operation costs, saving manpower and material resources, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

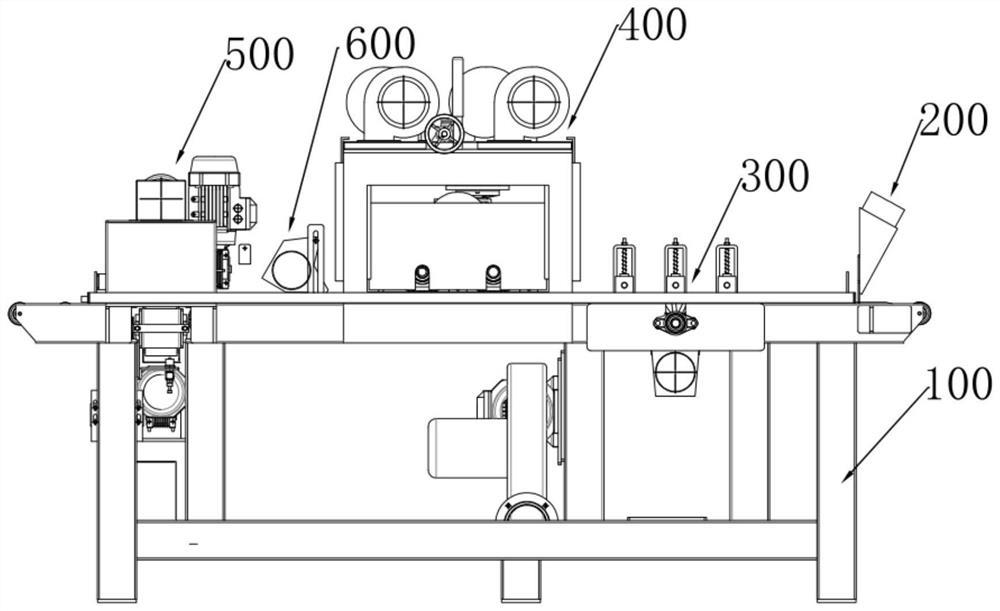

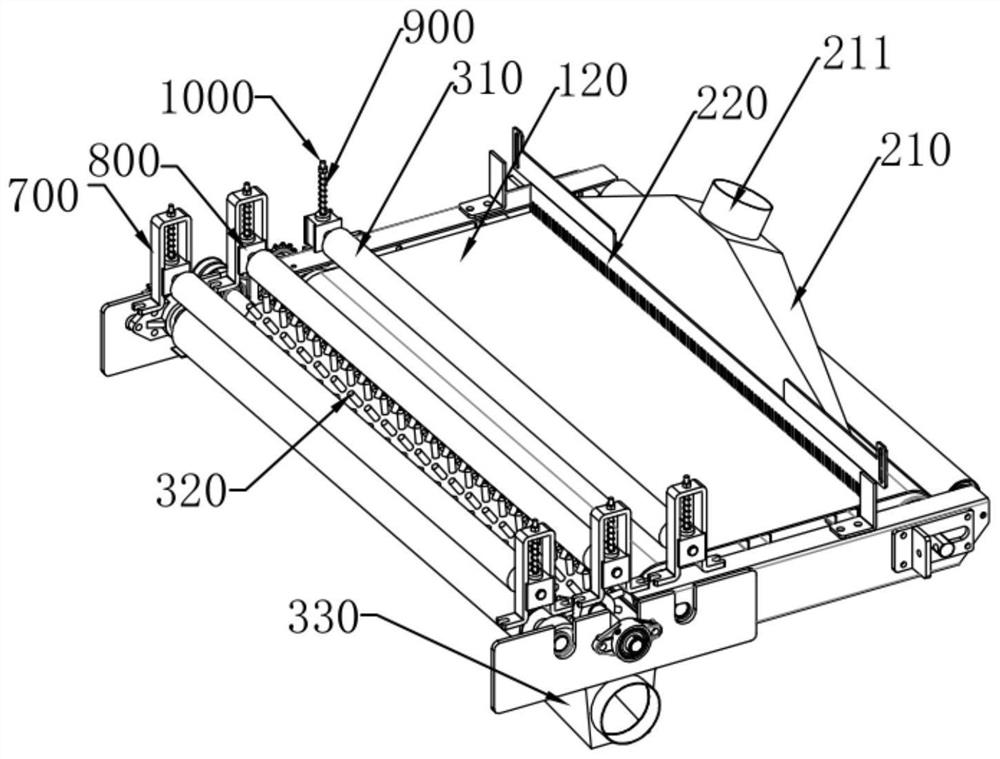

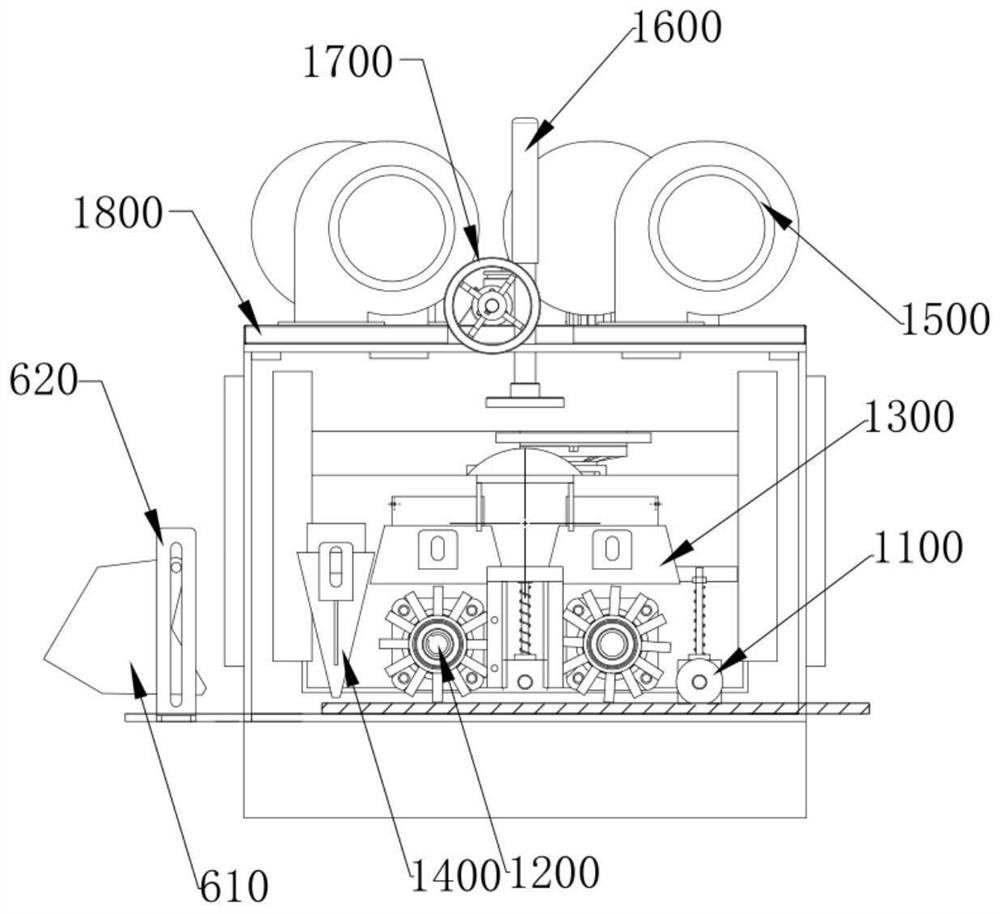

[0047] Such as Figure 1 to Figure 5 As shown, this embodiment provides an all-round board cleaning equipment for multiple cleaning of boards, mainly including a transport assembly 100, a preliminary cleaning assembly 200, a lower surface cleaning assembly 300, an upper surface cleaning assembly 400 and a wet cleaning Component 500. Among them, the conveying assembly 100 is used for continuously transporting the boards, so that the boards can be automatically transported to the corresponding cleaning area, and the preliminary cleaning assembly 200 for preliminary cleaning of the boards can preliminarily intercept the boards and absorb and collect large particles of dust on the surface of the boards and other Debris: The lower surface cleaning component 300 and the upper surface cleaning component 400 can successively clean all kinds of dust adherents on the lower surface and the upper surface of the board, and then pass through the wet cleaning component after the unified reco...

Embodiment 2

[0056] This embodiment provides a board cleaning process utilizing board omni-directional cleaning equipment, which specifically includes the following steps:

[0057] Step 1. Interception and cleaning: the plate is input by the first conveyor belt 120 of the transmission assembly 100, and the preliminary cleaning assembly 200 is opened to intercept, clean and adsorb the dust and adherents on the surface of the plate; in step 1, the remaining on the surface of the plate Processing waste and dust can be mostly retained by the retaining brush.

[0058] Step 2. Cleaning of the lower surface: After the sheet is transported to the lower surface cleaning assembly 300, adjust the pressing height of the first lower pressing roller 310 according to the thickness of the sheet, and the sheet will clean the dust and adherents on the lower surface of the sheet when the lower cleaning roller brush 320 rotates Collect it into the lower cleaning port. In step 2, the hard-to-retain adherents ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com