Fly ash carbon content rapid measurement device and method with automatic calibration function

A fly ash carbon content, automatic calibration technology, used in measuring devices, sampling devices, engine lubrication and other directions, can solve the problem of unguaranteed measurement accuracy, achieve simple structure, avoid pollution of the site environment, and accurate and accurate measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

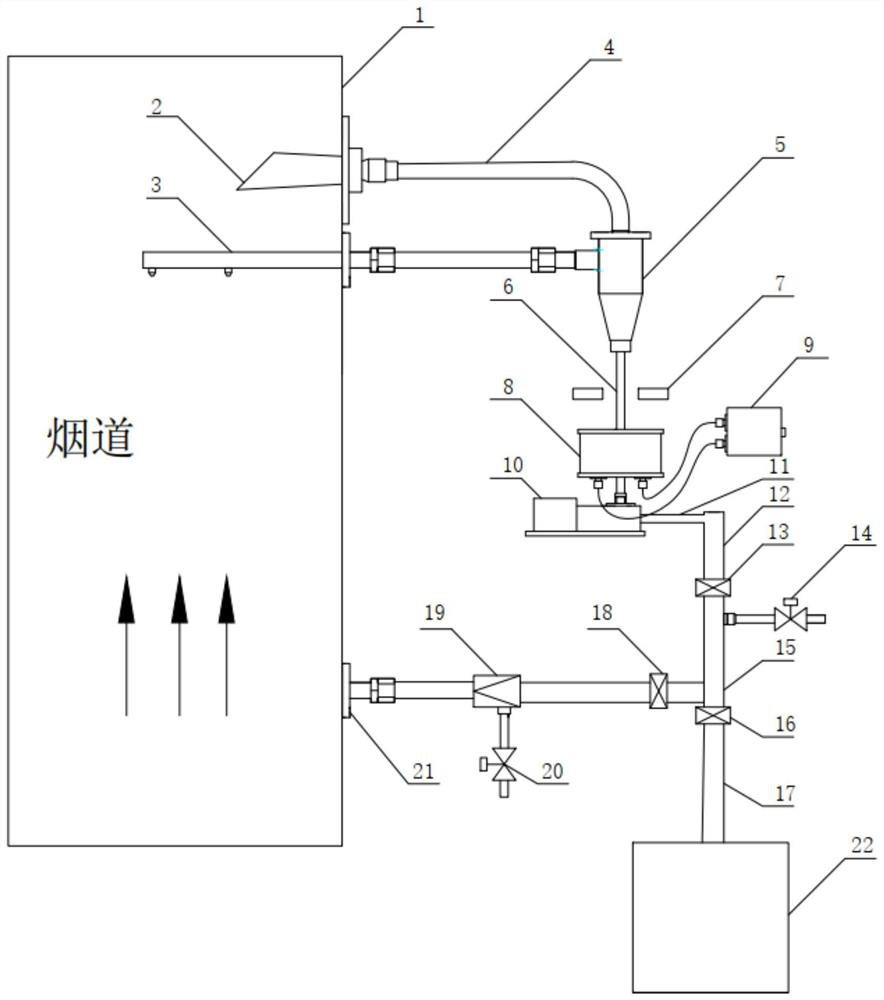

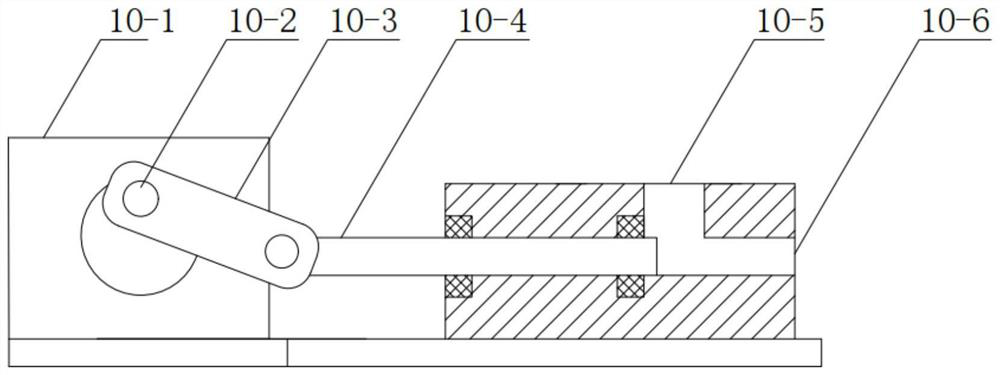

[0049] A fast measuring device for carbon content in fly ash with automatic calibration function, such as figure 1 As shown, it includes a sampling unit, a microwave measuring unit, a feeding unit, an ash sample transmission unit, a powder returning unit, a burnt fly ash measuring instrument 22 and a program controller. in:

[0050] 1) One end of the sampling unit extends into the flue 1, and the other end is connected with the microwave measuring unit. The sampling unit adopts a self-pumping sampler without external power, including a Rafal injector 2, a sampling pipe 3, an air induction pipe 4 and a cyclone separator 5. Among them, the Rafal injector 2 is clamped on a wall in the flue 1, the injection port of the Rafal injector 2 is an oblique opening, and the opening faces away from the smoke flow direction, and the Rafal injector 2 The center of the nozzle is connected with the top of the cyclone separator 5 through the air induction pipe 4 . The sampling pipe 3 is clam...

Embodiment 2

[0065] A method for quickly measuring the carbon content of fly ash with an automatic calibration function, comprising the following steps:

[0066] Step 1: Power on the system, program control to close the ash storage valve 13, the sampling valve 16, open the ash discharge valve 18, the jet solenoid valve 20, the jet aspirator 19 produces suction, open the ash discharge solenoid valve 14, and compress Air enters the middle discharge chamber 15, and under the joint action of the jet air extractor 19, all the ash samples in the middle ash storage chamber 15 are returned to the flue 1, thereby emptying the ash samples in the middle storage chamber 15 .

[0067] The second step: close the jet solenoid valve 20, open the ash storage valve 13, empty out all the ash samples in the ash sample discharge pipe 11, the motor feeder 10, and the microwave measuring tube 6, then close the ash discharge solenoid valve 14, close Ash storage valve 13.

[0068] Step 3: Wait for the ash sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com