Heat treatment process and tooling for shield machine cutter ring

A technology of shield machine and heat treatment equipment, which is applied in the field of construction machinery, can solve the problems of poor impact toughness of tool holders and improved toughness of tool holders, and achieve high impact toughness, reduce labor intensity of workers, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

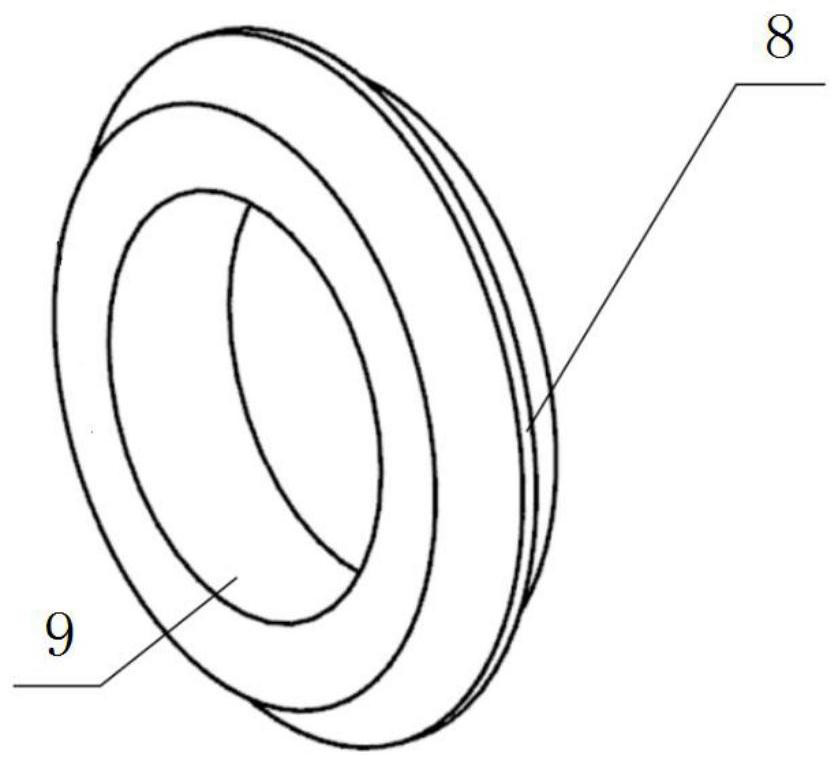

[0042] FIG. 2 illustrates the structure of the cutter ring 1. The knife ring 1 for this embodiment includes a knife edge 8 and a knife seat 9, and the knife seat 9

[0047] Further, after the tempering is completed, the cutter ring 1 is subjected to a precision grinding process to obtain a finished product.

[0049]

[0050] Table 1

[0051]

Embodiment 2

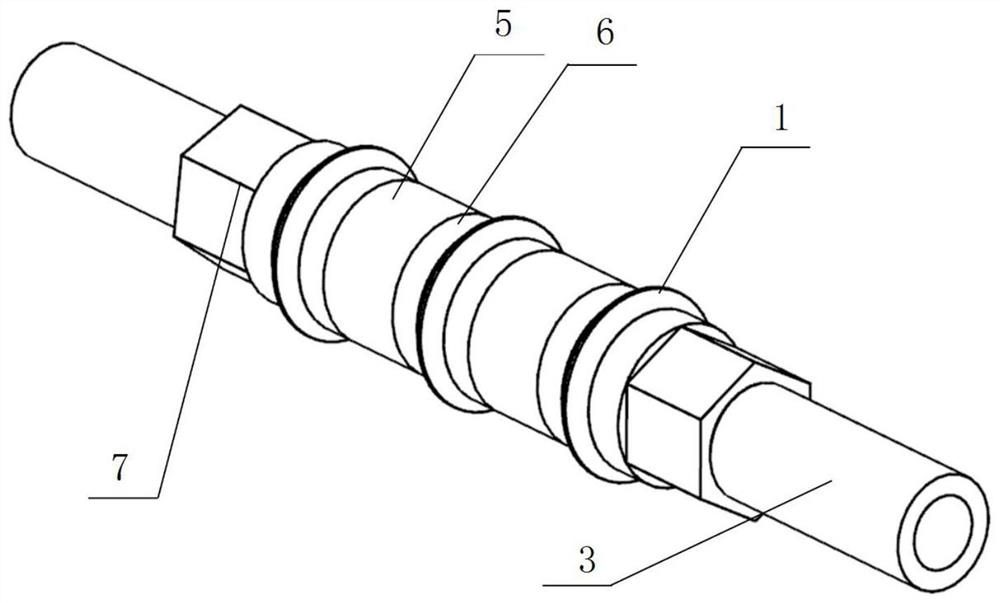

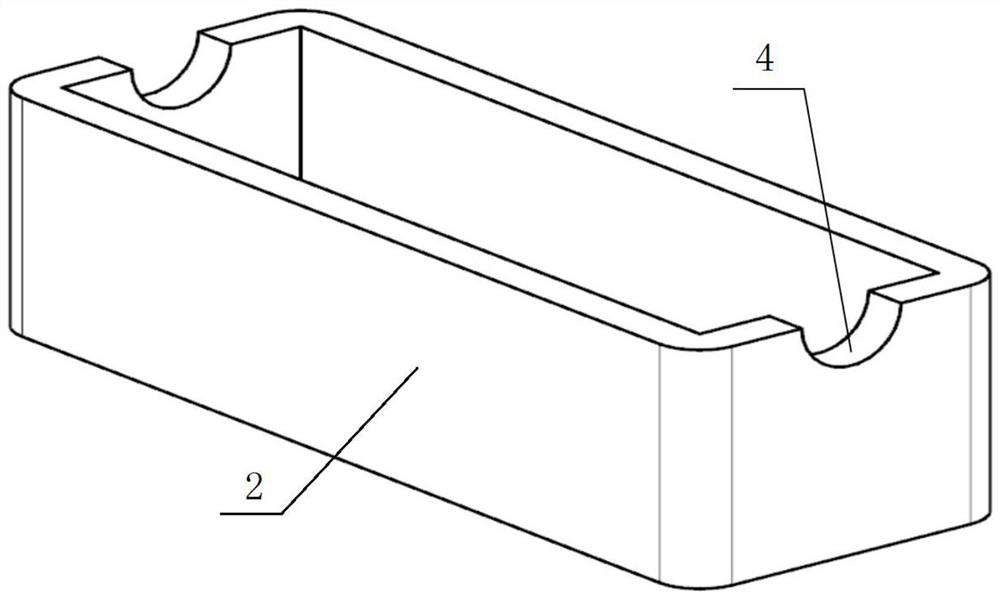

[0057] As shown in Figures 1 to 4, the present embodiment provides a process used in the heat treatment process of the above-mentioned shield machine cutter ring 1.

[0062] Further, the two ends of the fixed shaft 3 are provided with threads, and the fixing member is a nut 7 that cooperates with the threaded structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com