Adaptor connector automatic assembly and detection device and assembly and detection method thereof

A technology for automatic assembly and testing equipment, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of unguaranteed quality, affecting the quality of connectors, inconvenient moving and transmission, etc., to save processing space and equipment investment , The effect of saving equipment layout space and assembly space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solutions protected by the present invention will be specifically described below in conjunction with the accompanying drawings.

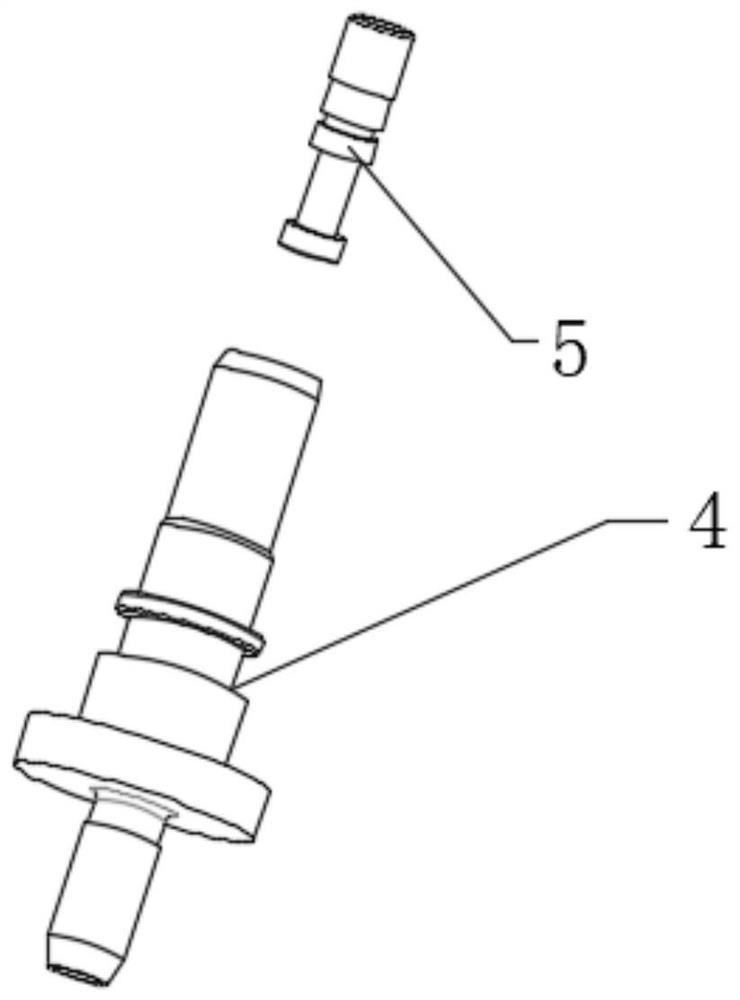

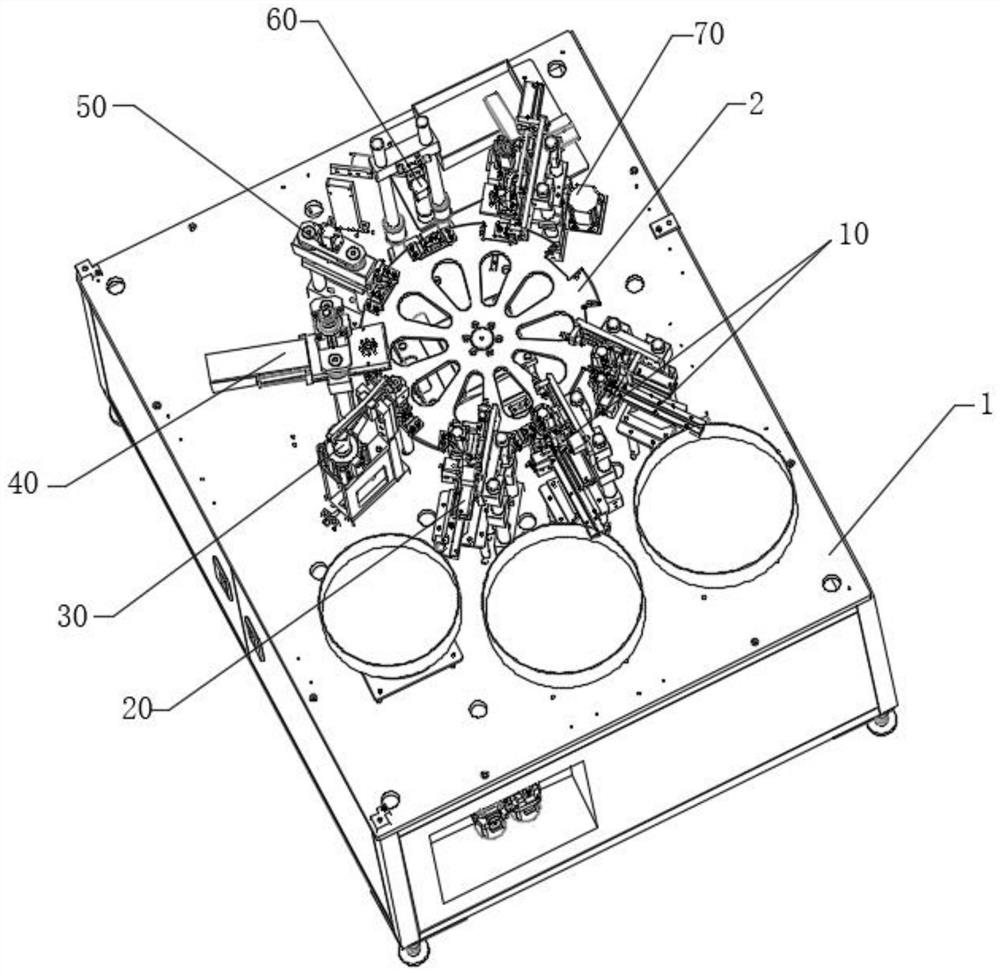

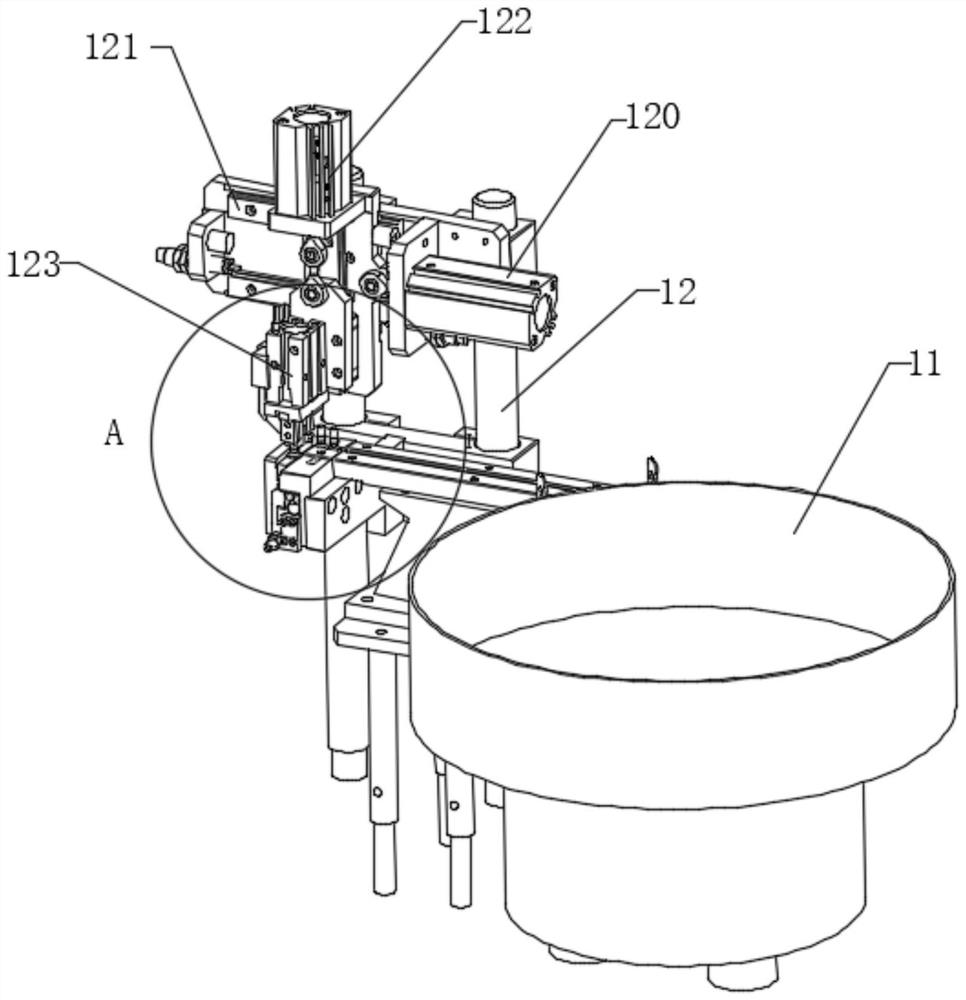

[0053] Please refer to Figure 1 to Figure 13 . The present invention proposes an automatic assembly and testing device for connector joints, which includes a machine platform 1, an indexing plate 2 is arranged on the machine platform 1, and a metal part feeding station, The insulator loading station, the first assembly station, the second assembly station, the first inspection station, the second inspection station and the blanking station are provided with reprinting fixtures 3 on each station, surrounding the The indexing plate 2 is sequentially provided with a metal parts feeding mechanism 10, an insulating parts feeding mechanism 20, an assembly mechanism, a first detection mechanism 50, a second detection mechanism 60 and a blanking detection mechanism 70, wherein the assembly mechanism includes The closing assembly 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com