Textile fabric desizing device

A desizing device and a technology for textile fabrics, which are applied in the processing of textile materials, textile material carriers, and textile material containers, etc., can solve the problems affecting the coloring of textile fabrics, difficulty in dyeing and finishing, and low work efficiency, so as to improve Work efficiency, enhance the drying effect, and ensure the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

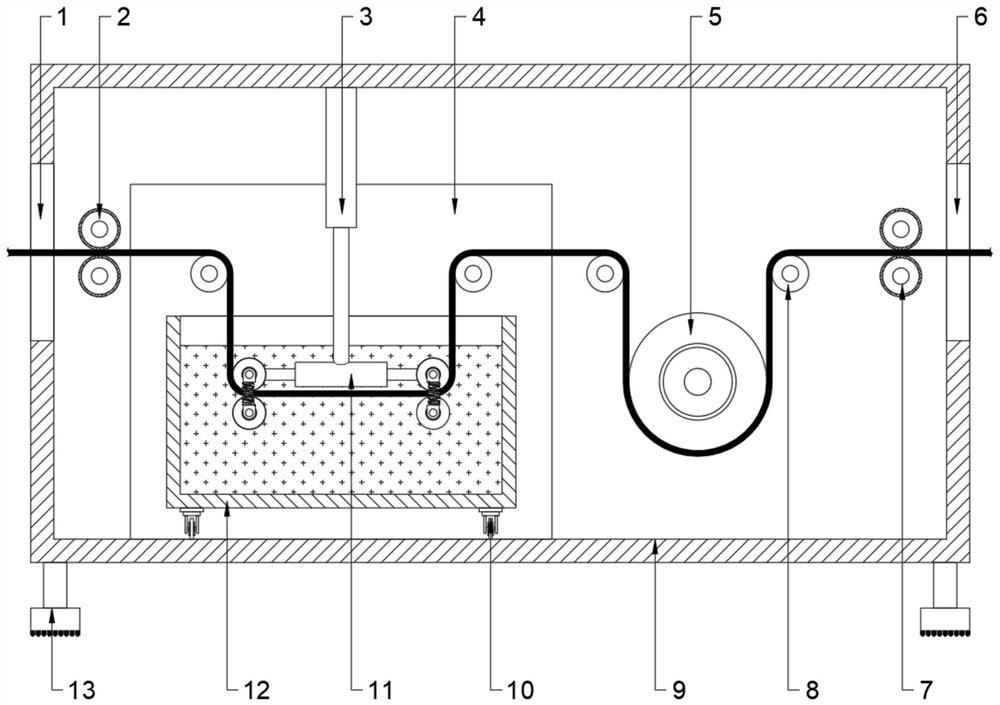

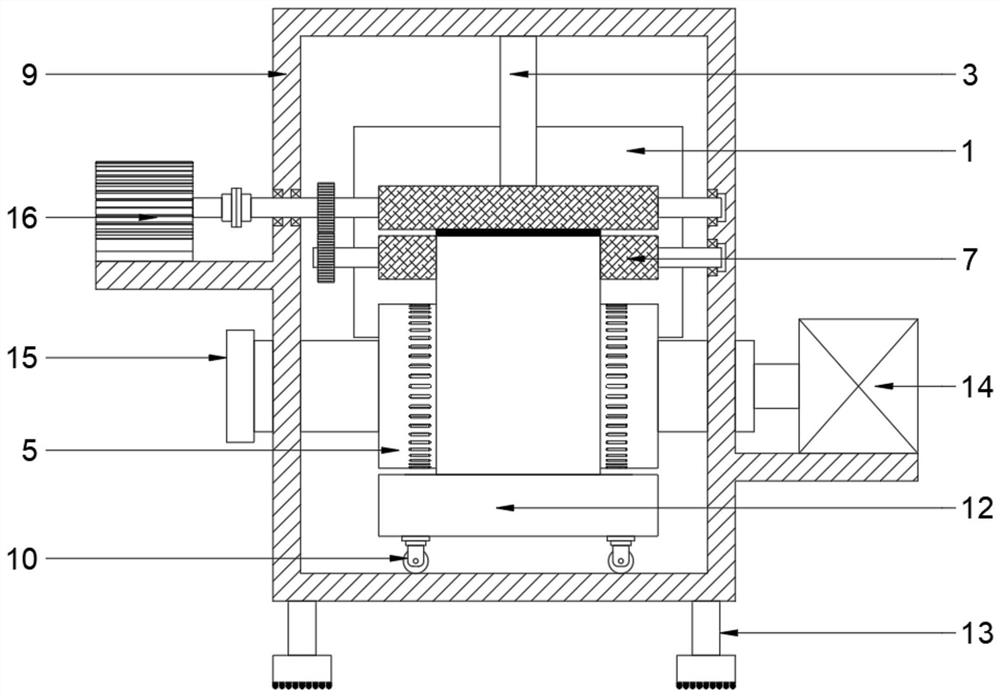

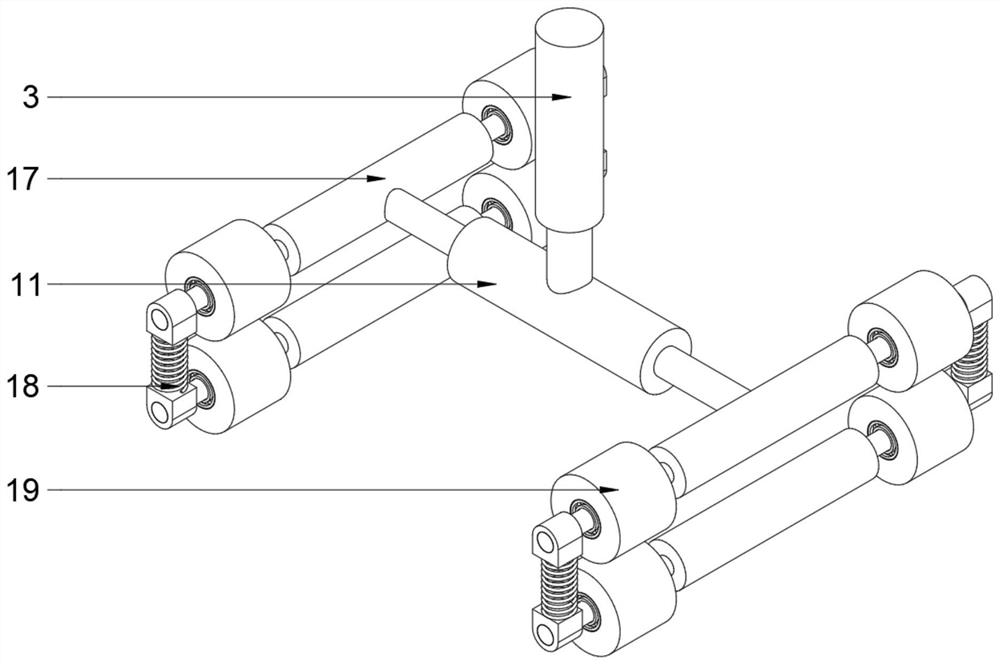

Embodiment 1

[0025] see Figure 1~4 , in an embodiment of the present invention, a textile fabric desizing device includes a box body 9 and a desizing assembly and a drying assembly arranged inside the box body 9, and the two sides of the box body 9 are respectively provided with a feed port 1 and a The discharge port 6 is convenient for the input and output of the fabric; the desizing assembly includes a lifting rod 3, a material storage box 12 and a clamping device, and the upper end of the lifting rod 3 is fixed on the top of the casing 9 and its lower end is connected with the clamping device Fixedly connected, the storage box 12 is arranged below the clamping device and contains desizing liquid inside; the clamping device includes a first two-way telescopic rod 11 and a second two-way telescopic rod 17, and the first two-way telescopic The rod 11 is fixedly mounted on the bottom of the elevating rod 3 and its two ends are provided with two sets of second two-way telescopic rods 17. T...

Embodiment 2

[0033] see figure 1 , 3 , in the embodiment of the present invention, a textile fabric desizing device is further improved on the basis of embodiment 1 in order to expand the scope of application of the device and enhance the practicability of the device. The improvement is that the connecting member 18 It consists of connecting springs and connecting blocks. The connecting blocks are in two groups and fixedly installed at both ends of the connecting springs respectively. The connecting blocks are provided with mounting holes and the mounting holes are fixed to the protruding end of the second two-way telescopic rod 17. The connection utilizes the elasticity of the connecting spring, so that the distance between the two sets of second two-way telescopic rods 17 connected together through the connecting piece 18 can change with the thickness of the fabric, which is suitable for desizing fabrics of different thicknesses and is flexible Strong.

[0034] The working principle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com